AIO lift pump station

An all-in-one, pumping station technology, applied in the construction, building structure, construction material processing and other directions, can solve the problems of non-leakage, affecting the surrounding environment, loud noise, etc., to extend the service life, prevent noise pollution, seal Good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

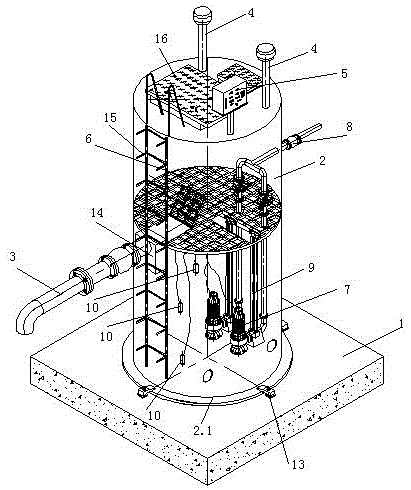

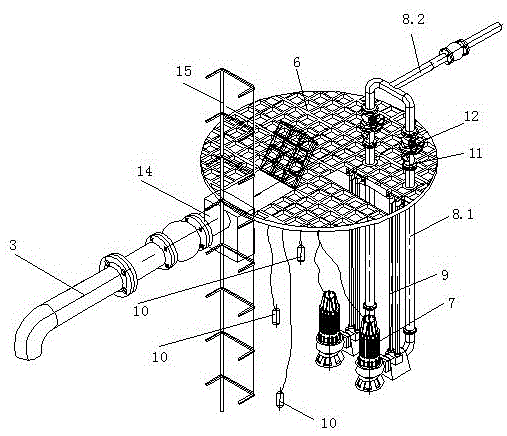

[0015] Embodiment 1: an integrated lifting pump station, including a cylinder body 2 that is poured at the bottom and arranged on a reinforced concrete base 1, a water inlet pipe 3 arranged on one side of the cylinder body 2, and a ventilation pipe arranged at the top of the cylinder body 2 4. Control cabinet 5, inspection port 16, an inspection platform 6 is arranged in the middle of the cylinder body 2, the inspection platform 6 is composed of several pieces of glass fiber reinforced plastic grid plates spliced together, the water inlet pipe 3 is arranged under the inspection platform 6, and the Two screw centrifugal pumps 7 are arranged side by side near the bottom of cylinder body 1. Screw centrifugal pump 7 is electrically connected to control cabinet 5. Outside the body 2, the screw centrifugal pump 7 is additionally provided with a guide rod coupler 9 connected vertically upward to the maintenance platform 6. Liquid level controllers 10 are installed at three heights ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com