Protection film with glittering and antistatic effects and preparation method thereof

An antistatic and protective film technology, applied in chemical instruments and methods, devices for coating liquids on surfaces, synthetic resin layered products, etc. The effect of antistatic, preventing loss and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] Antistatic agent: external coating antistatic agent of Weihai Yunqing Chemical;

[0052] Substrate: Toray's 50μm and 100μm PET substrates;

[0053] Glitter powder: Pearlescent powder from Hongtai Pigment Store in Houjie, Dongguan City.

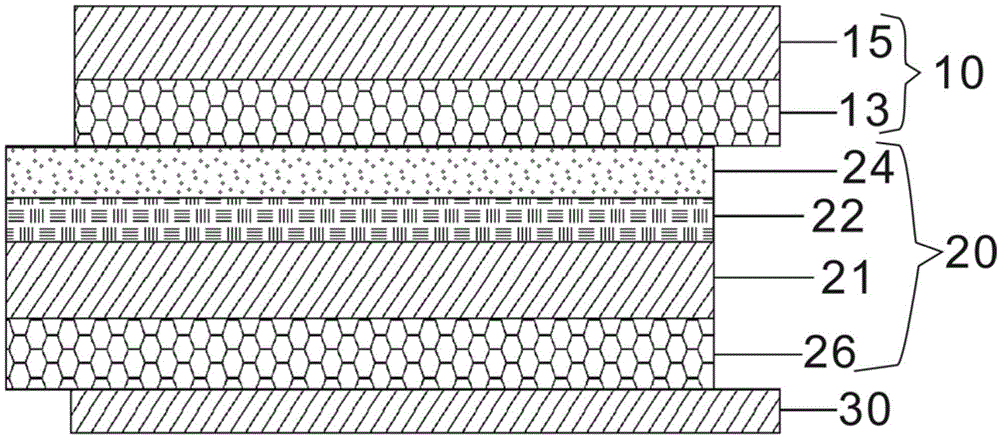

[0054] The antistatic agent was coated on the B substrate 21 by an anilox roller, and baked at 80°C for 60s to obtain the antistatic layer 22 . Wherein the thickness of the antistatic layer 22 is 2 μm, and the thickness of the B substrate 21 is 100 μm;

[0055] Apply the UV resin on the surface of the antistatic layer 22 through a micro-gravure roller, dry at 100°C for 60s, and then cure with a UV lamp with an energy of 500mJ / cm2 to obtain the UV hardened layer. Wherein the thickness of the UV curable layer 24 is 5±1 μm;

[0056] Add 5 / 10,000 flash powder to the silicone pressure-sensitive adhesive, filter it through a 25μm filter element and a 5μm filter element, and then apply the glue on the other side of the B substrate 21 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com