Cutting device

A technology for cutting devices and cutting knives, which is applied in feeding devices, metal processing machinery parts, metal processing, etc., can solve problems such as increased costs, residual materials, unfavorable maintenance, etc., to achieve faster operation, safe and reliable operation, and solve residual problems Even the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

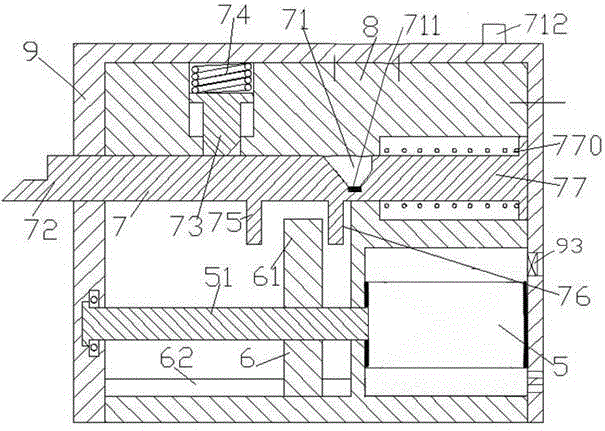

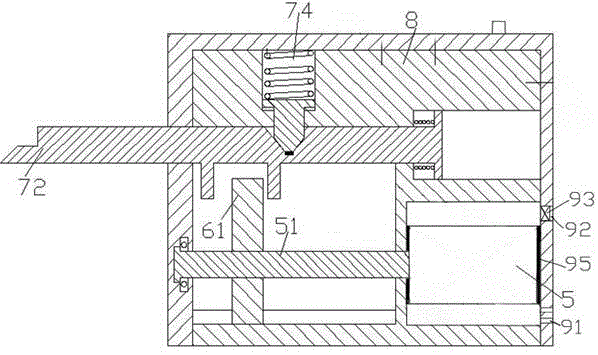

[0010] Combine below Figure 1-2 The present invention will be described in detail.

[0011] A cutting device according to an embodiment comprises a support body 8 fixedly provided with a housing 9, the support body 8 is slidably mounted with a cutting knife bar 7, and the cutting knife bar 7 includes a A cutting head 72 for cutting, a notch 71 located on the upper side of the cutting bar 7, a right protruding portion 76 and a left protruding portion 75 located at the lower side of the cutting bar 7, And the engaging end portion 77 used to engage with the shell 9 at the right end, the engaging end portion 77 is also engaged with the pressing elastic member 770 so that the engaging end portion 77 of the cutting knife bar 7 can be Biased against the shell 9, the supporting body 8 is provided with a wedge-shaped plate 73 corresponding to the notch 71, which can slide up and down and is pressed against the cutting knife bar 7 by an elastic pressing spring 74, The lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com