Erecting composite beam on-site section splicing girder construction technology of double guide beam bridge erecting machine

A construction process and technology of bridge erection machines, which are applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of high safety risk, high cost, and large amount of foundation construction work, and achieve high installation accuracy, construction safety, The construction effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. Support design and construction

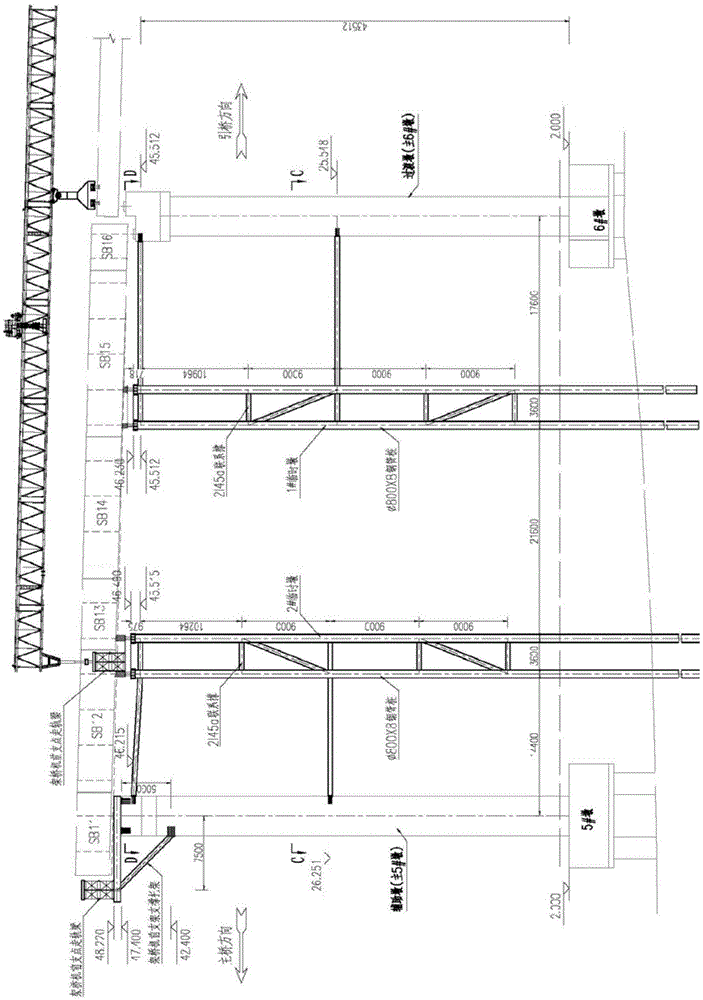

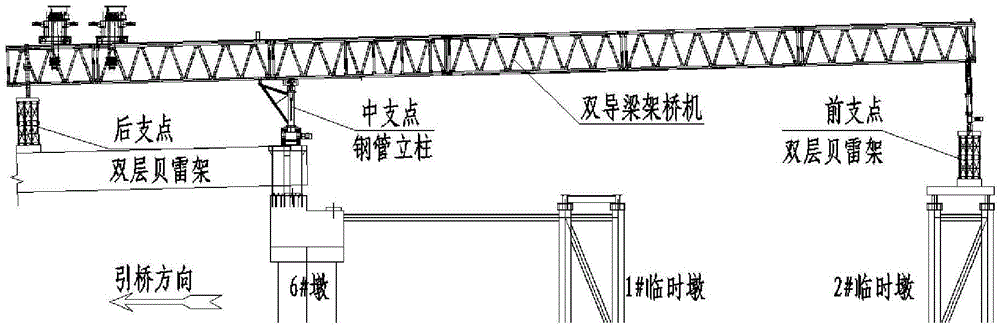

[0027] 1.1 as figure 1 with 2 As shown in the figure, steel pipe piles are used to form a temporary pier for the assembled support, and a supporting system is formed with the auxiliary pier and transition pier.

[0028] Auxiliary piers in the direction of the main bridge ( figure 1 Main 6# pier), transition pier in approach bridge direction ( figure 1 There are at least two temporary piers between the main 5# piers). For the convenience of description, the temporary piers are respectively 1# temporary piers and 2# temporary piers, and the temporary piers will be removed after the bridge structure construction is completed. The sequence is transitional pier, 1# temporary pier, 2# temporary pier and auxiliary pier.

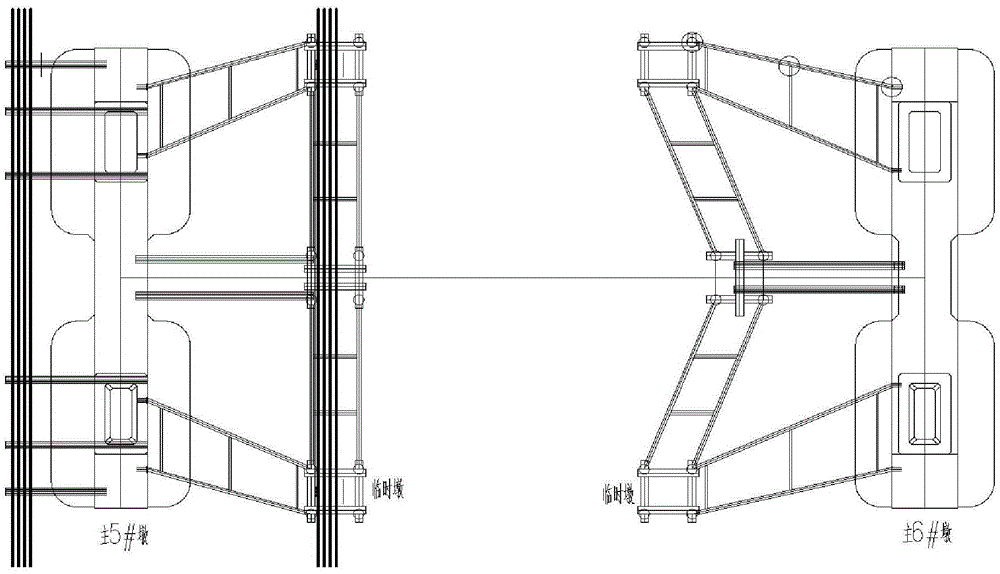

[0029] 1.2 as figure 2 As shown, after the steel pipe piles are driven into the soil, a section steel stacking platform is set on the top of each temporary pier for loading and preloading. The section steel is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com