Integrated control system and device for drilling operation procedures

A process integration and drilling operation technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problem that the automation degree and operation efficiency of the system cannot be further improved, the system operation process is not strong, and it cannot be well Ensure operational safety and operational efficiency, etc., to achieve the effect of improving the level of automatic operation, reducing misoperation, and improving the level of automatic cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

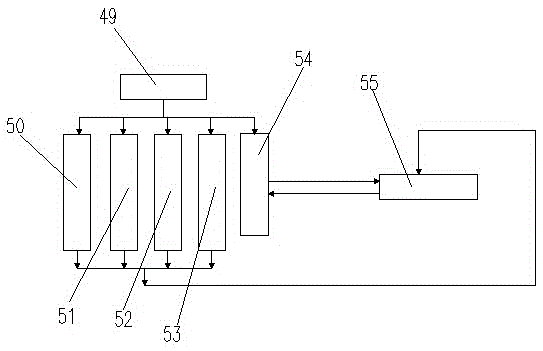

[0021] Pull-out mode 50 under master driller control mode 49

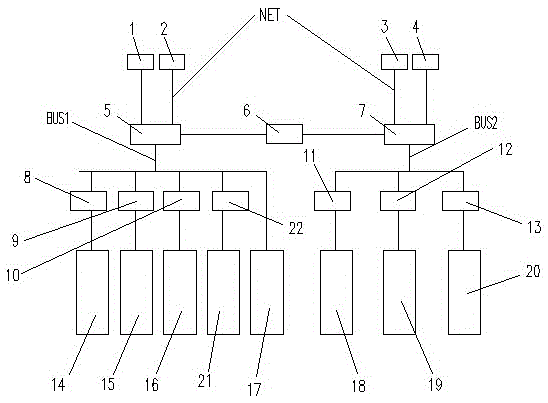

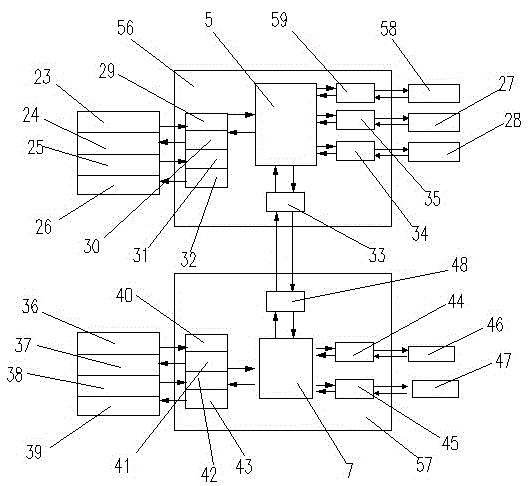

[0022] See attached Figure 1-3, set the system on No. 1 industrial machine 1 or No. 2 industrial machine 2 to the tripping mode 50, and the tripping mode 50 set by No. 1 industrial machine 1 or No. 2 industrial machine 2 is transmitted to the master driller CPU5 through the NET network , the master driller CPU5 transmits the tripping pattern 50 to the assistant driller CPU7 by connecting the network coupler 6, and the assistant driller CPU7 transmits the tripping pattern 50 signal to No. 3 industrial machine 3 or No. 4 industrial machine 4 through the NET network, After the transmission is completed, the tripping mode 50 automatically enters the main driller's operation panel 25 and the assistant driller's operation panel 38 through the main driller's digital input (DI) module 31 and the assistant driller's digital input (DI) module 42 respectively. In the drilling mode 50, the main driller CPU5 transmits the sig...

Embodiment 2

[0024] Drill down mode 51 under master driller control mode 49

[0025] see Figure 1-3 , set the drill-down mode 51 on No. 1 industrial machine 1 or No. 2 industrial machine 2, and the drill-down mode 51 set by No. 1 industrial machine 1 and No. 2 industrial machine 2 is transmitted to the master driller CPU5 through the NET network, Then it is transmitted to the assistant driller CPU7 by connecting the network coupler 6, and the assistant driller CPU7 transmits the signal to No. 3 industrial machine 3 or No. 4 industrial machine 4 through the NET network. The Driller Digital Input (DI) module 31 and the Assistant Driller Digital Input (DI) module 42 enter the Master Driller Operations Panel 25 and the Assistant Driller Operations Panel 38 . In the down-drilling mode 51, the main driller CPU5 transmits the high gear signal to the remote station 17 of the valve island through the BUS1 network. Driller CPU5, and the signal is input to the electronic brake device 58 through th...

Embodiment 3

[0027] Build Root Mode 53 in Master Driller Control Mode 49

[0028] see Figure 1-3, set and establish the root mode 53 on No. 1 industrial machine 1 or No. 2 industrial machine 2, transmit it to the main driller CPU5 through the NET network, and then transmit it to the assistant driller CPU7 by connecting the network coupler 6, and the assistant driller CPU7 passes NET network transmits the signal to No. 3 industrial machine 3 or No. 4 industrial machine 4. After the transmission is completed, the root mode 53 is established and automatically passed through the main driller digital input (DI) module 31 and the assistant driller digital input (DI) module 42 respectively. Access the master driller's operating panel 25 and the assistant driller's operating panel 38 . Under the establishment of root mode 53, the main driller CPU5 transmits the high gear signal to the valve island remote station 17 through the BUS1 network. Drill CPU5, chief driller's analog output (AO) module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com