Quick disassembly and assembly device for piston ring of cylinder sleeve movable optical engine

An optical engine, piston ring technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of limited installation space and unusable piston rings, and achieve the effect of improving efficiency, saving costs, and quick disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

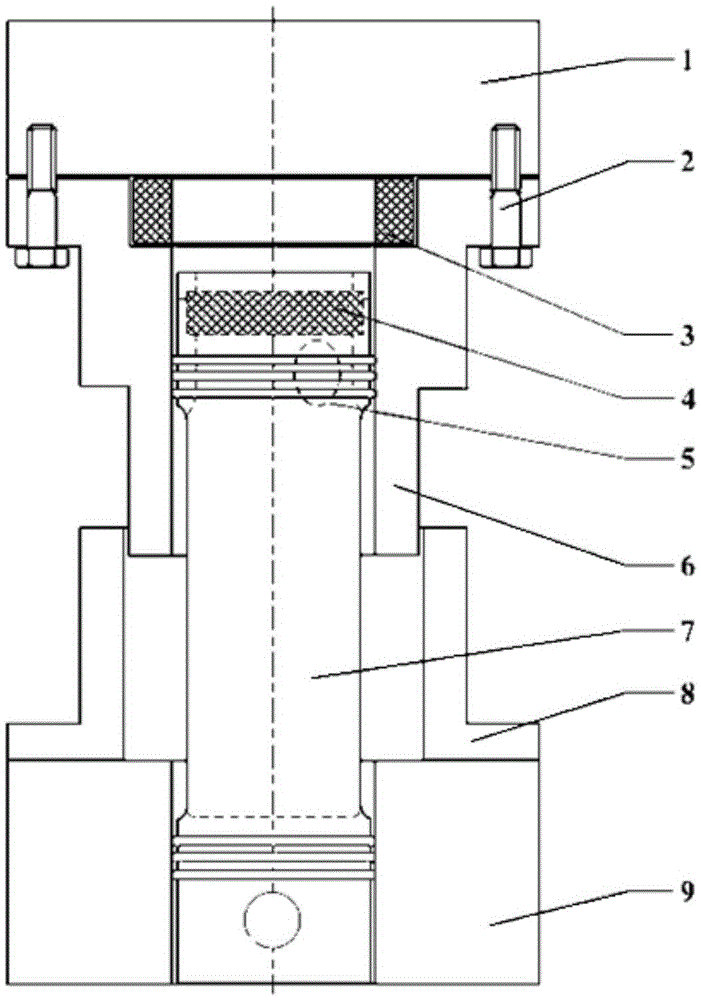

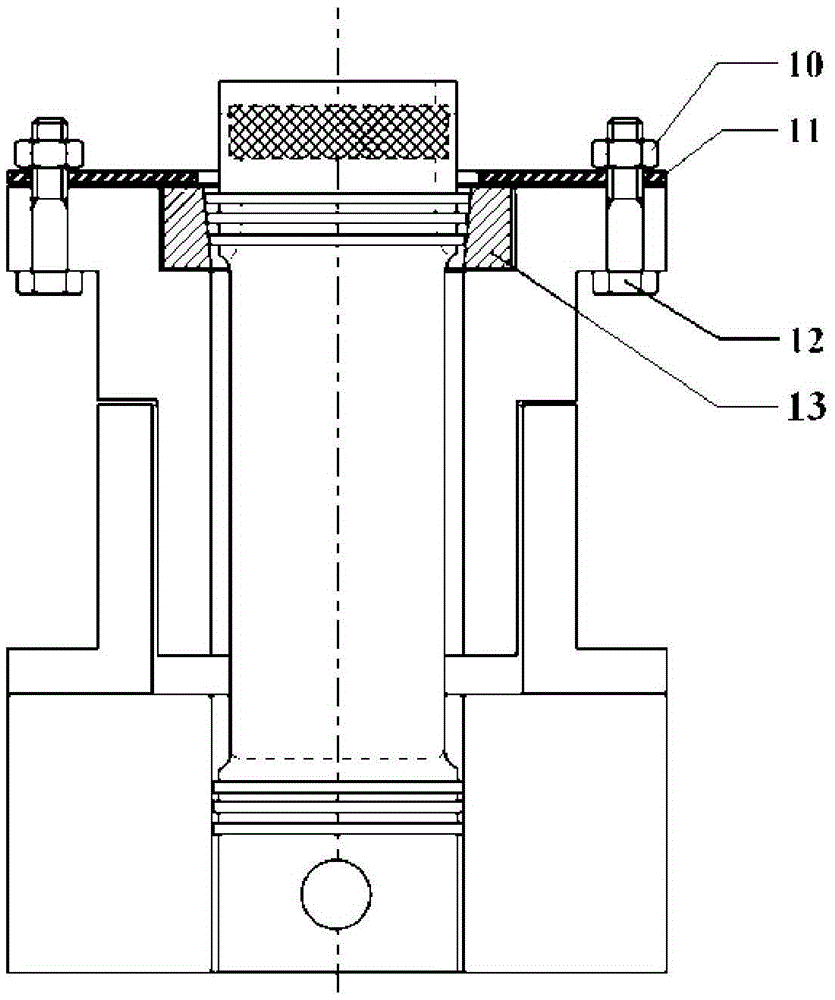

[0022] Such as Figure 1 to Figure 6 As shown, a cylinder liner movable optical engine piston ring quick disassembly device is composed of a device body, including a guide ring 13, a thrust washer 11, a fastening bolt 12 and a nut 10, and the outer diameter d of the guide ring 13 is 1 and height h 1 The same as the quartz glass window 3 fixed on the cylinder liner 6, it is ensured that the guide ring 13 can replace the annular quartz glass window 3. The middle part of the guide ring 13 is provided with a tapered through hole, and the original quartz glass window 3 and the cylinder liner 6 ring are used. The positioning relationship between the grooves keeps the tapered through hole coaxial with the cylinder liner 6; the diameter d at the bottom of the tapered through hole 3 It is the same as the inner diameter of the cylinder liner 6, ensuring that each piston ring in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com