Modular LED panel light

A technology of LED panel lights and backlight modules, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of unstable overall structure of panel lights, single shape and structure, poor heat dissipation effect, etc., to achieve Effects of richness, soft light, and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

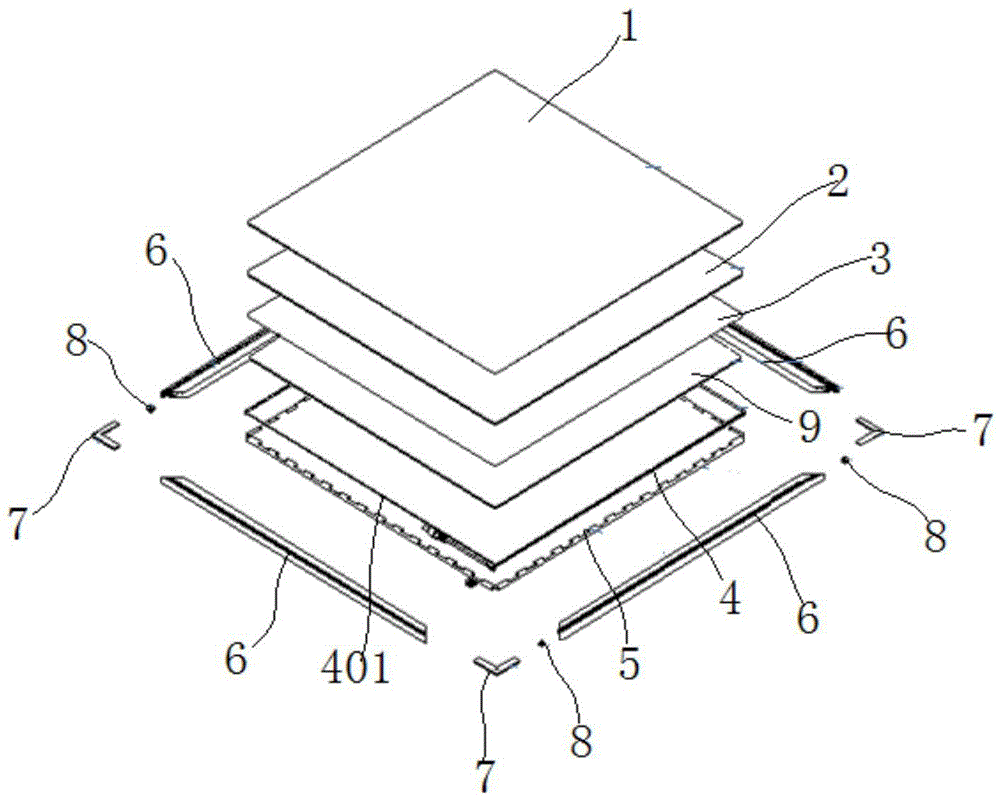

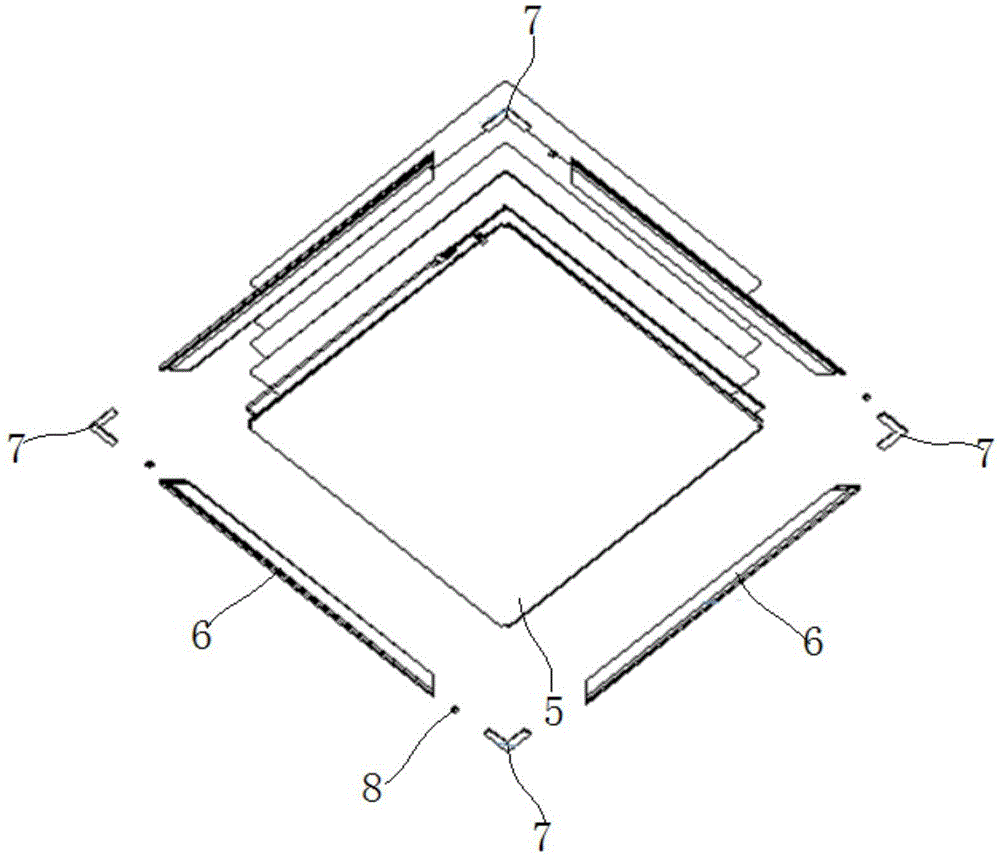

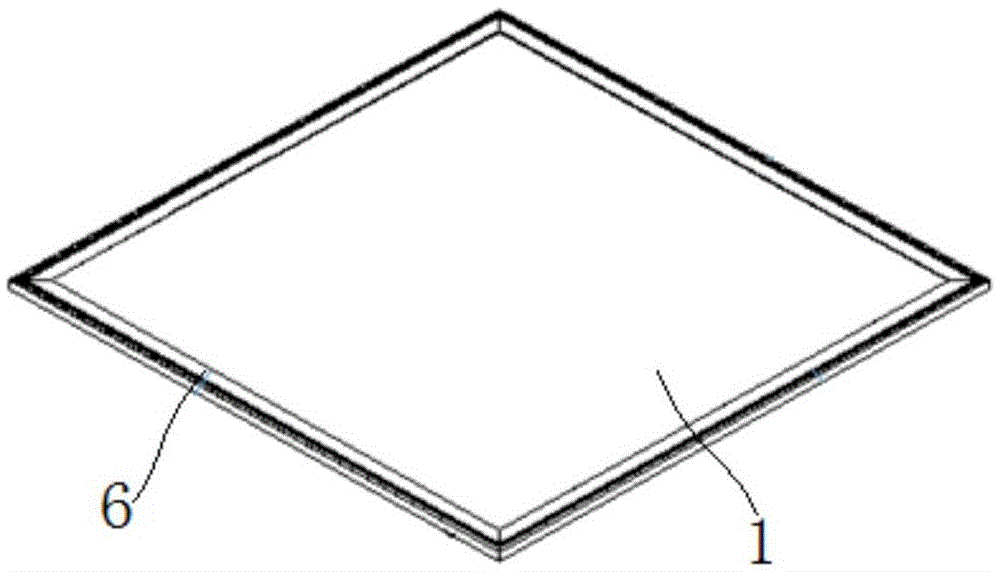

Embodiment 1

[0042] With reference to the accompanying drawings, a modular LED panel light of this embodiment includes a backlight module, a frame 6 and a heat dissipation back cover 5 located at the bottom of the backlight module, wherein the backlight module is wrapped in the heat dissipation back cover 5 and the edge of the heat dissipation rear cover 5 is accommodated in the installation groove 603 inside the frame 6 . Such as Figure 5 , Image 6 As shown, the above-mentioned heat dissipation rear cover 5 includes a heat dissipation bottom plate 503, a heat dissipation frame 502, and heat dissipation teeth 501 uniformly distributed along the circumference of the top of the heat dissipation rear cover 5. The heat dissipation teeth 501, the heat dissipation frame 502 and the heat dissipation bottom plate 503 together form a housing space for the backlight module. Such as figure 1 , figure 2 As shown, the backlight module of this embodiment includes a PCB light bar 4, a diffuser pla...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the ratio of the distance between the heat dissipation fins 501 on the same side of the heat dissipation rear cover 5 to the length of the heat dissipation fins 501 is 0.8.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the ratio of the distance between the heat dissipation fins 501 on the same side of the heat dissipation rear cover 5 to the length of the heat dissipation fins 501 is 0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com