Patents

Literature

37results about How to "Good for injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

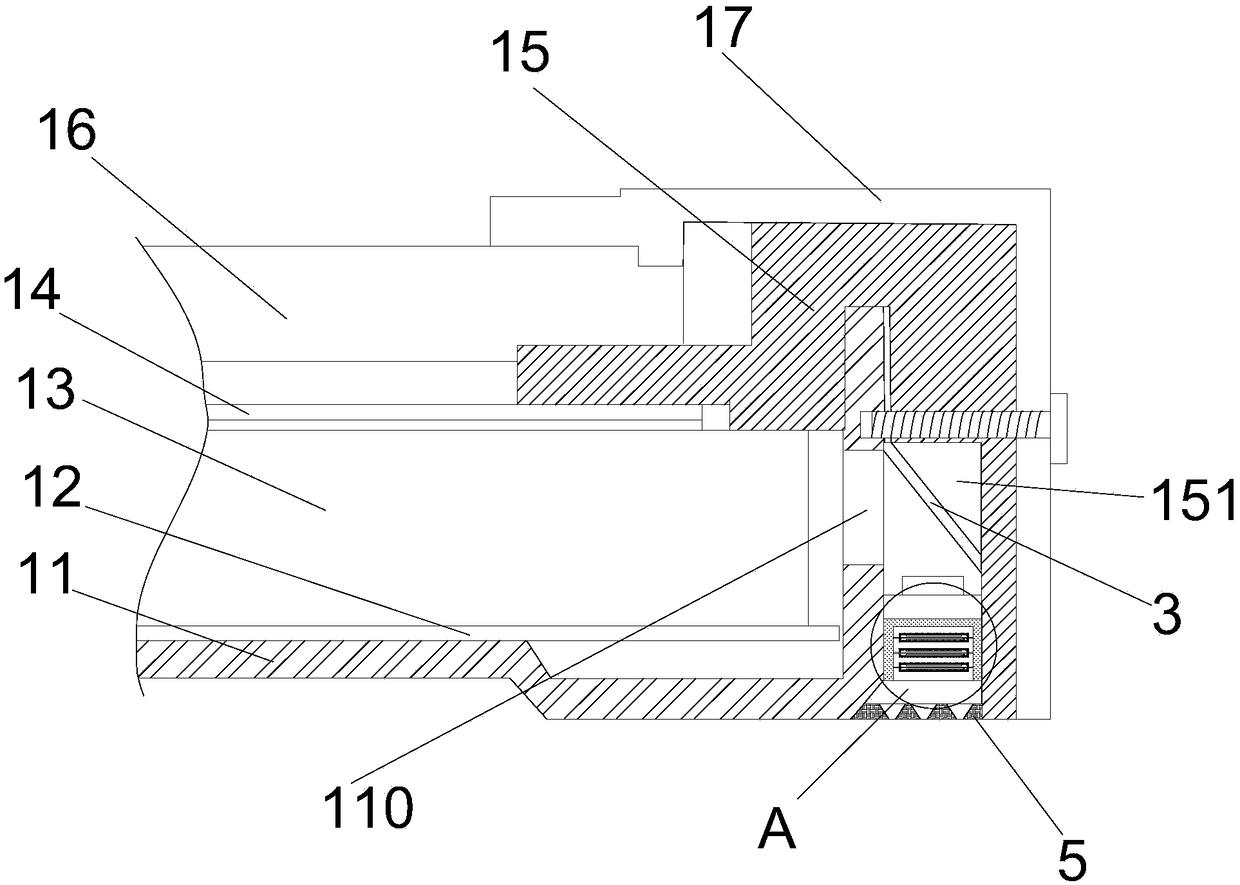

Light emitting diode (LED) lamp optical lens

InactiveCN102313244AWide versatilityWide exposure areaPoint-like light sourceRefractorsLED lampLight-emitting diode

The invention discloses a light emitting diode (LED) lamp optical lens, which comprises a collimation lens, wherein the side face of the collimation lens is a total reflection face; a light outlet face of the collimation lens is provided with a sheet lens; the sheet lens consists of concave faces of a plurality of rectangular concave micro lenses; and the collimation lens is provided with a refraction groove at an end plane opposite to the light outlet face of the collimation lens. Through the combination of the collimation lens and the sheet lens, light which passes through the LED lamp optical lens is softened and distributed uniformly and does not glare and the light source illumination range is expanded.

Owner:中国科学院宁波材料技术与工程研究所湖州新能源产业创新中心

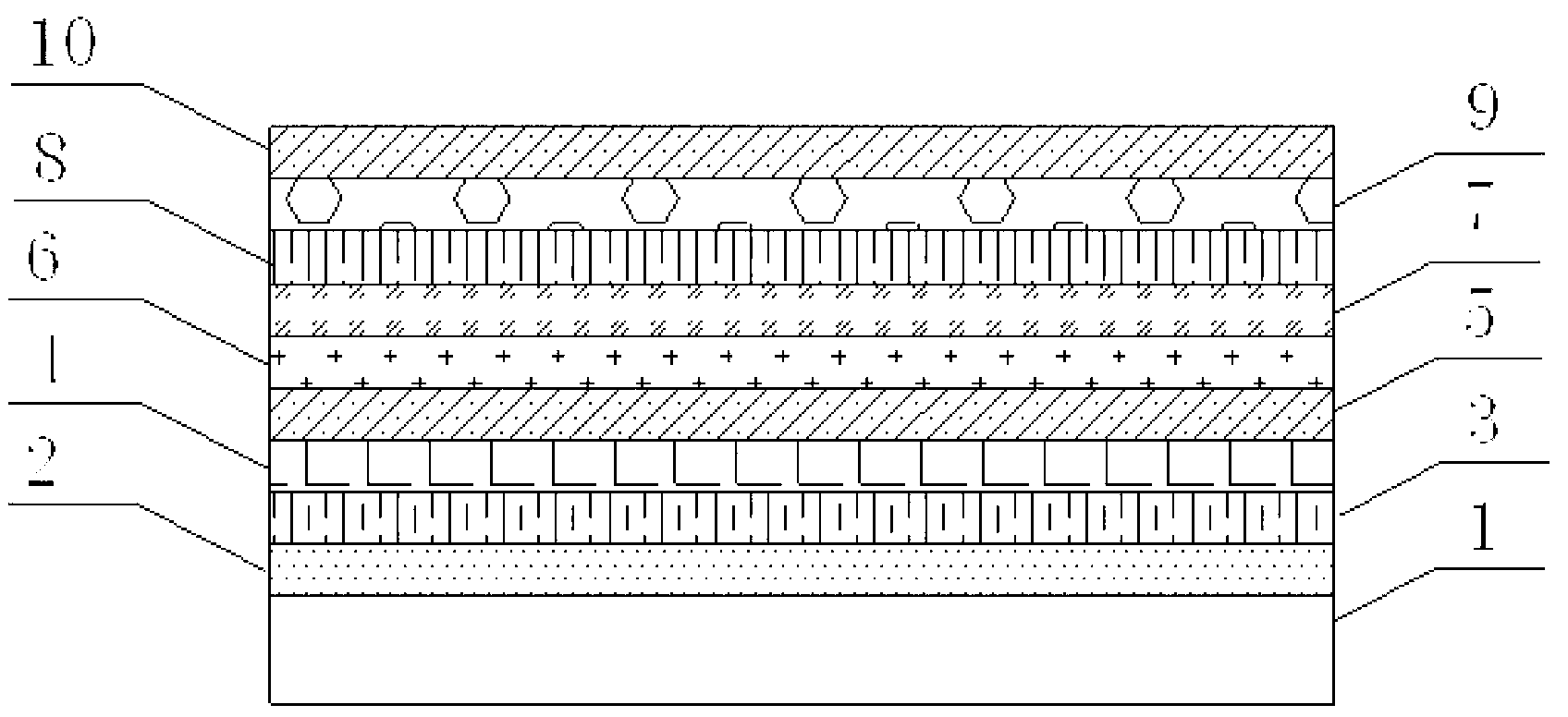

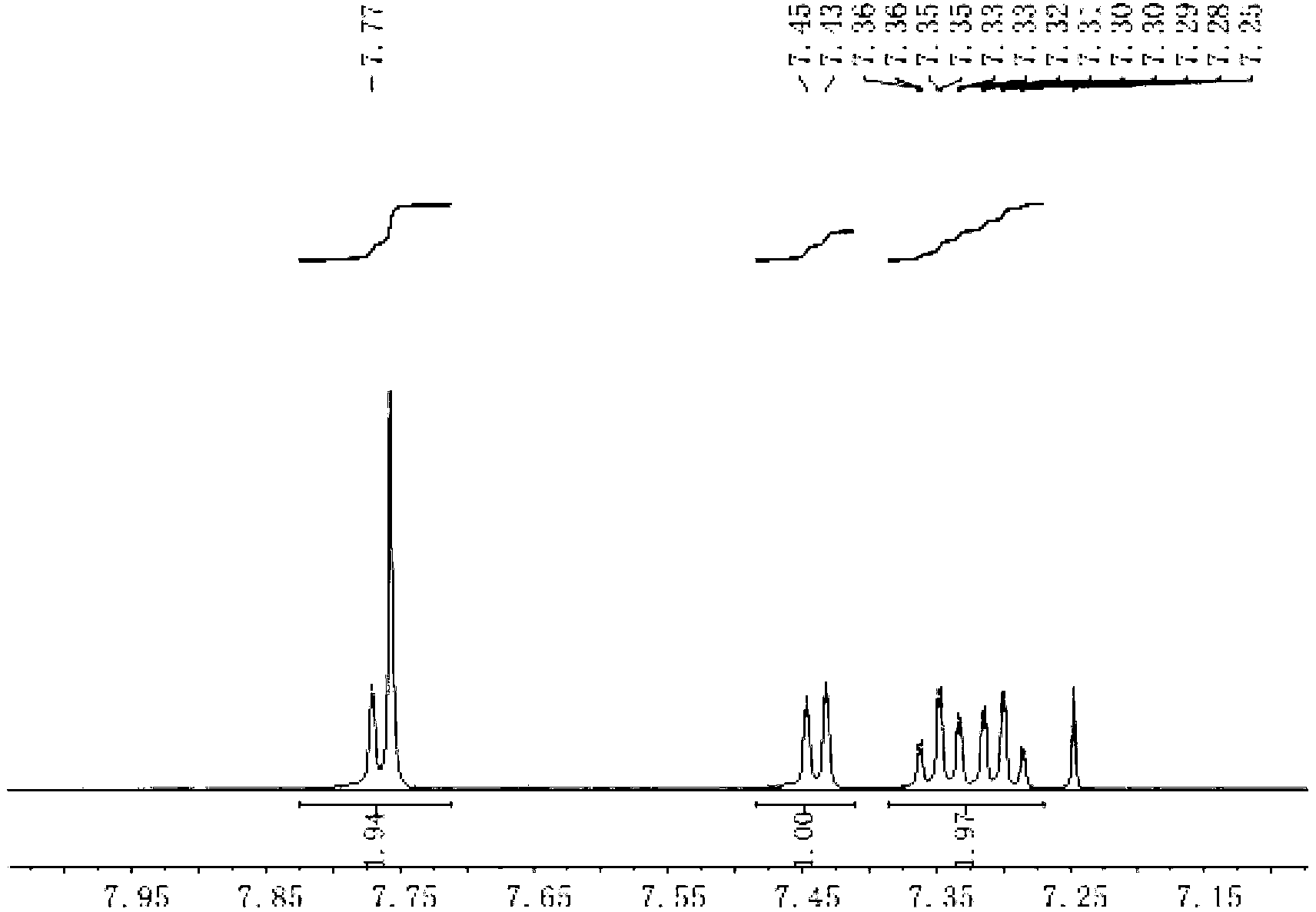

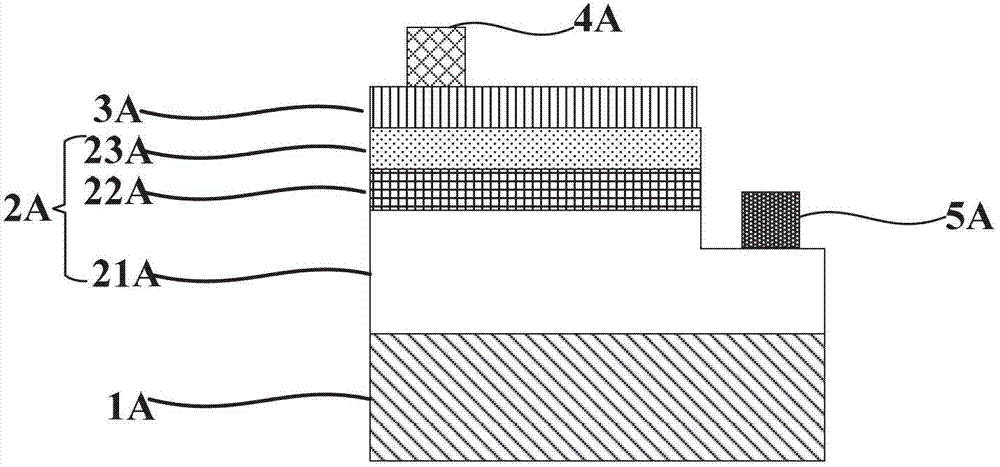

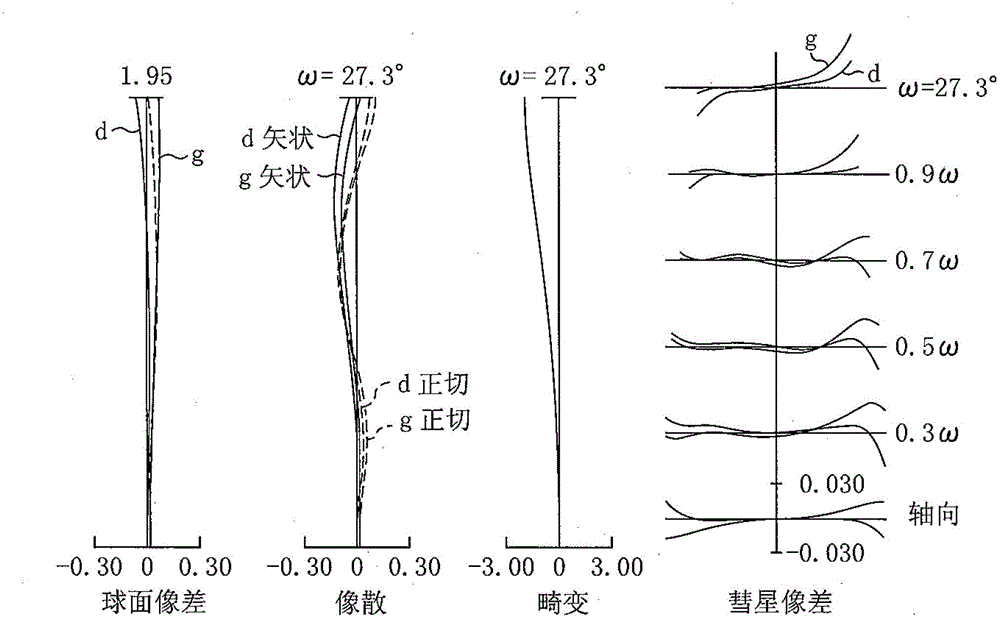

Organic light-emitting diode (OLED) device

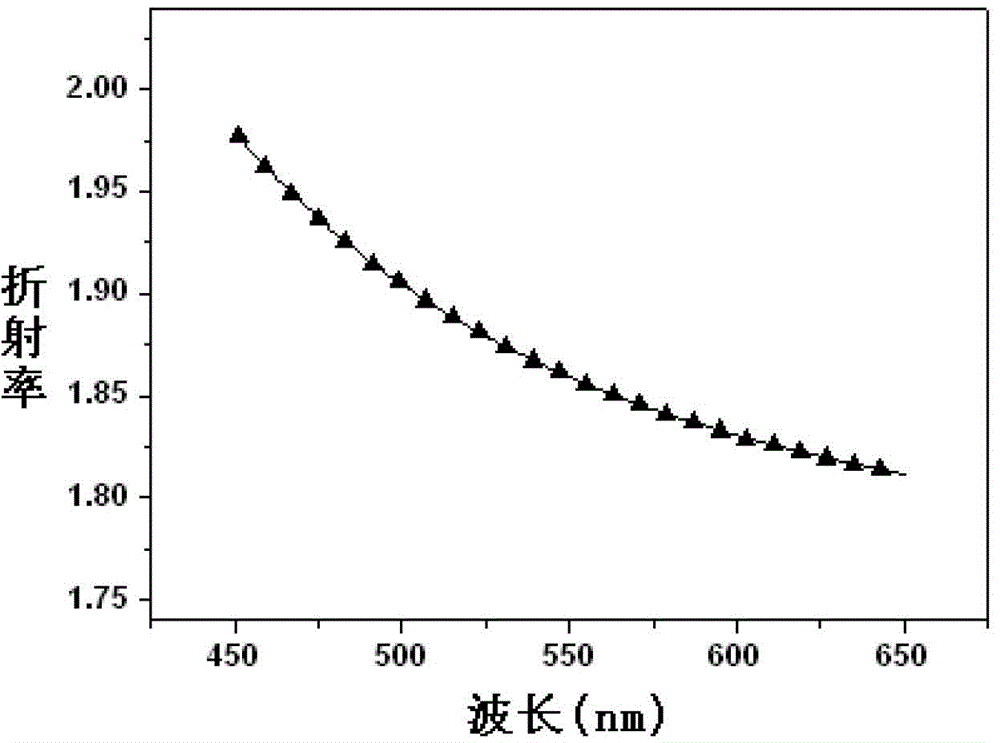

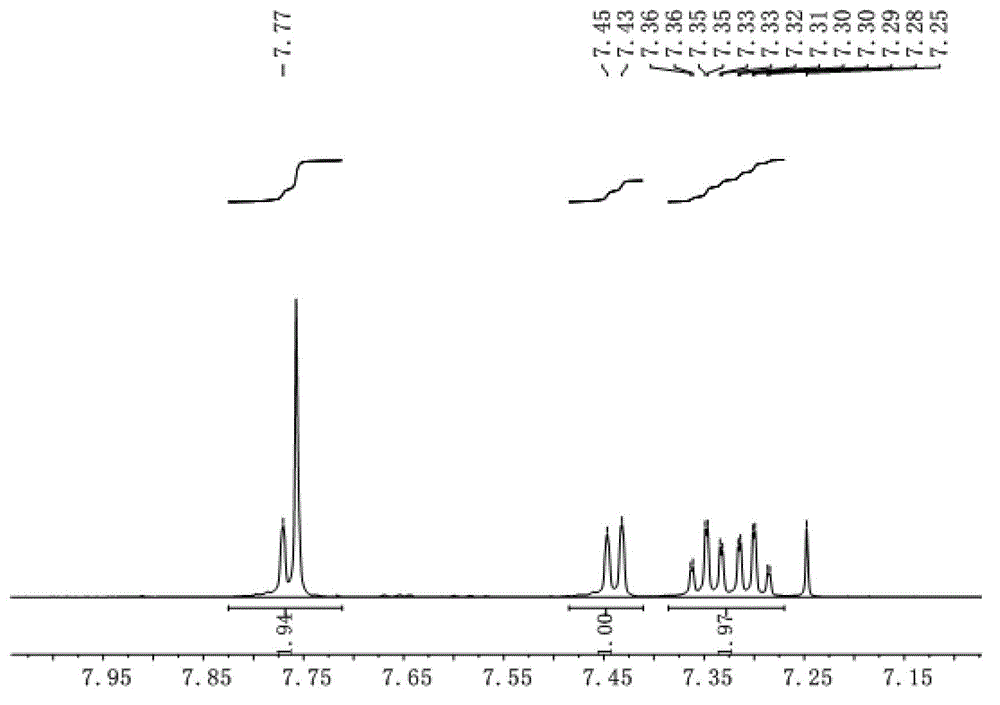

ActiveCN103022377AAvoid reduction of outgoing light intensityImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMagnesiumComposite cathode

The invention relates to an organic light-emitting diode (OLED) device which comprises a substrate and an anode, an organic layer and a cathode which are sequentially arranged on the substrate. The cathode is a transparent composite cathode and comprises an alloy layer of low work function metal and silver, a silver layer and an anti-reflection layer arranged on the silver layer. The work function of the low work function metal is smaller than 3.7eV, the molar ratio of the low work function metal and the silver in the alloy layer is 2:1-8:1, the thickness of the alloy layer is 3-11nm, the thickness of the silver layer is 15-30nm, and the thickness of the anti-reflection layer is 30-100nm. Magnesium, lithium, potassium and the like can be wrapped on the periphery of silver atoms when being evaporated with the silver together, the work function of the cathode can be effectively reduced by evaporation in proper proportion, and the cathode cannot absorb a large amount of visible light. The anti-reflection layer increases intensity of transparent light, is large in energy gap and does not affect color purity of the device. The thickness of the alloy layer and the silver layer is low, so that the alloy layer and the silver layer have high light transmittance.

Owner:KUNSHAN VISIONOX DISPLAY TECH +2

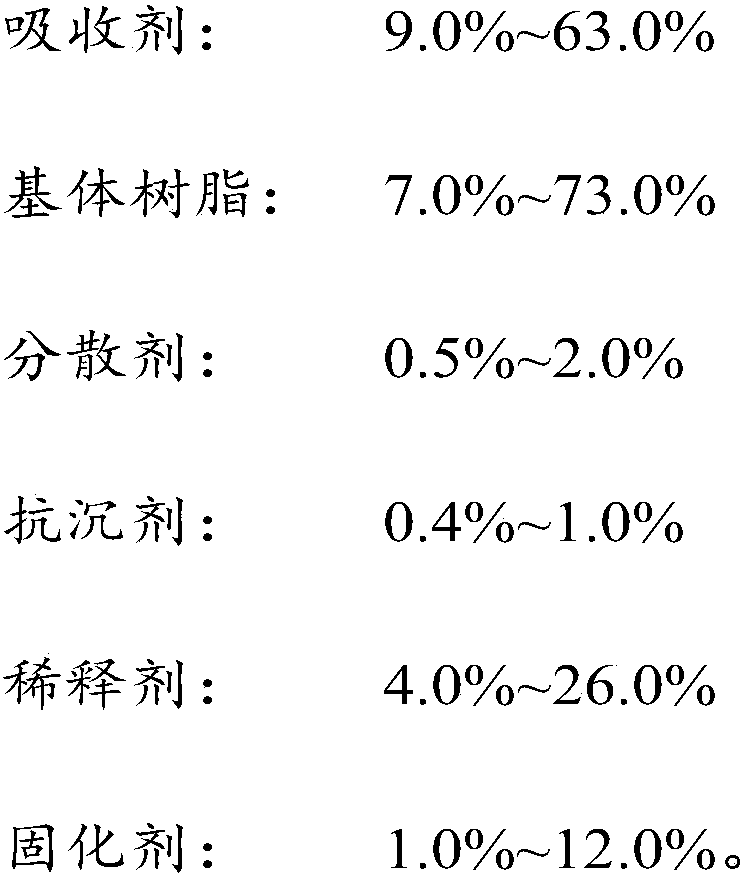

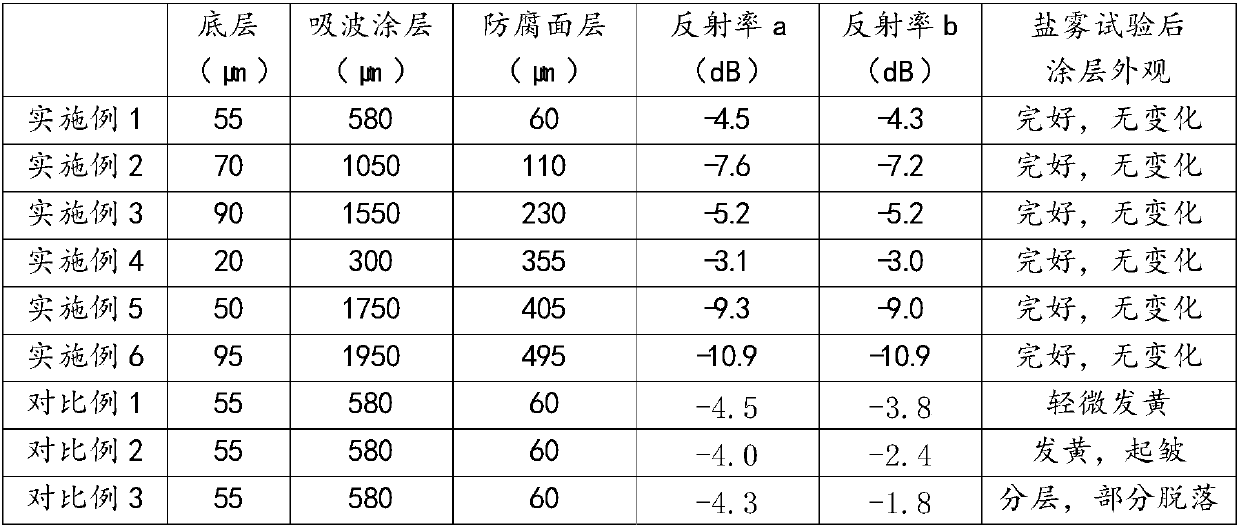

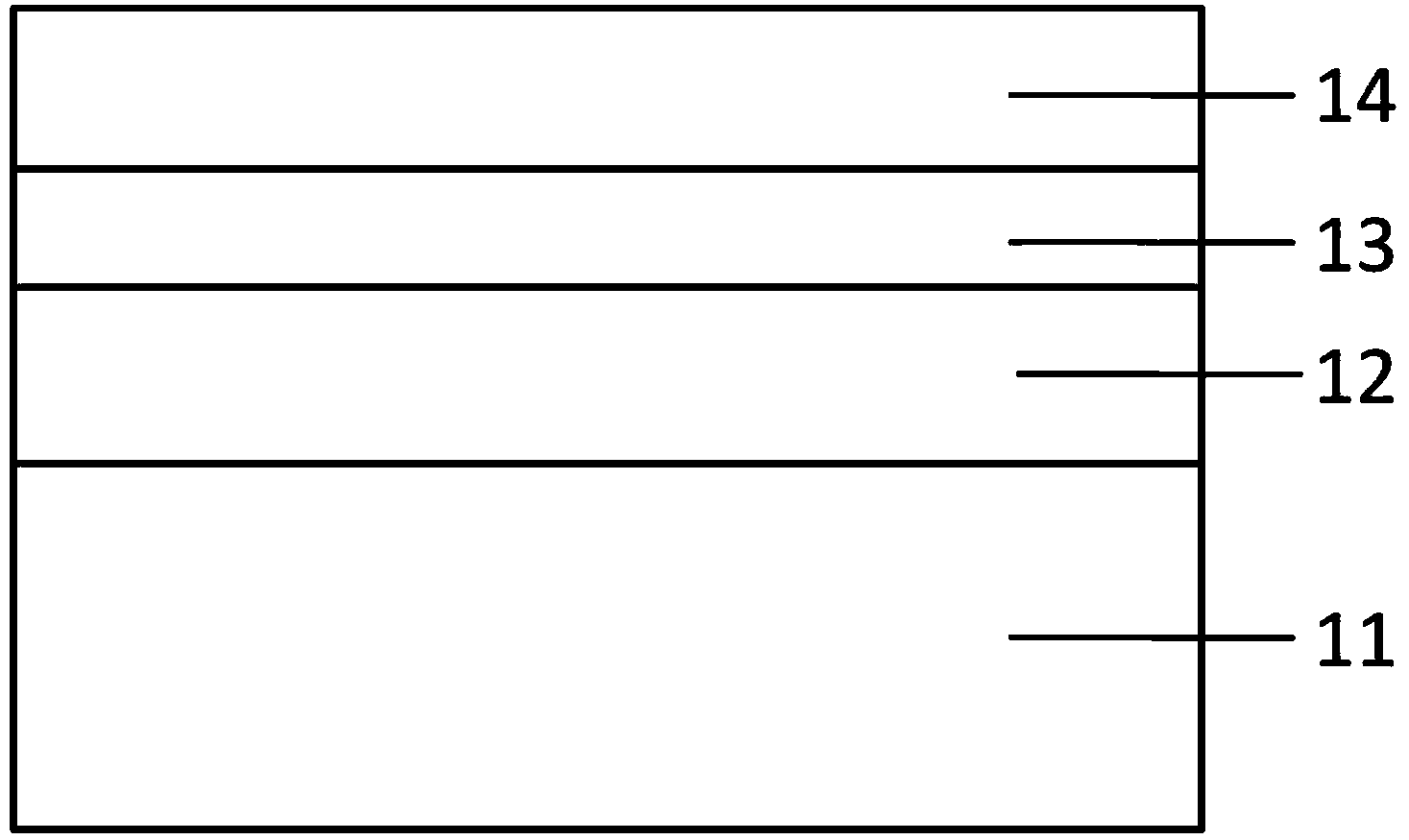

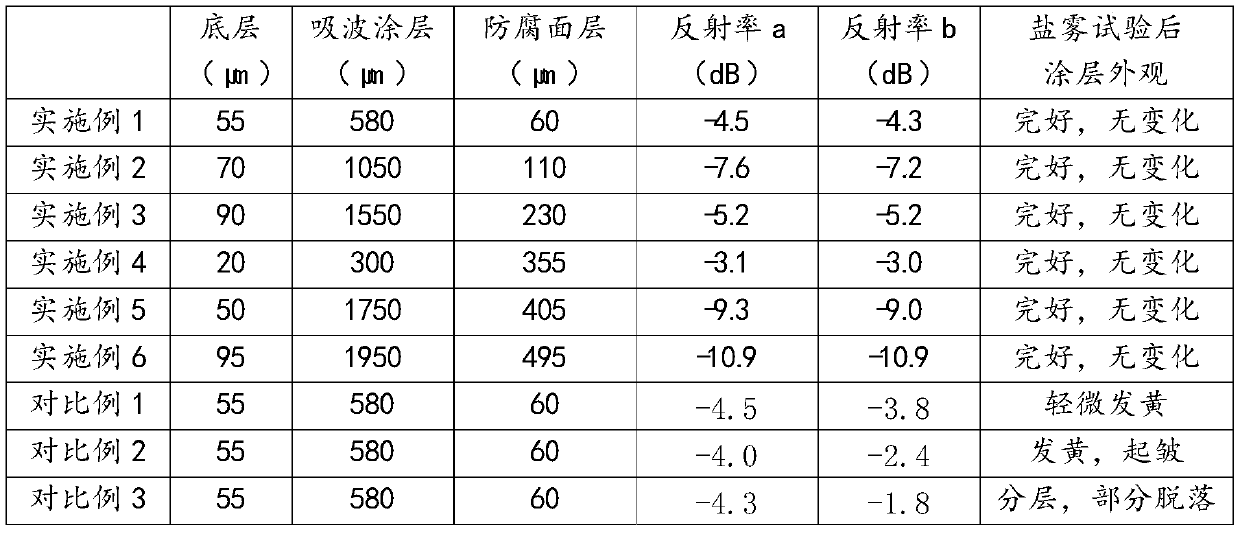

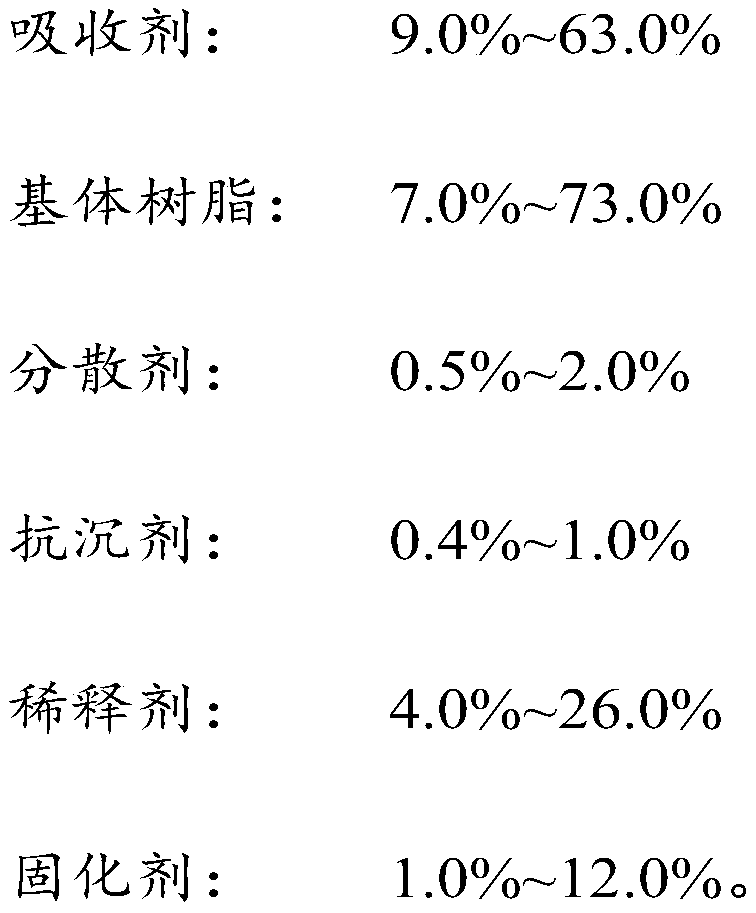

Anti-corrosion wave-absorbing coating and preparation method thereof

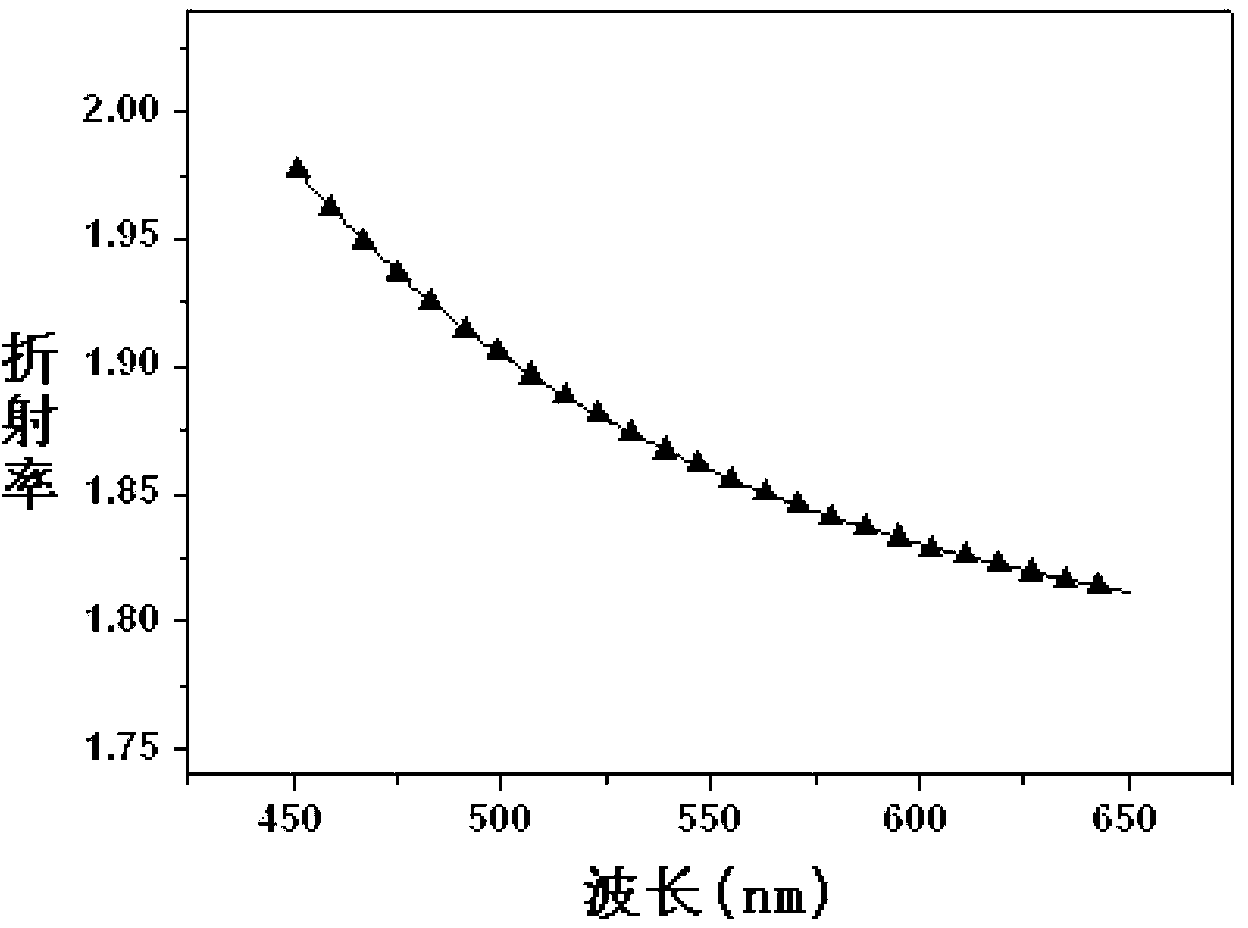

ActiveCN107892871AImprove compatibilityImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceSurface layer

The invention provides an anti-corrosion wave-absorbing coating and a preparation method thereof, and relates to the field of electromagnetic wave absorbing functional paint. The anti-corrosion wave-absorbing coating comprises an acrylic polyurethane bottom layer, a wave-absorbing layer and an anti-corrosion surface layer which are arranged sequentially, wherein the anti-corrosion surface layer isprepared by coating solvent-free polyurethane paint on the surface of the wave-absorbing layer. The preparation method of the anti-corrosion wave-absorbing coating comprises the following steps of: spraying acrylic polyurethane paint on the surface of a substrate to form the acrylic polyurethane bottom layer; spraying wave-absorbing paint on the cured acrylic polyurethane bottom layer to form thewave-absorbing layer; and spraying the solvent-free polyurethane paint to the surface of the cured wave-absorbing layer to form the anti-corrosion surface layer. The anti-corrosion wave-absorbing coating has the advantages of high wave-absorbing capability and excellent corrosion resistance, and can solve the problem of insufficient corrosion resistance of existing wave-absorbing coatings, and the weather resistance and service life of the wave-absorbing coating are improved.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

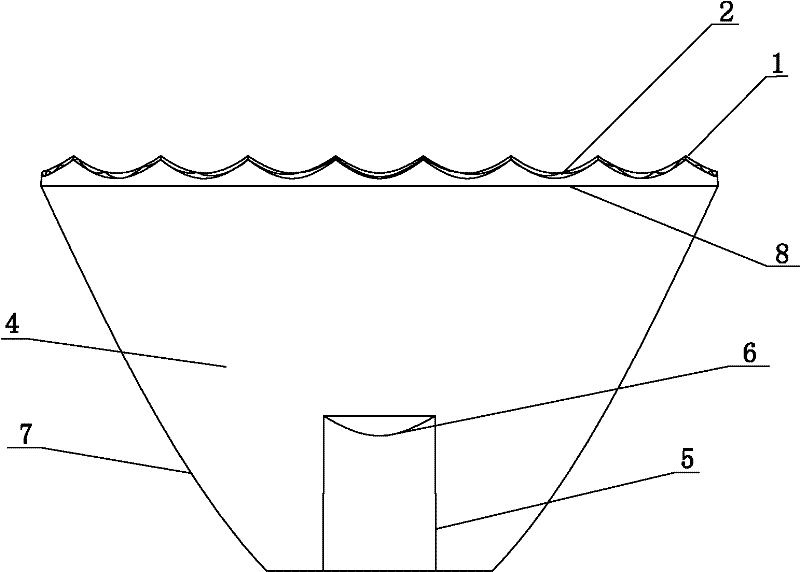

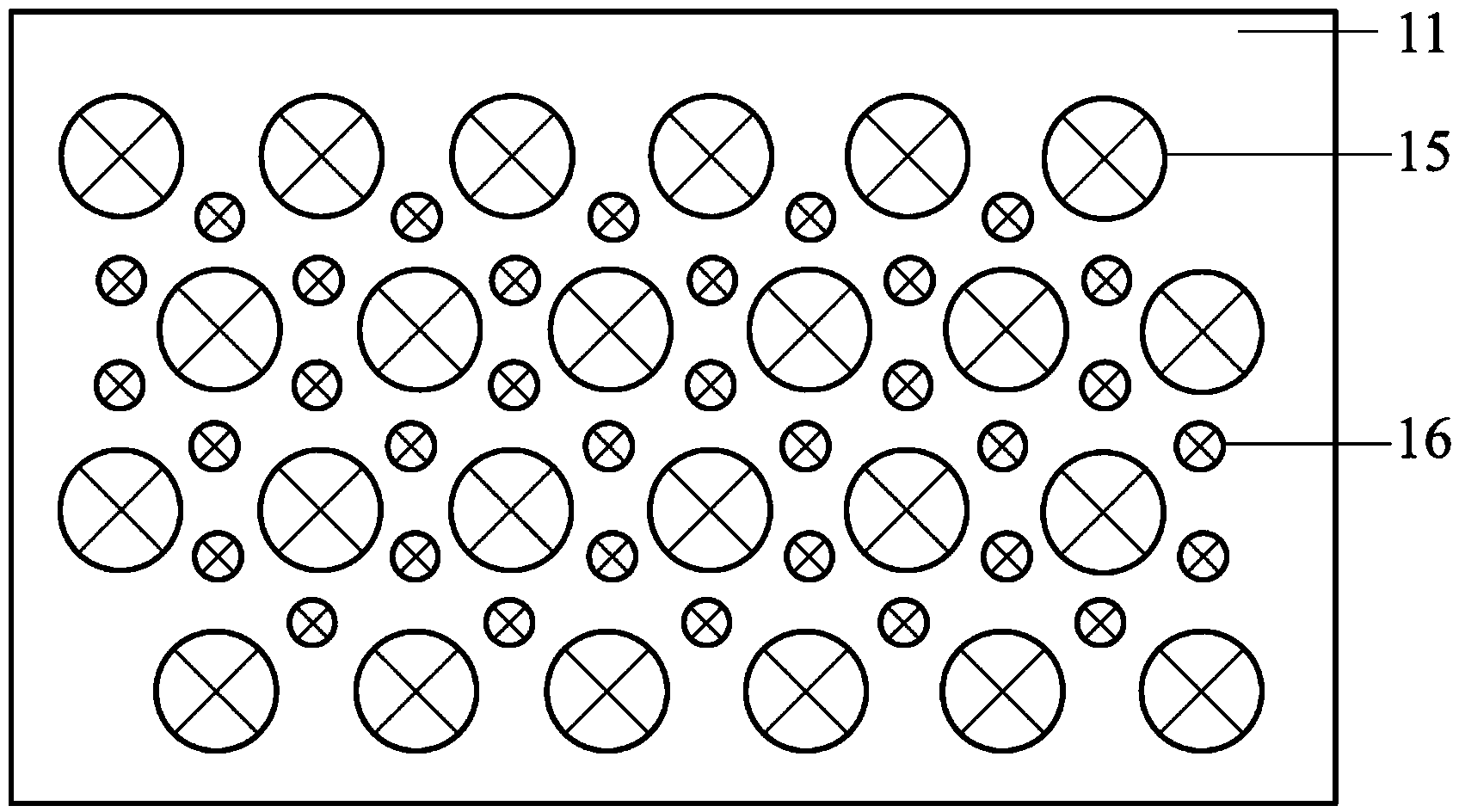

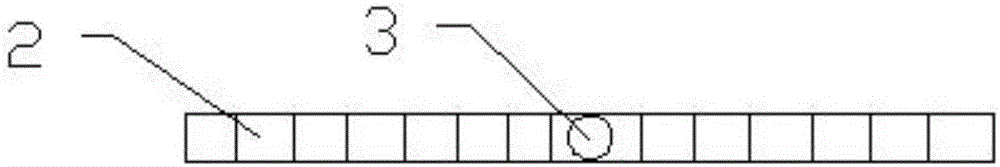

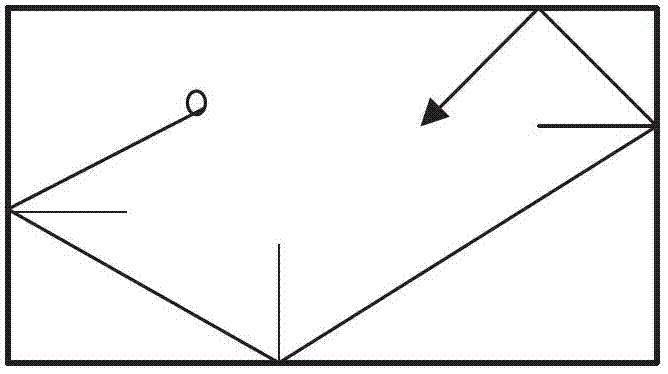

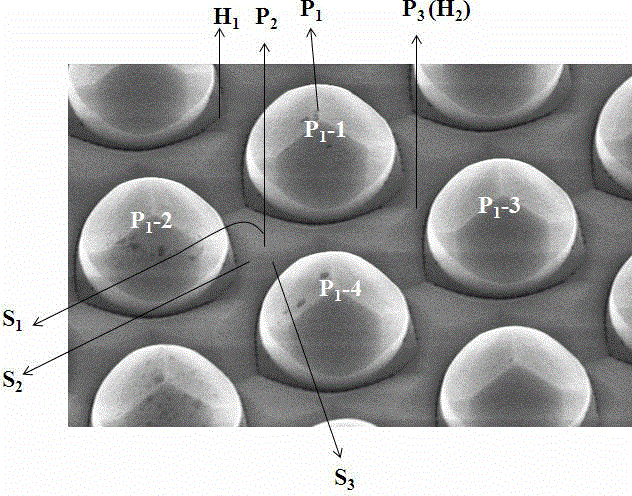

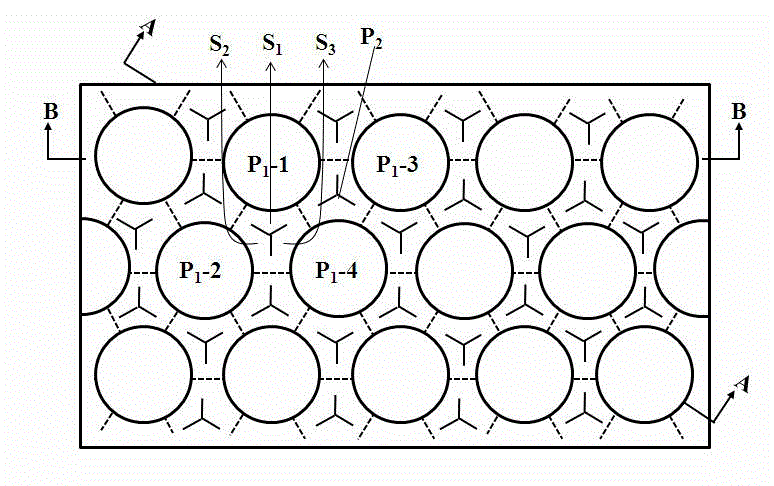

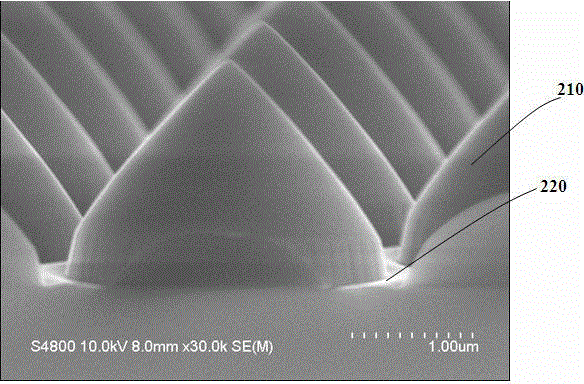

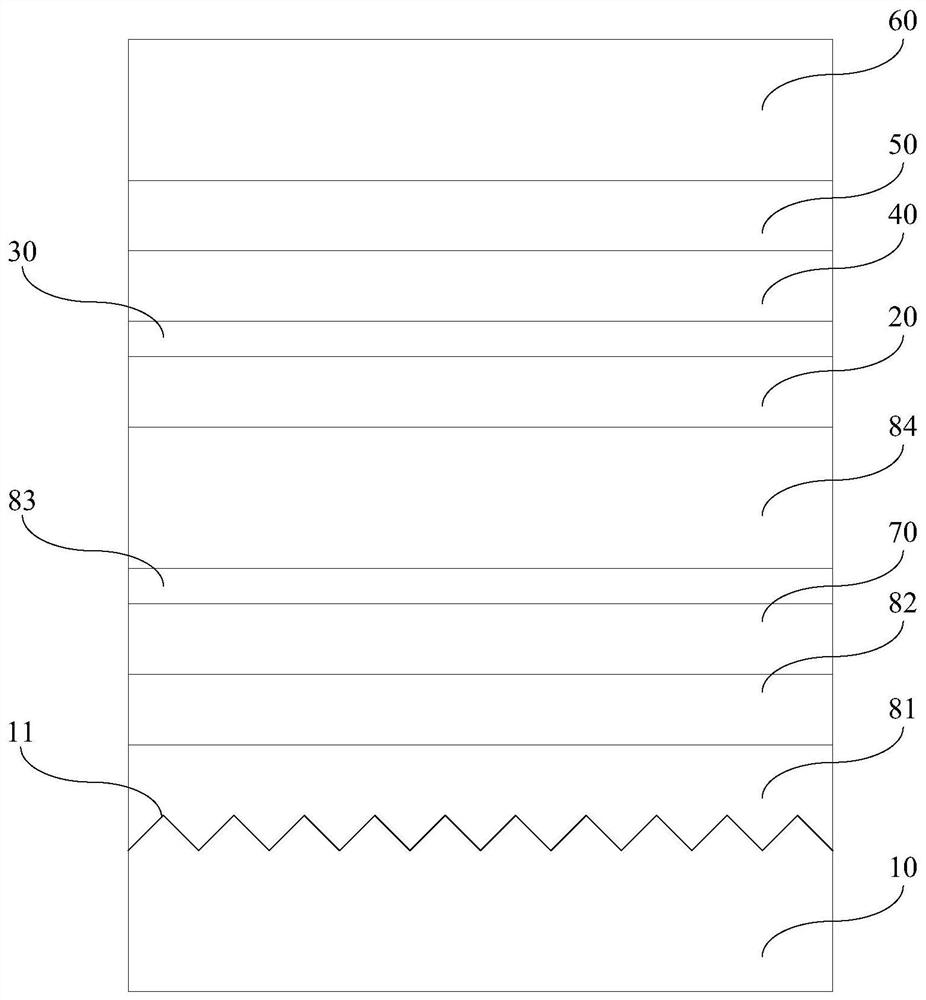

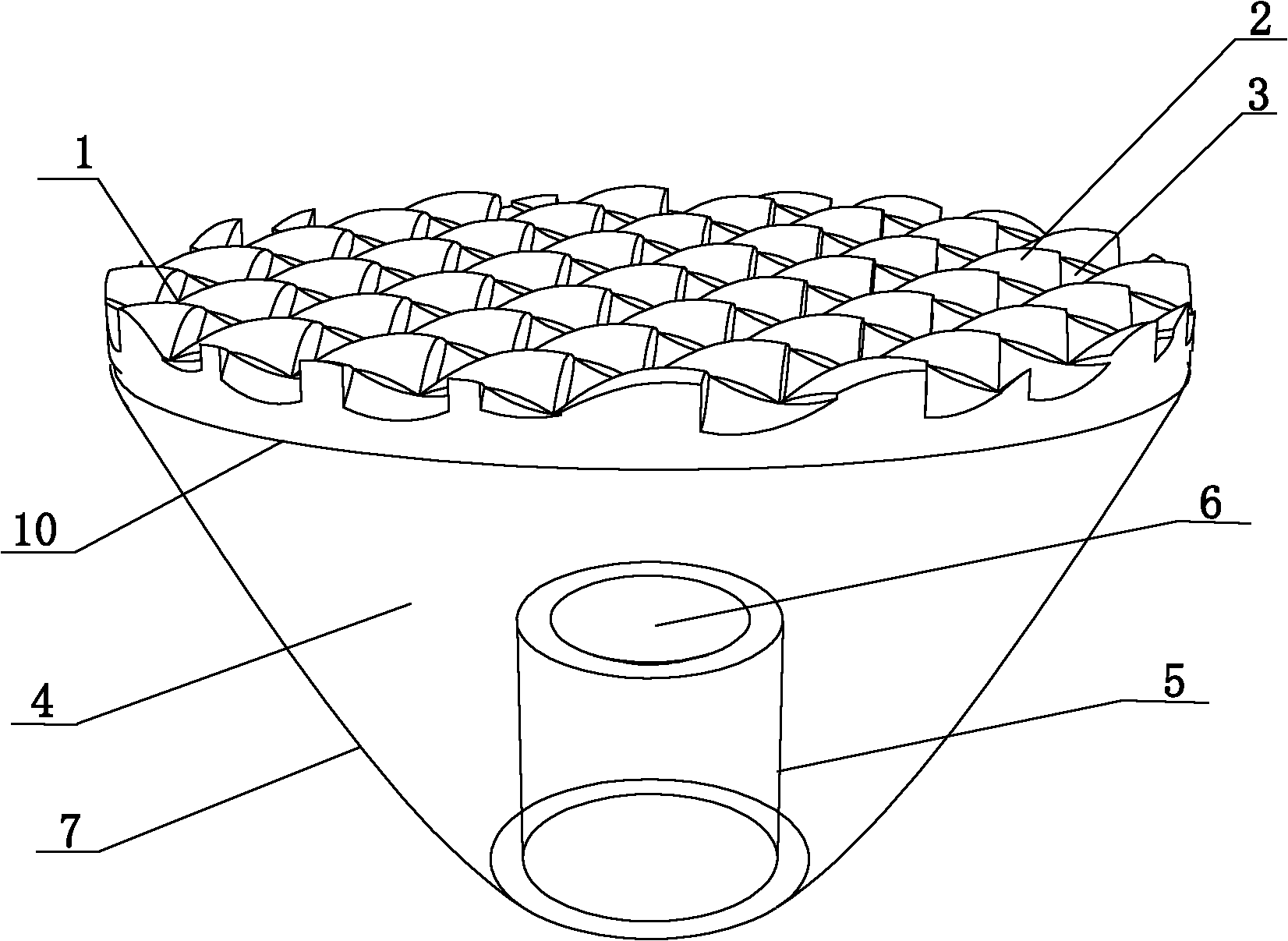

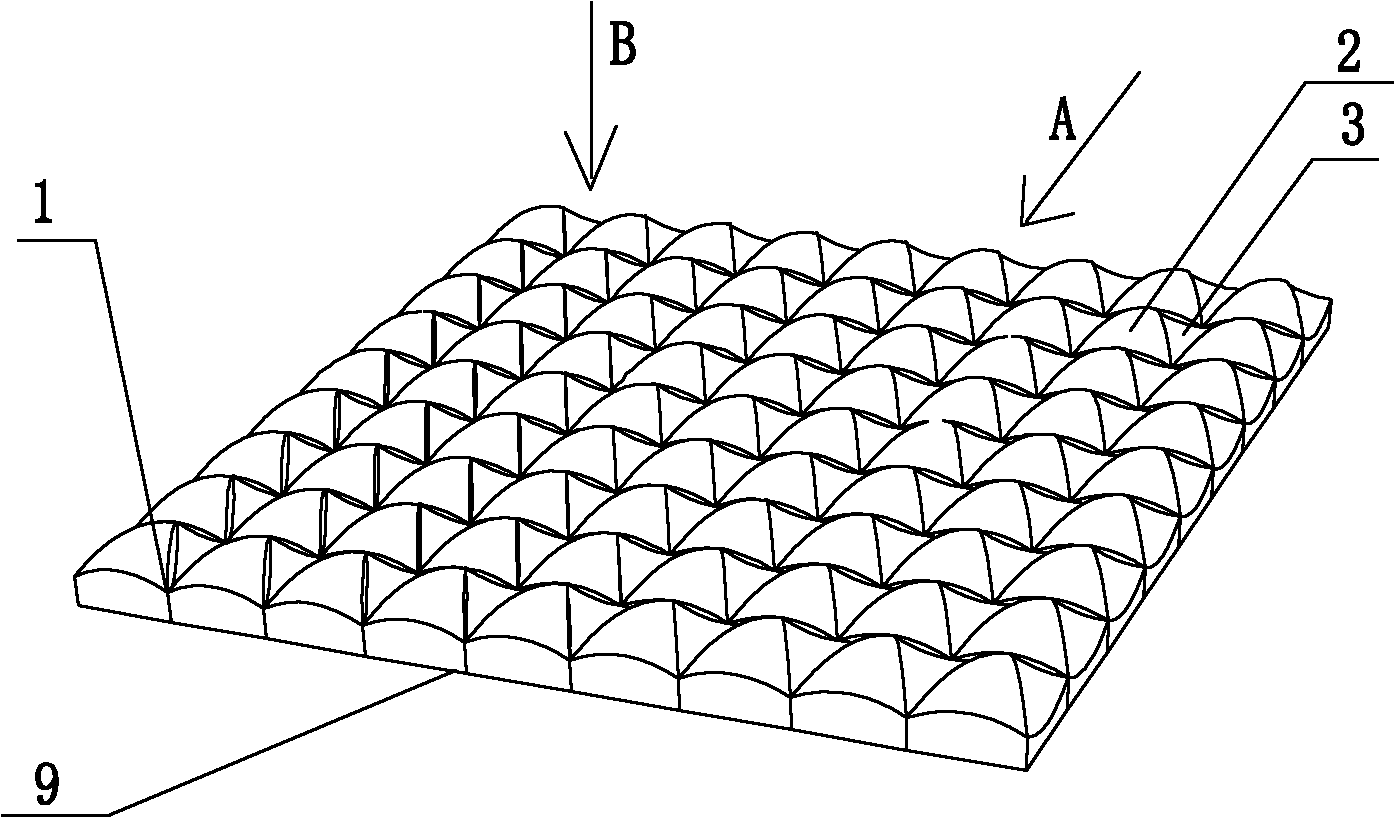

LED patterned substrate with main patterns and secondary patterns and LED chip

InactiveCN103545411AHigh extraction rateGood for injectionSemiconductor devicesEngineeringPatterned substrate

The invention discloses an LED patterned substrate with main patterns and secondary patterns. The patterns on the substrate are composed of the main patterns and the secondary patterns, and the main patterns and the secondary patterns are arranged on the surface of the substrate; the size of each secondary pattern is smaller than that of each main pattern; the secondary patterns are distributed in gaps between the main patterns. The invention further discloses an LED chip comprising the LED patterned substrate with the main patterns and the secondary patterns. Compared with a common LED patterned substrate, the LED patterned substrate with the main patterns and the secondary patterns has the advantages that the patterns on the substrate are denser, the LED chip emits more light beneficially, especially, the more light are emitted out of the top of the chip beneficially, the LED light extraction rate is increased greatly, and a new research and application direction is provided for patterned substrate technologies.

Owner:SOUTH CHINA UNIV OF TECH

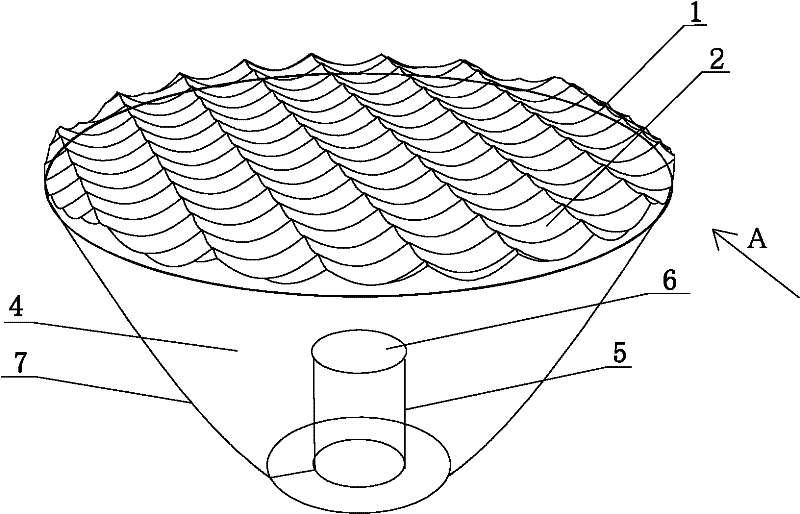

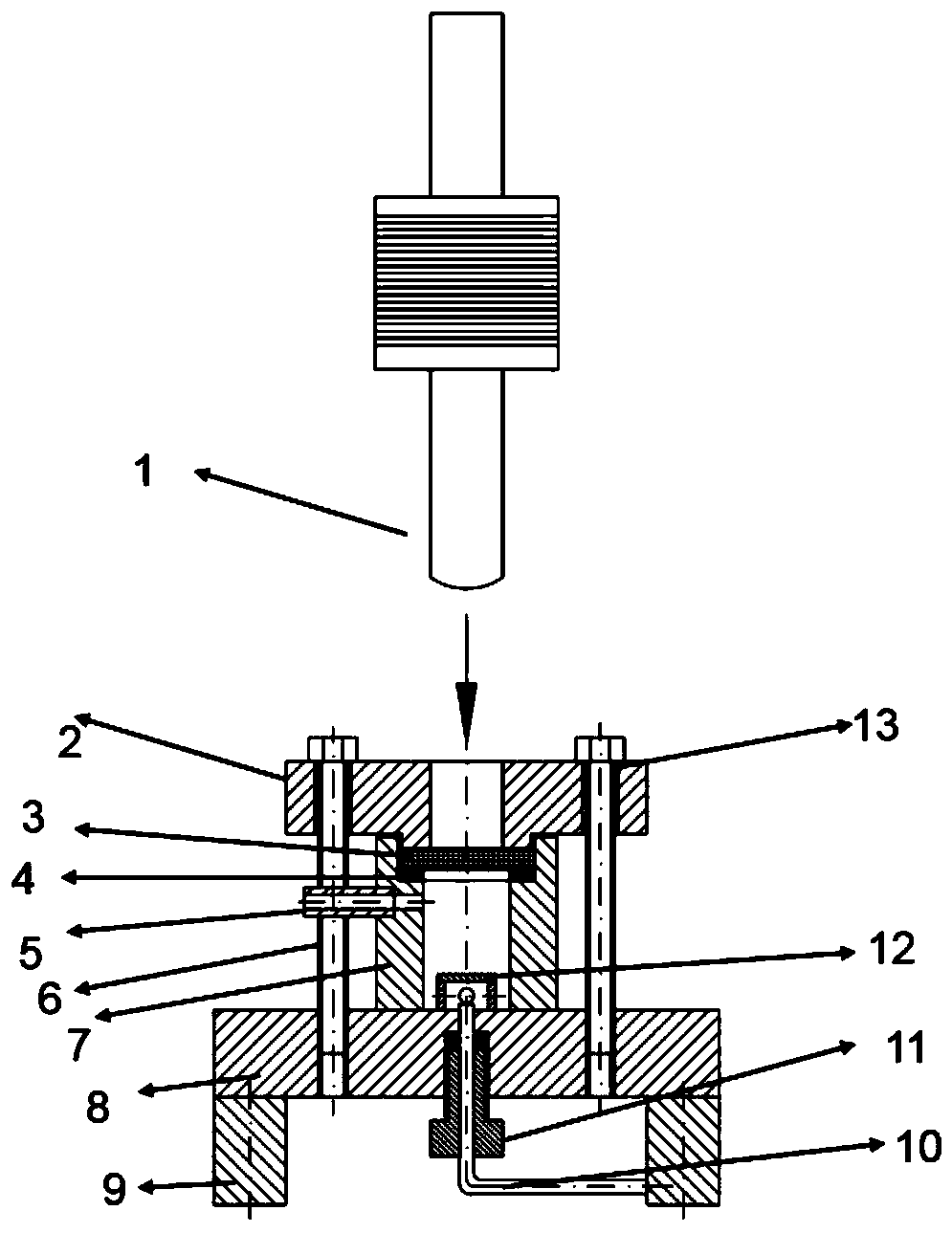

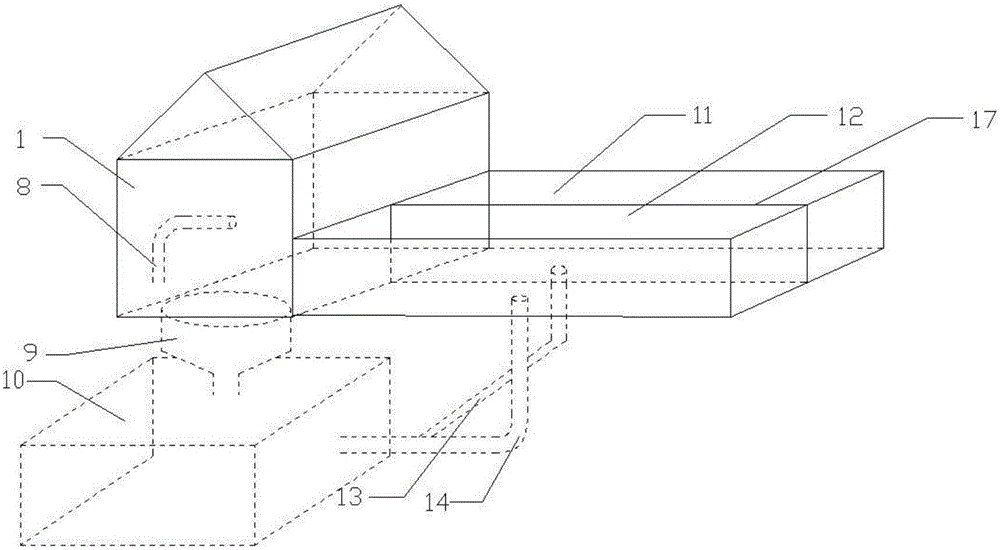

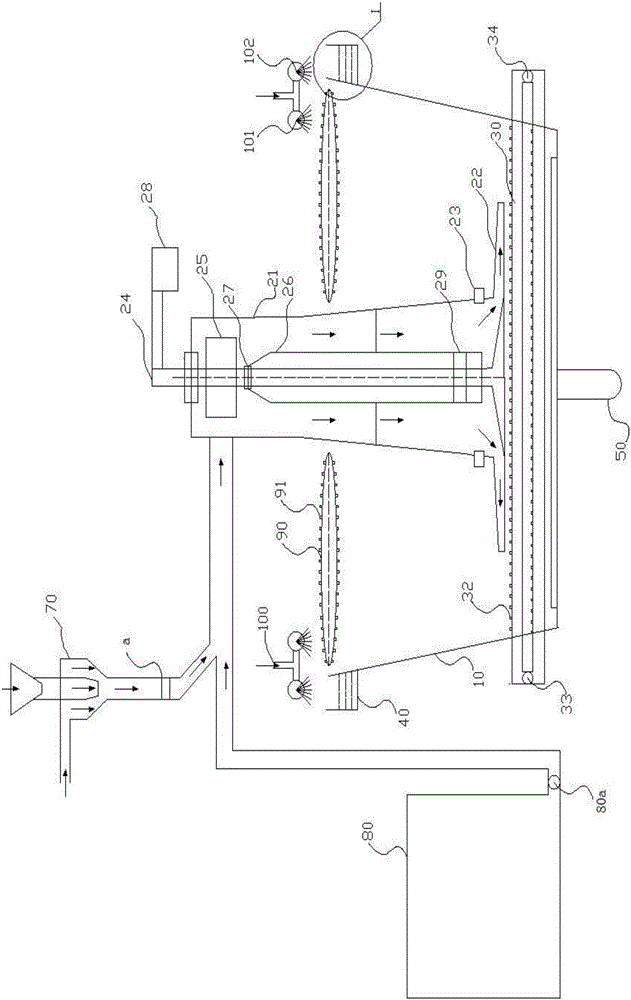

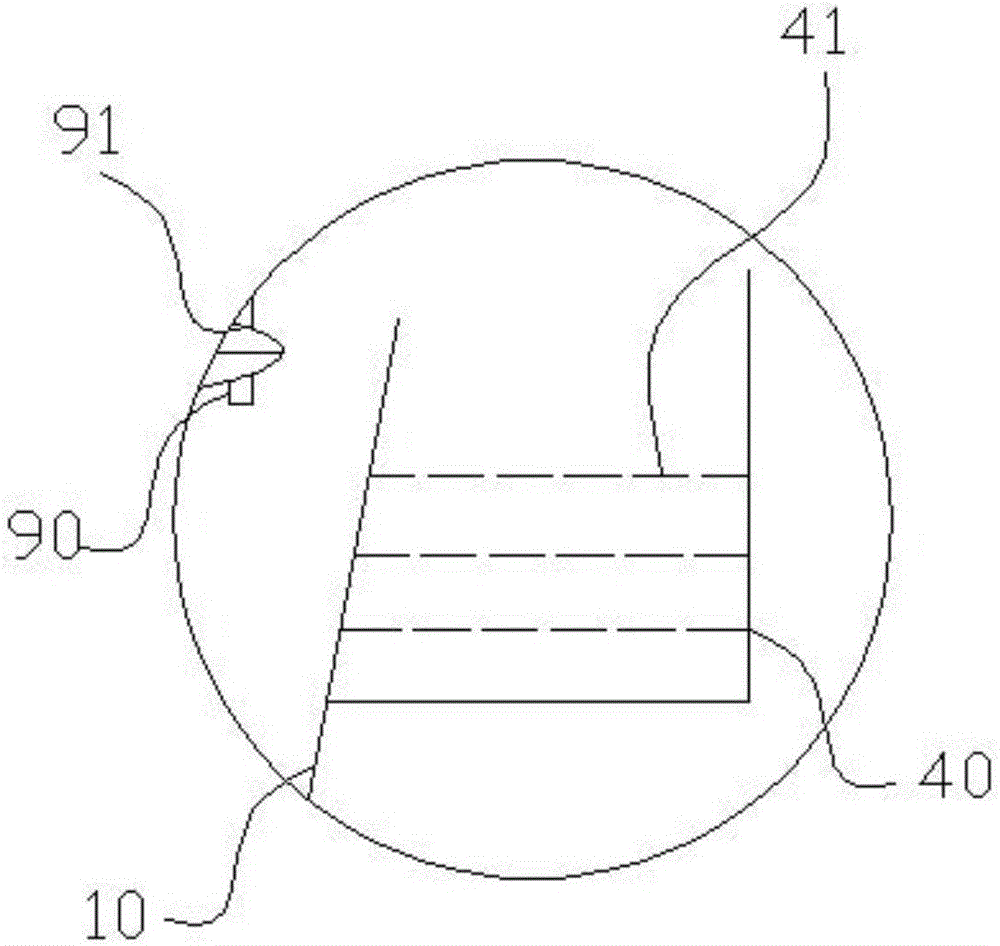

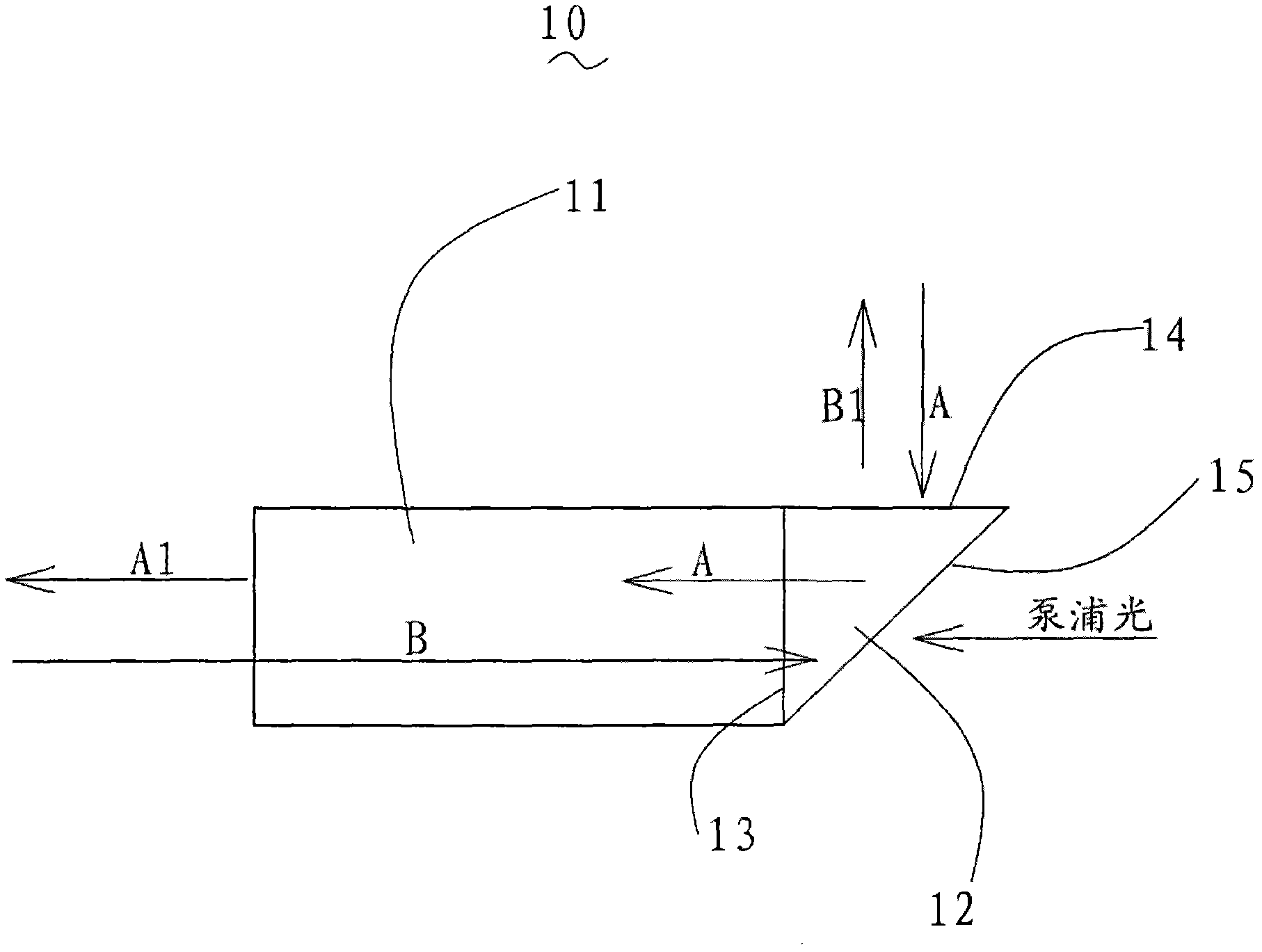

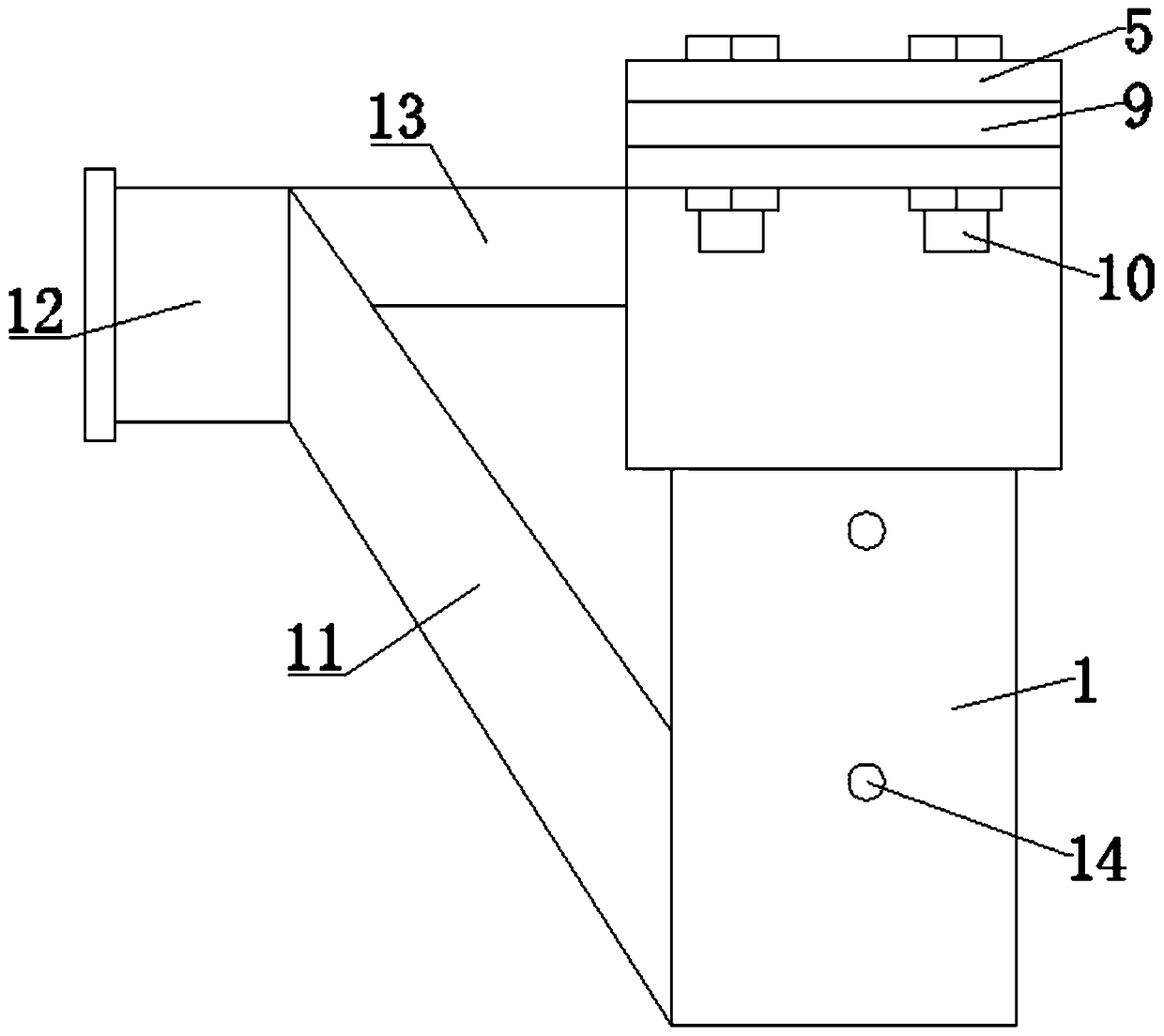

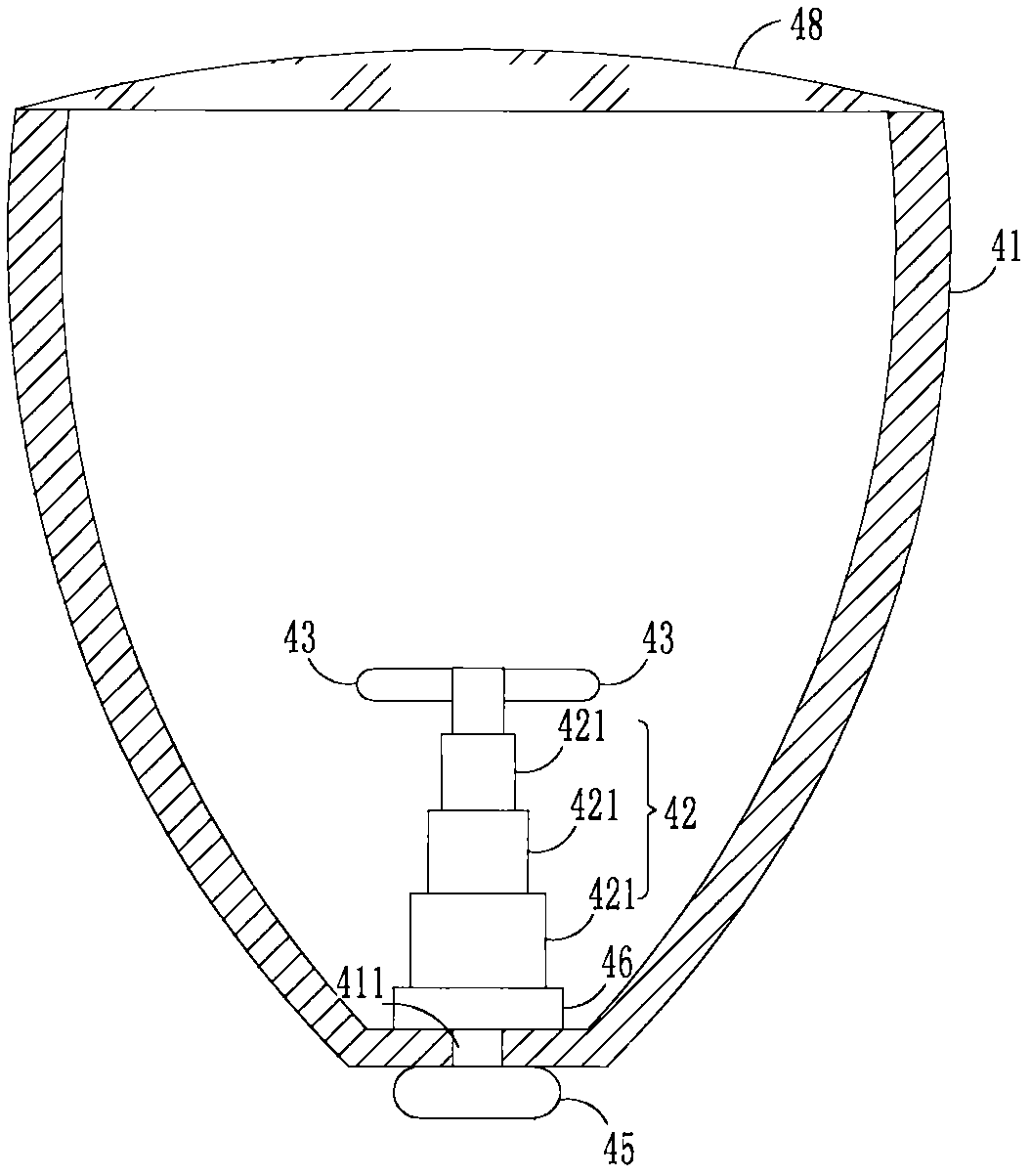

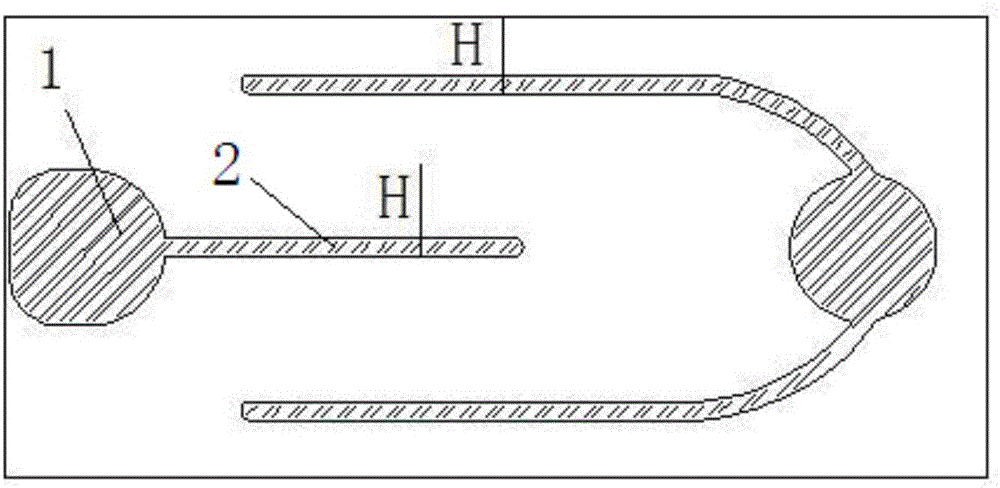

Photothermal-coupled microchannel hydrogen-producing reaction device based on high-concentration point light source

The invention discloses a photothermal-coupled microchannel hydrogen-producing reaction device based on a high-concentration point light source. The device includes the high-concentration point lightsource and the like. During operation of the device, the direction of the high-concentration point light source is vertically downward; a catalyst placing table is placed on the center of the bottom of a reaction chamber and is aligned with the light path of the high-concentration point light source; a catalyst is placed on the catalyst placing table; reactants are added into the reaction chamber;before a reaction, the reaction chamber is purged with an inert gas by using a gas purging channel, then the high-concentration point light source is used for focusing light of different wavelength bands onto the surface of the photothermal catalyst; and after the reaction, a product is collected via a product sampling port and detected. The reaction device of the invention has a small size and is small in the size of each channel, so the point light source can conveniently focus light onto a catalyst carrier, energy flow density is greatly improved, and at the same time, the gathering of strong light carries heat so as to achieve the purpose of producing hydrogen via a photothermal coupled reaction. The photothermal-coupled microchannel hydrogen-producing reaction device of the inventionhas the advantages of simple structure, convenient operation, stable operation, good heat transfer effect, etc.

Owner:XI AN JIAOTONG UNIV

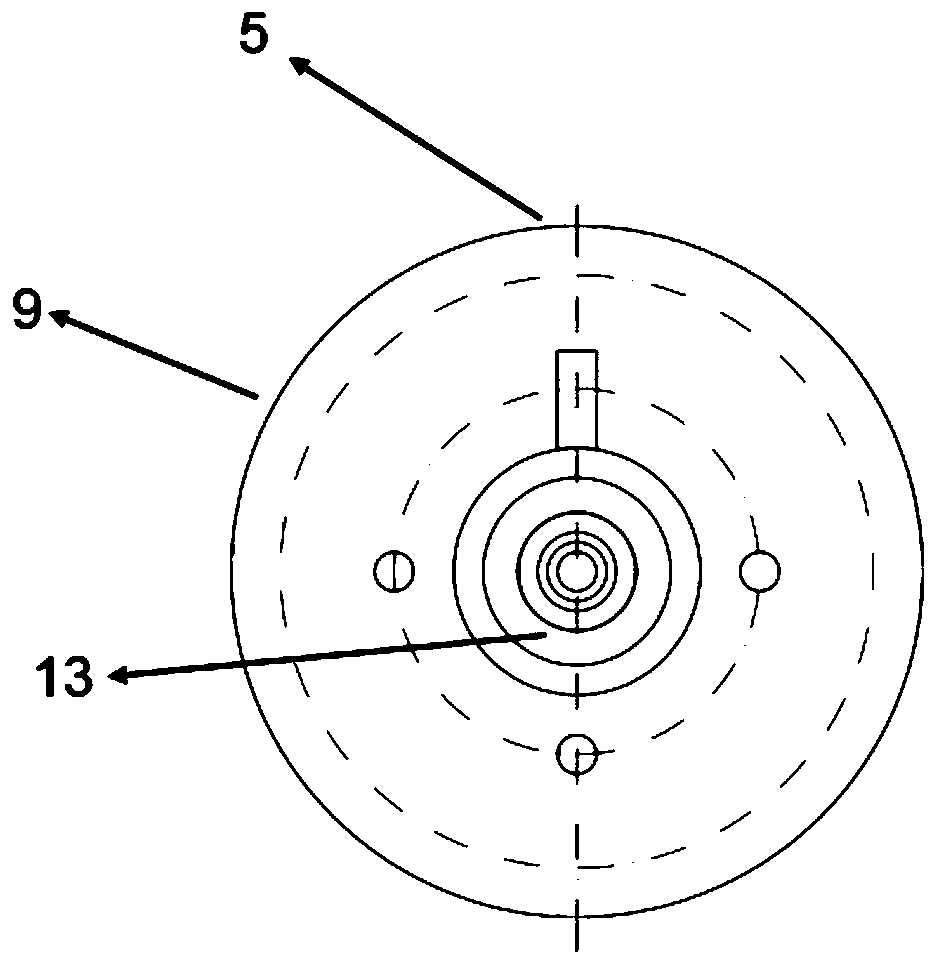

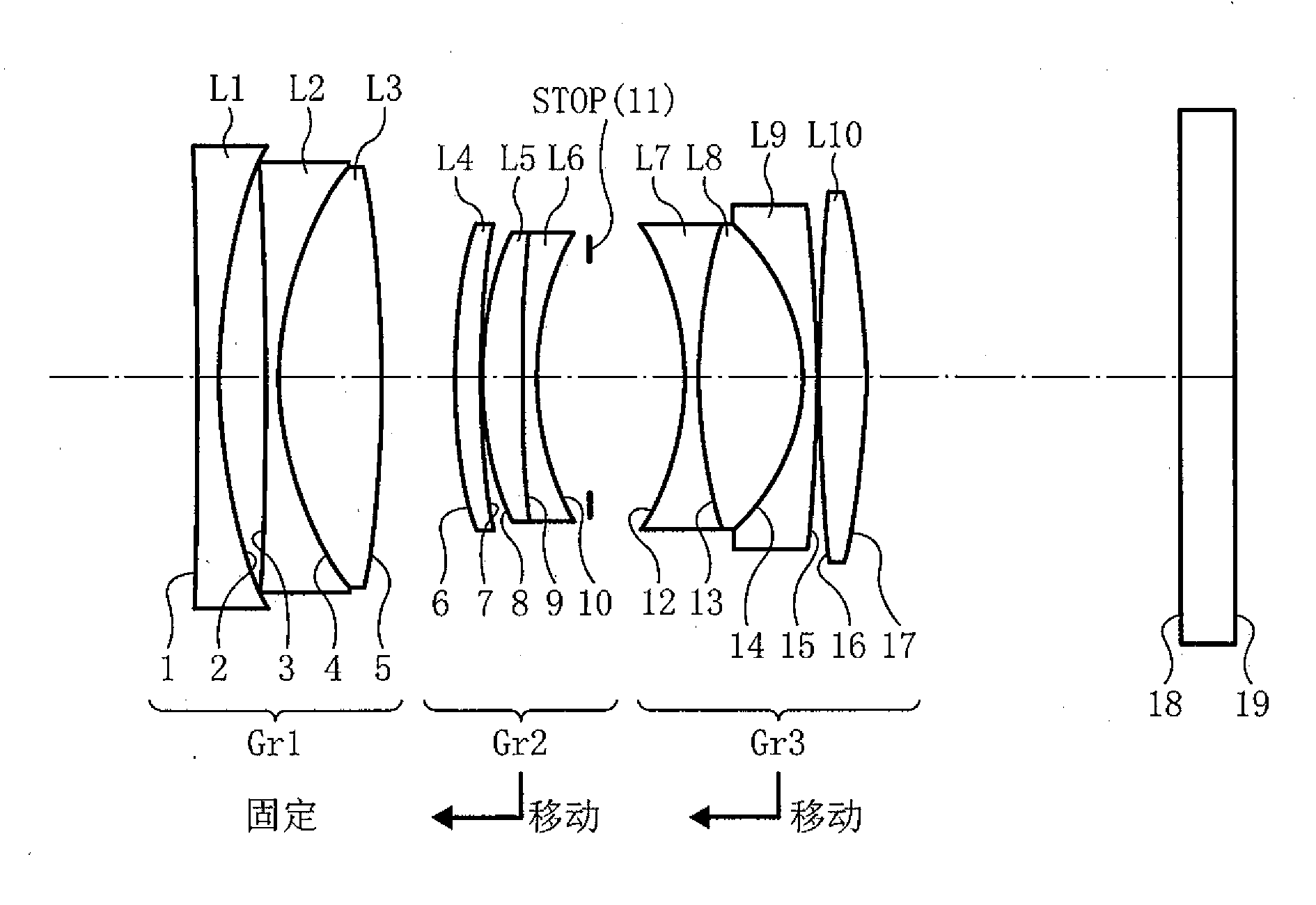

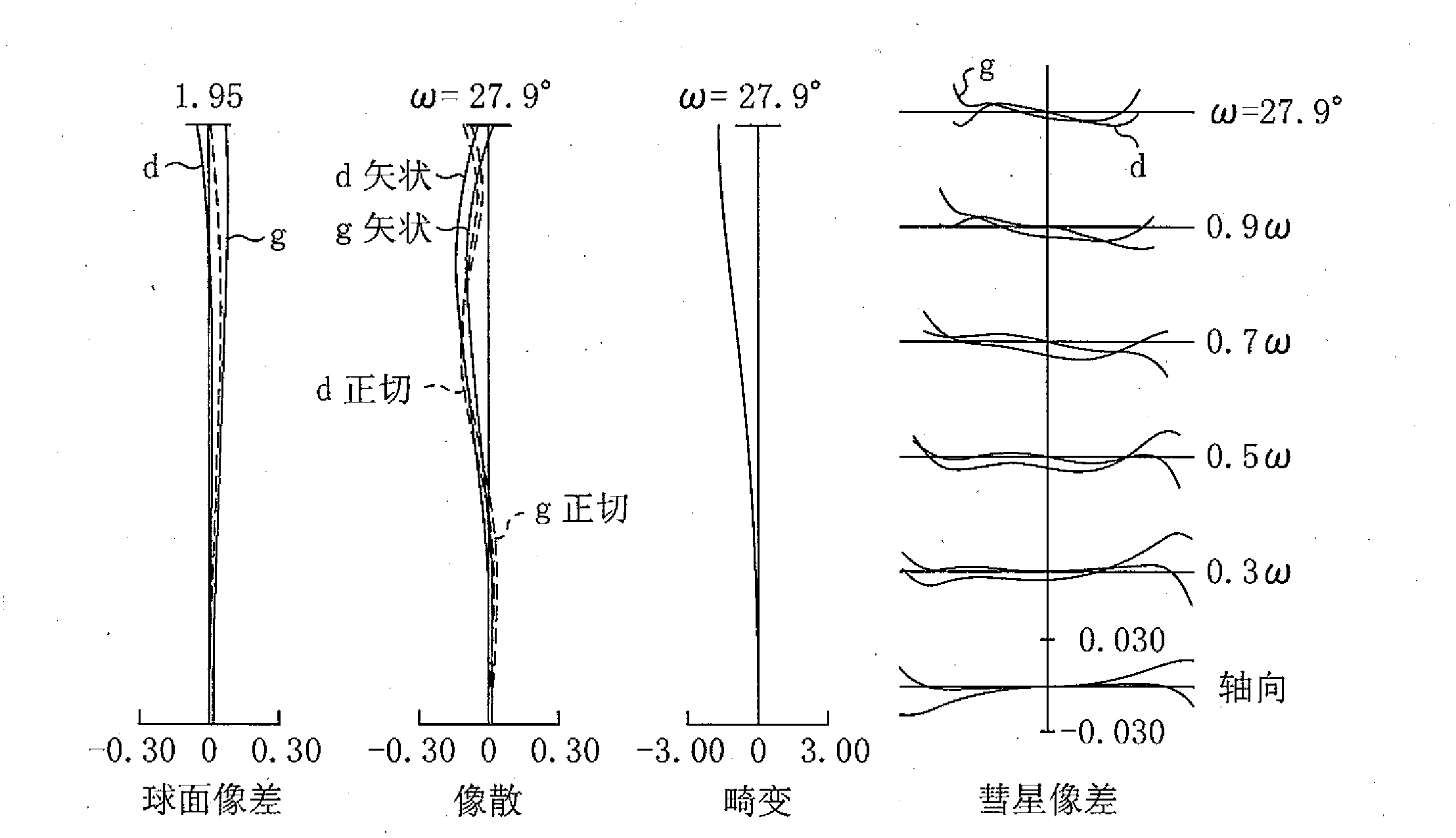

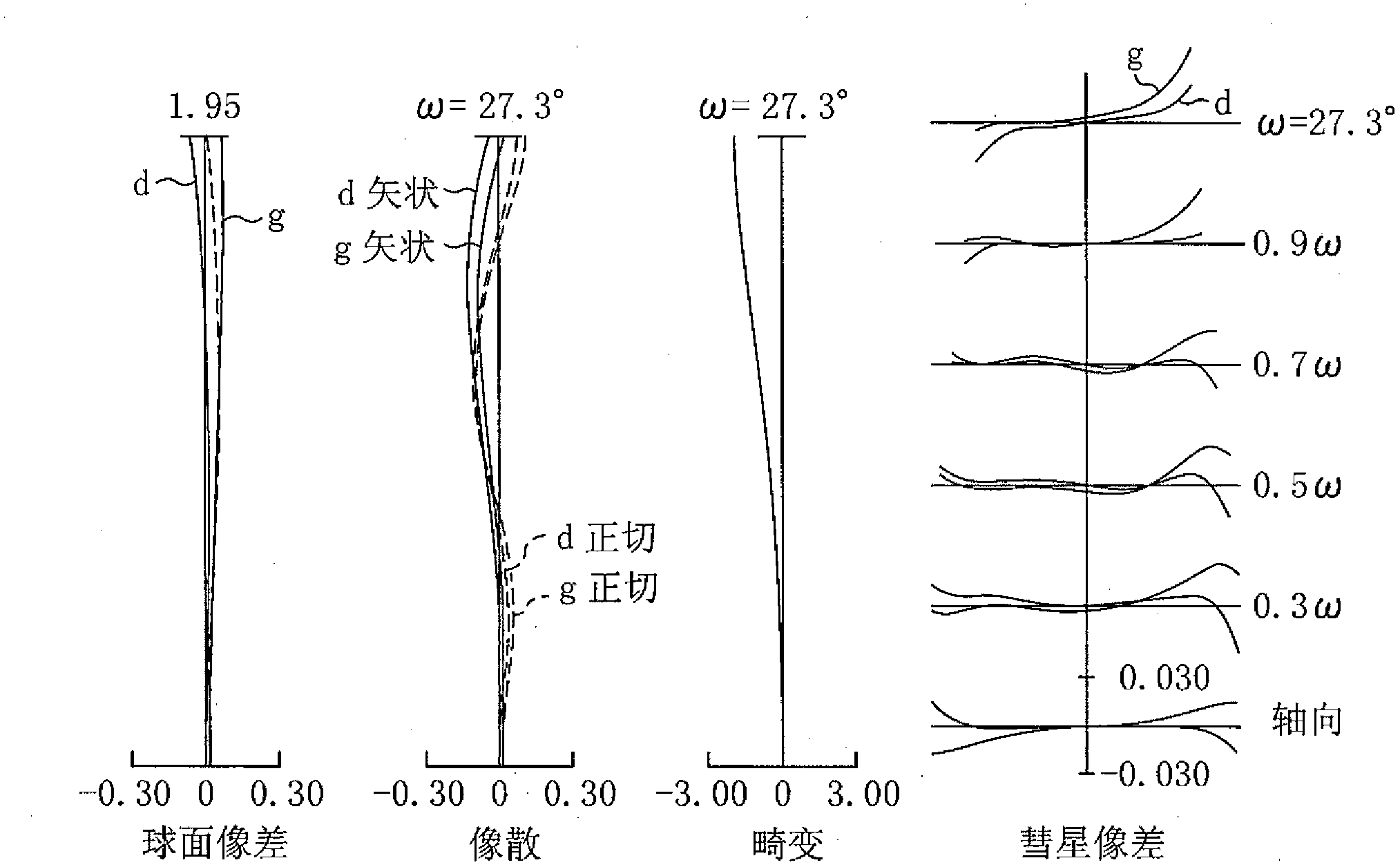

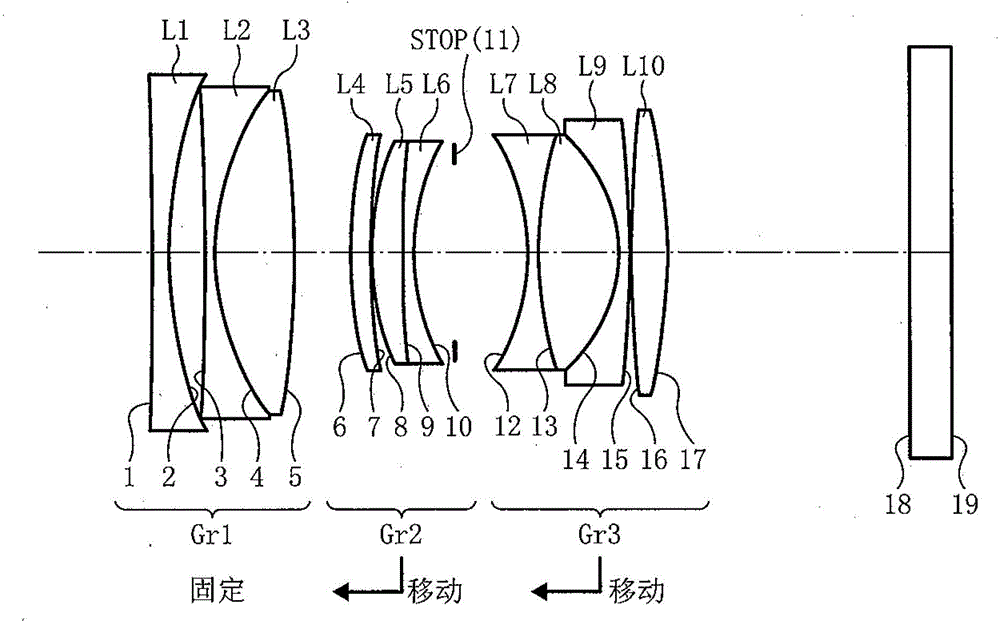

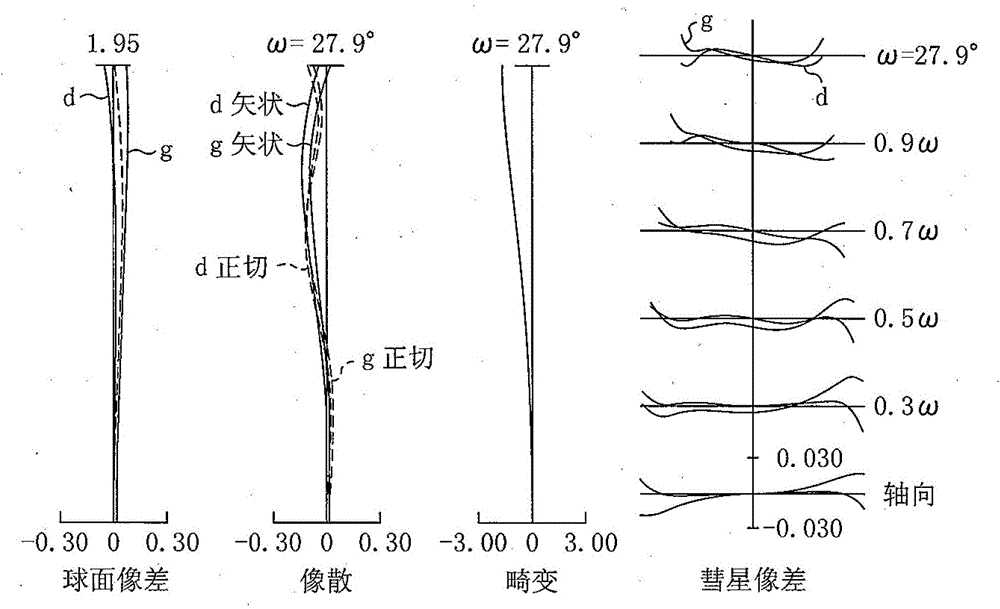

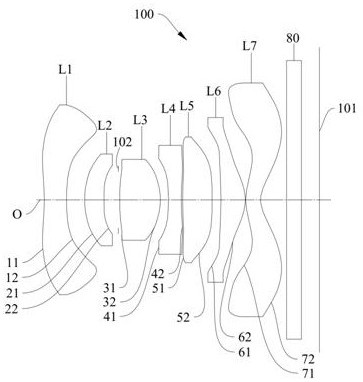

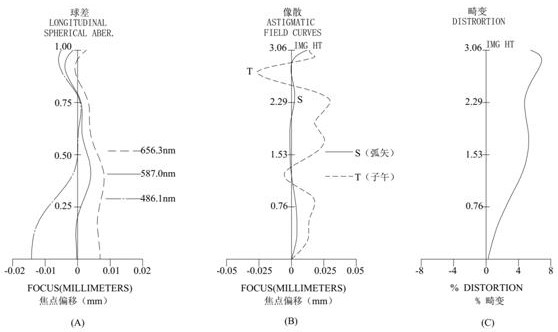

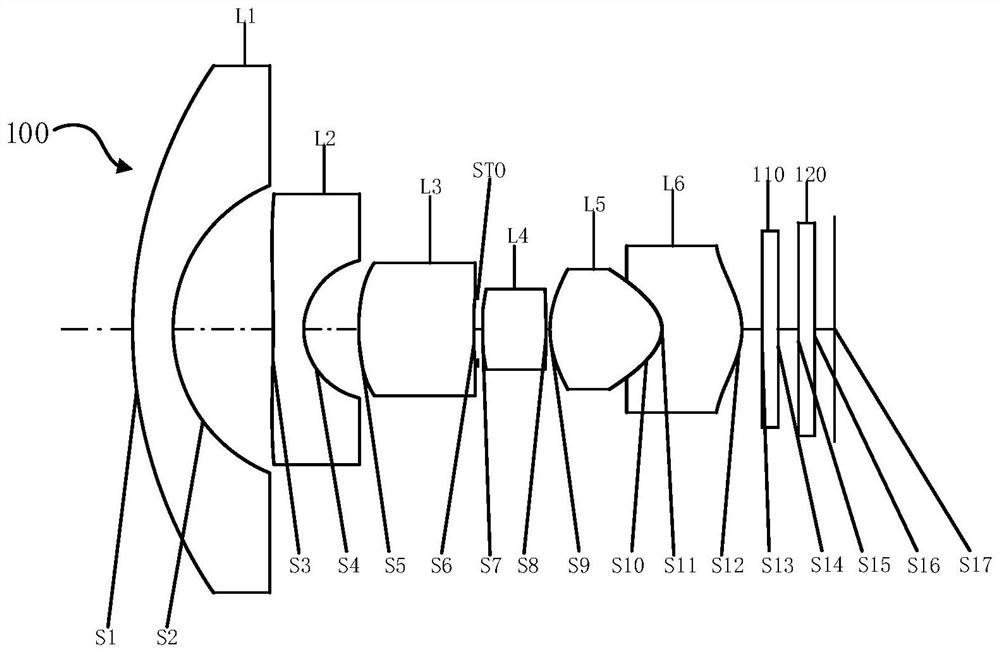

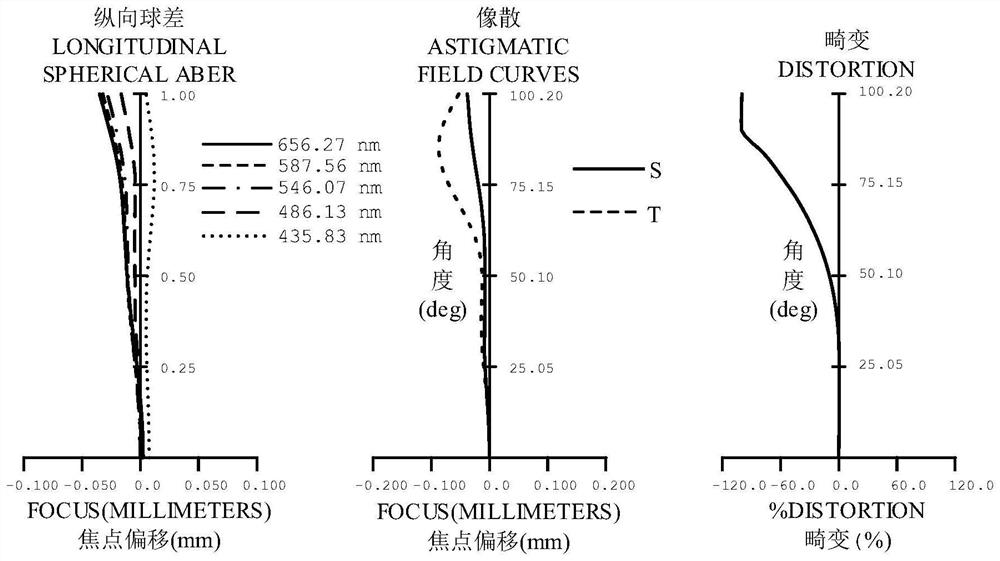

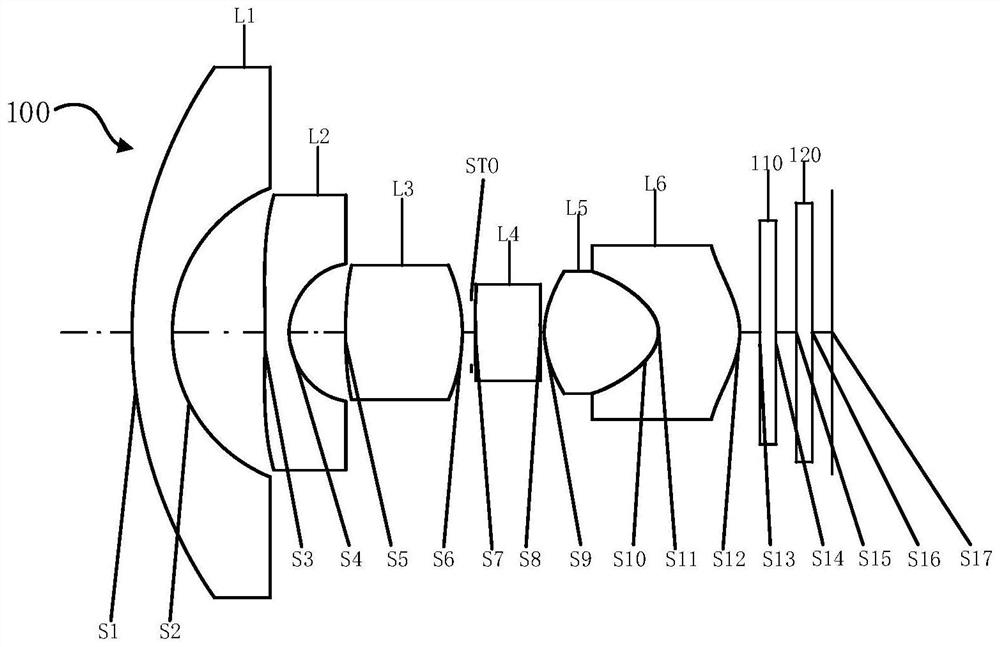

Imaging lens, camera device and portable information terminal device

ActiveCN102841433AShorten the lengthSignificant differenceOptical elementsNegative refractionCamera lens

The invention relates to an imaging lens, a camera device and a portable information terminal device, which can be used to provide an emitting-out pupil far away from the image surface, and is provided with a large-caliber small-sized high performance fixing imaging lens. The imaging lens is provided, from object side to image side, a first lens group (GR1) having the positive refraction ability or the negative refraction ability, a second lens group (GR2) having the positive refraction ability, and a third lens group (GR3) having the positive refraction ability. An aperture (Stop) is disposed between the second lens group and the image surface. The focusing can be realized by fixing the first lens group and moving the second lens group and the third lens group along the optical axis, and the condition can be satisfied, the F2 / F3 is less than 1.6 and larger than 0.5, the IFI / F is less than 20.0 and larger than 6.0, wherein the F is the focal length of the whole system of the imaging device by the infinity sharp focus, the F1, the F2, and the F3 are respectively the focal lengths of the first length group, the second length group, and the third length group.

Owner:RICOH KK

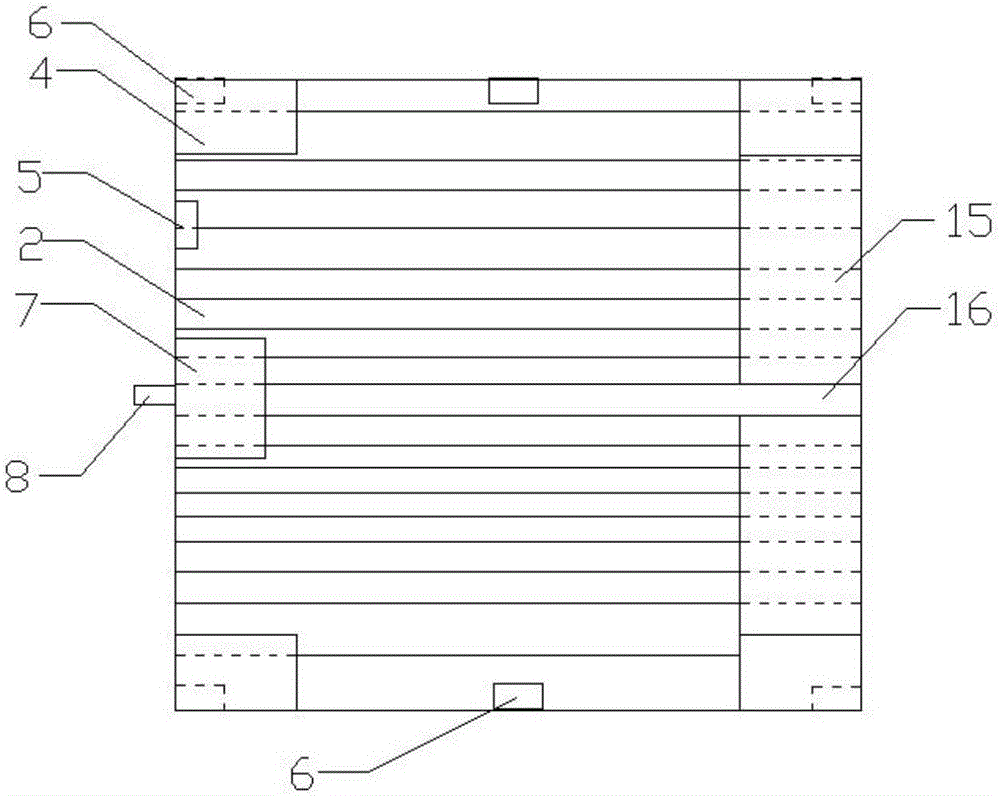

Goat rearing system

InactiveCN106577318AGuaranteed cleanlinessIncrease temperatureMethane captureWaste based fuelFecesEngineering

The invention discloses a goat rearing system and belongs to the technical field of goat cultivation. The system comprises a goat house, a feeding module, a pollution discharge module and a stocking module. The goat house comprises four walls, a roof and a leak goat bed; a rotary shaft is arranged on the middle portion of the goat bed, and the rotary shaft can be driven by a motor to drive the goat bed to overturn, so that feces of goats fall into the pollution discharge module; the pollution discharge module comprises a manure pit, a biogas digester, a dung scraper and a cleaner; the manure pit is arranged below the goat bed and communicates with the biogas digester through a pipeline; the dung scraper is arranged on the goat bed, and the cleaner is arranged on the four walls of the goat house and is close the goat bed; the stocking module comprises a stocking portion and a planting portion isolated by a fence, and the stocking portion and the planting portion are separately provided with pipelines communicating the biogas digester. The goat rearing system can be used for immediately cleaning feces of goats, comprehensively utilizing feces of the goats and maintaining the goat house clean.

Owner:连云港市赣榆区班庄镇农业技术服务中心

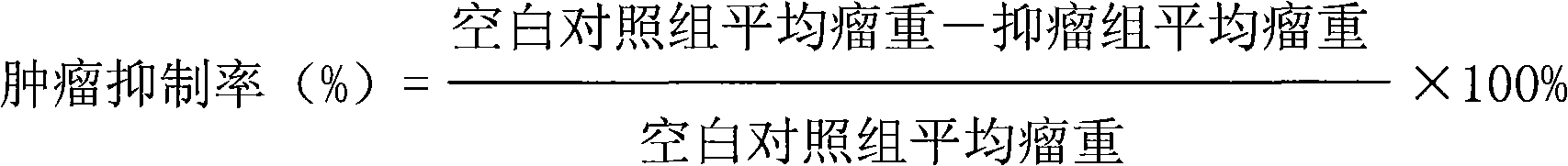

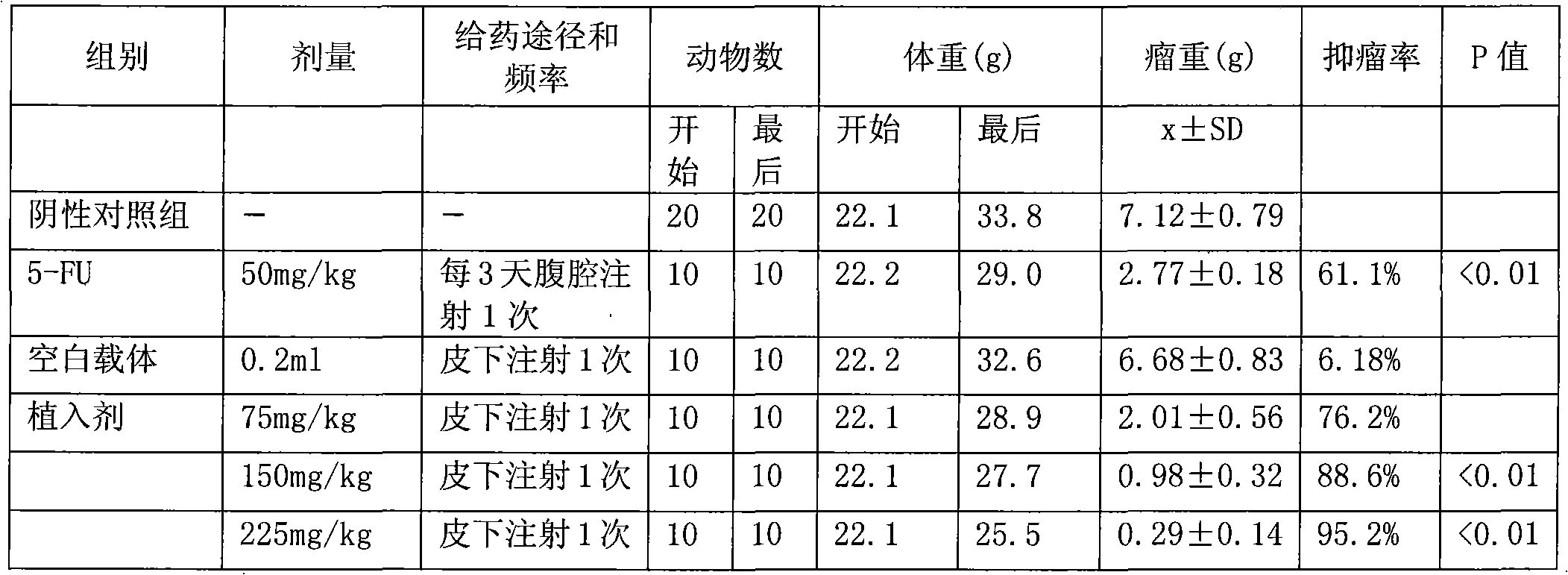

2-methoxy estradiol injectable hydrogel implant

InactiveCN101953774AEffectively maintain the effective concentration of the target siteFormulation ScienceOrganic active ingredientsPharmaceutical delivery mechanismMedicineTherapeutic effect

The invention relates to a 2-methoxy estradiol injectable hydrogel implant which can effectively solve the problems of maintaining the effective concentration of the target part of 2-methoxy estradiol and enhancing the treatment effect. The invention has the technical scheme that a temperature sensitive type PLGA-PEG-PLGA segmented copolymer having temperature sensitive hydrogel properties is adopted to be mixed with water to prepare dissolution swelling solution; the solution is mixed with the 2-methoxy estradiol to prepare an injection; the temperature sensitive type PLGA-PEG-PLGA segmented copolymer is uniformly mixed with the water to be kept stewing at 0 to 25 DEG C; the temperature sensitive type PLGA-PEG-PLGA segmented copolymer is fully dissolved and swelled into the solution; and the 2-methoxy estradiol is added to be uniformly mixed with solution at 0 to 25 DEG C on the use day or one day before use. The invention has scientific formula, easy production, low cost and good injection effect, can effectively maintain the effective concentration of the target part of the 2-methoxy estradiol and enhance the treatment effect is enhanced and is the innovation on the path of cancer treatment drug forms and drug administration.

Owner:ZHENGZHOU UNIV

Light emitting diode and manufacturing method thereof

ActiveCN103715319AReduce total reflection absorptionIncrease brightnessSemiconductor devicesQuantum wellLight-emitting diode

The invention provides a light emitting diode and a manufacturing method thereof. The method comprises the following steps: preparing a selective growth layer on a surface of a substrate first; then, selectively growing a light emitting structure layer in an epitaxial mode in a non-selective growth layer region of the surface of the substrate, wherein the light emitting structure layer is of an inverted trapezoidal structure and at least includes an N-type semiconductor layer, a quantum well layer and a P-type semiconductor layer; etching to an N electrode region with the use of the photo-etching technology, the ICP technology or the RIE technology; making a transparent conductive layer; making a P electrode and an N electrode; preparing a first reflective mirror layer on the transparent conductive layer and preparing a second reflective mirror layer on the other surface of the substrate; and finally, carrying out splintering to complete preparation of the independent light emitting diode. According to the light emitting diode prepared by using the epitaxial selective growth technology, total reflection absorption of a chip to light can be reduced, light can be emitted out from the inside of the light emitting diode, the light extraction efficiency of light on the side wall of the chip is improved, and the excitation efficiency of fluorescent powder is improved and the brightness of the chip is improved due to the adoption of two-way reflective mirrors.

Owner:EPILIGHT TECH

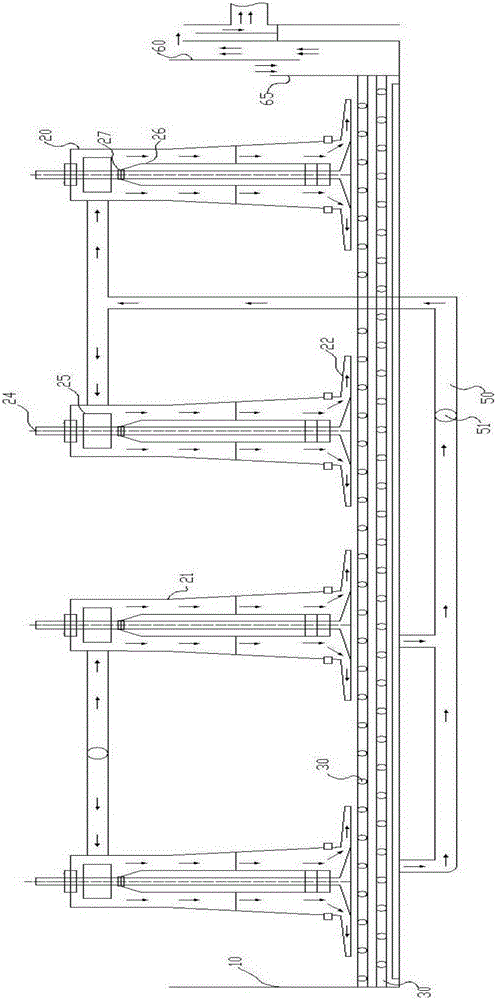

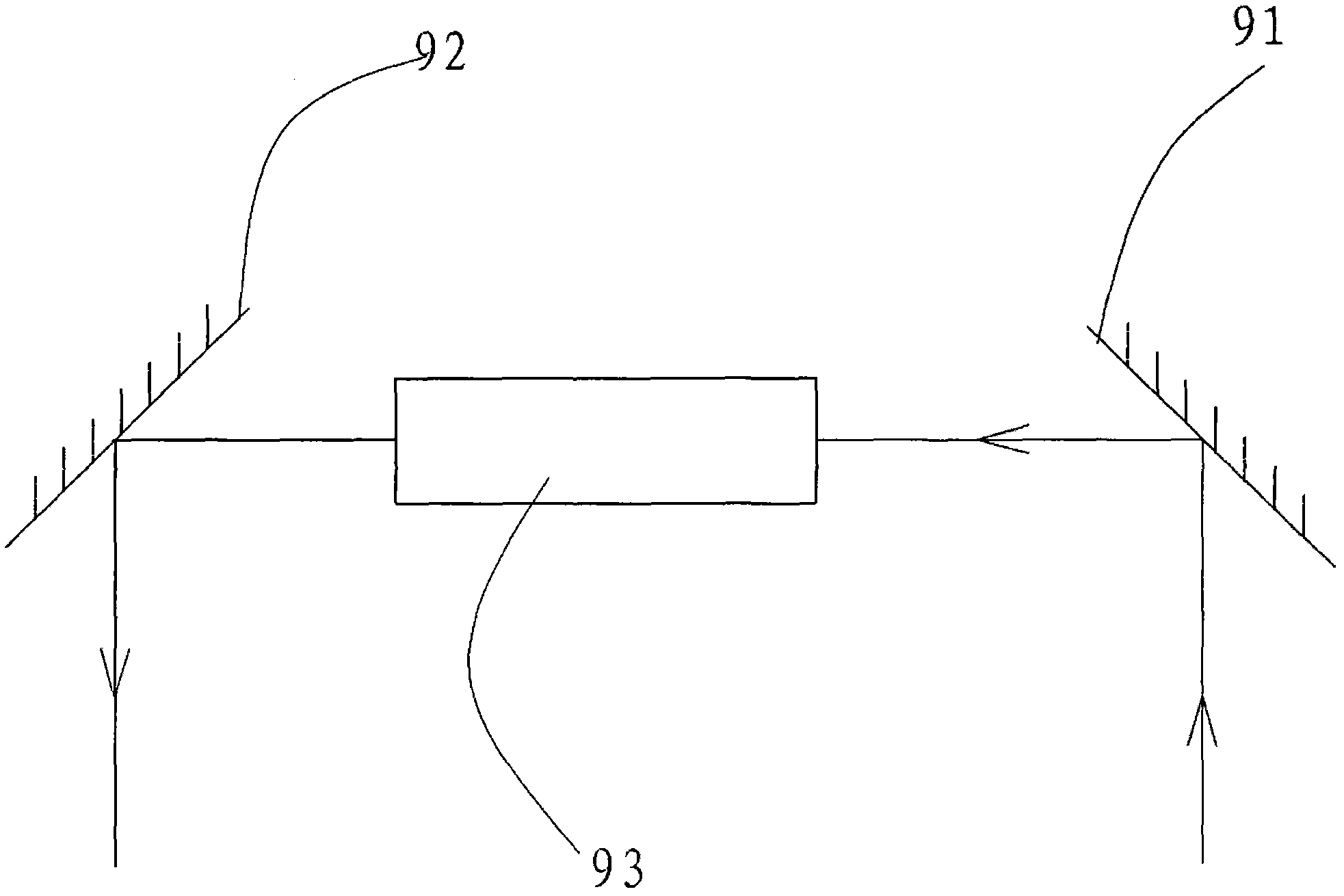

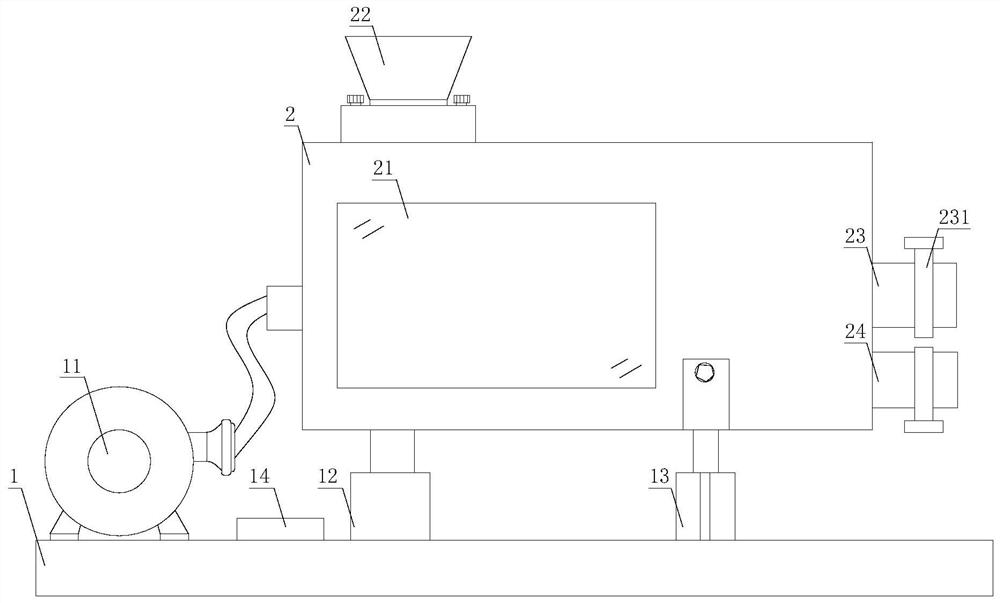

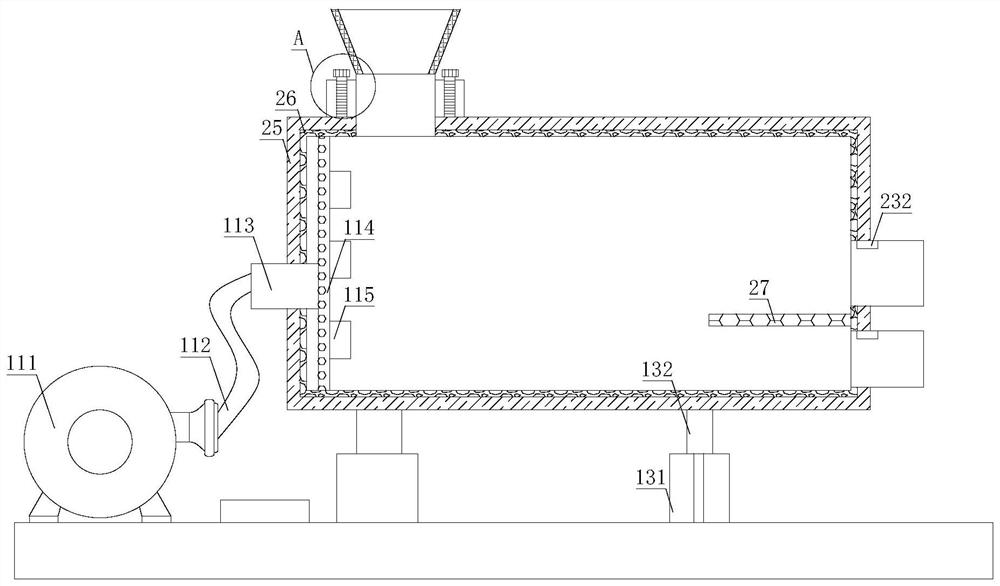

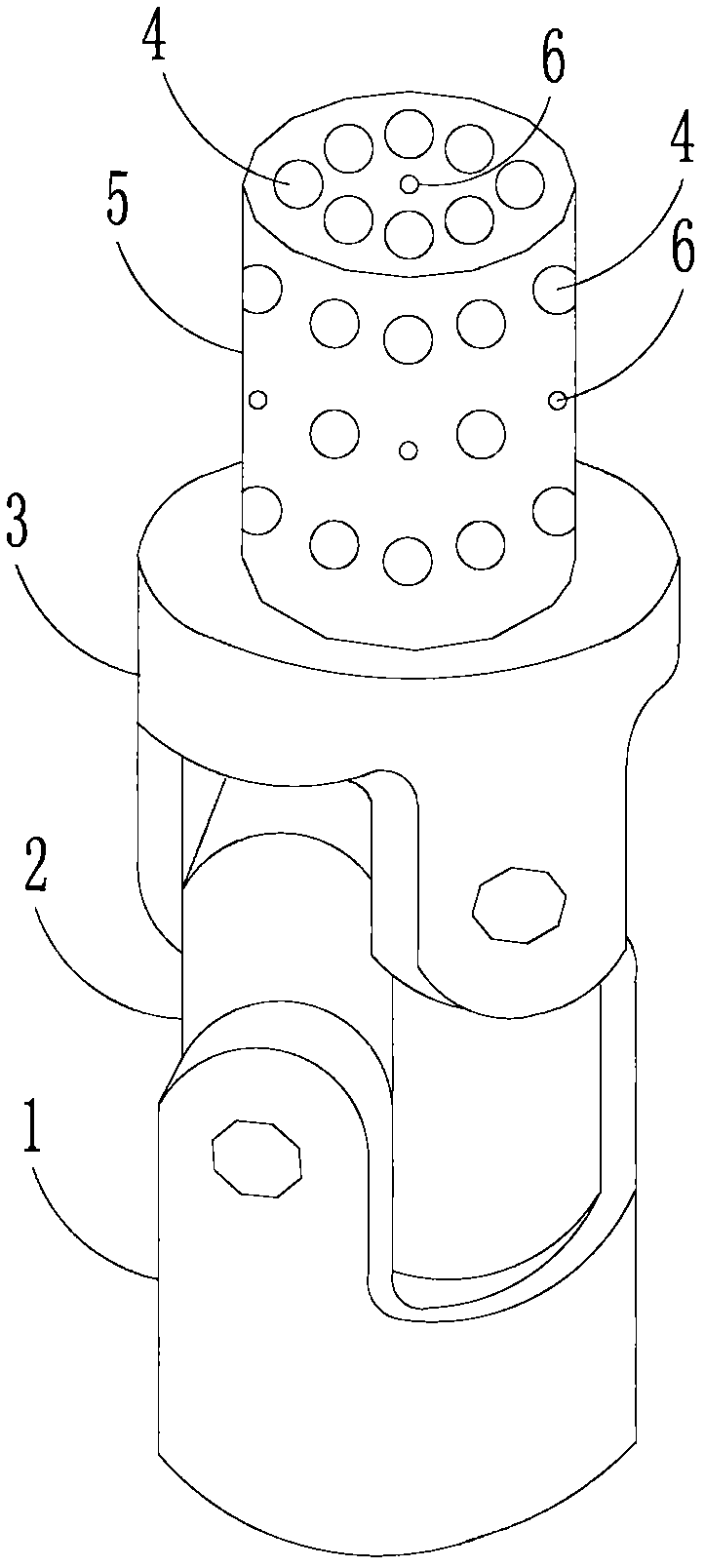

Rotary jet mixing low-energy consumption flotation equipment driven by utilizing ore pulp

The invention relates to the field of coal slime flotation treatment, in particular to rotary jet mixing low-energy consumption flotation equipment driven by utilizing ore pulp. The rotary jet mixing low-energy consumption flotation equipment at least comprises a flotation groove, wherein jet driving mixers are arranged in the flotation groove; each jet driving mixer comprises a driving turbine and a swirl jet mixing rotor which are separately connected to the upper part and the lower part of a rotary shaft, and the rotary shaft rotates under the joint action of driving force of the corresponding driving turbine and nozzle jet reactive force; the residue power of conveyed ore pulp is fully utilized, so that flotation mixing in the groove is realized; the rotary jet mixing low-energy consumption flotation equipment further comprises micro foam generation beds which are formed by micro foam generation pipes and are divided into an upper layer and a lower layer; the micro foam generation beds are arranged in a staggered manner and are not coincided with each other; micro foam generation holes are uniformly distributed in each micro foam generation pipe; and the left end and the right end of the micro foam generation beds are separately provided with a gas pipeline and a cleaning water pipeline. The rotary jet mixing low-energy consumption flotation equipment has the advantages that mixing energy consumption is low; the micro foam flotation effect is good; no flotation dead zones exist in the flotation groove; a foam layer is more stable; the work efficiency and the flotation effect both can be effectively ensured.

Owner:滦平县小营乡利民矿业有限公司

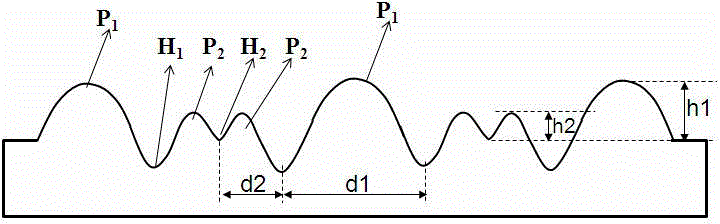

Graphical sapphire substrate and light emitting diode

ActiveCN104465926AEliminate threading dislocationsImprove crystal qualitySemiconductor devicesEpitaxial materialGallium nitride

The invention discloses a graphical sapphire substrate, a manufacturing method of the graphical sapphire substrate and the light emitting diode with the substrate. The graphical sapphire substrate is provided with a first surface and a second surface, wherein the first surface and the second surface are opposite, and no C surfaces, namely, 0001 surfaces exist in connection regions between all first protrusion parts. No C surfaces exist on the growth surfaces of the graphical sapphire substrate, and therefore the penetration dislocation density of a gallium nitride epitaxial material on the sapphire substrate is reduced.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

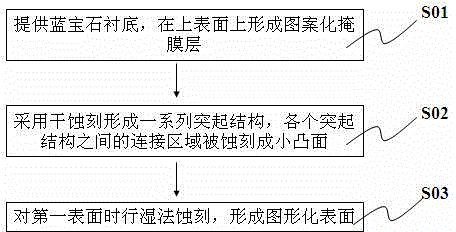

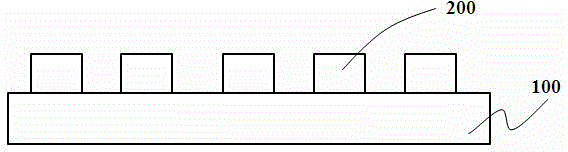

Method for manufacturing patterned sapphire substrate

ActiveCN104485402AEliminate threading dislocationsImprove crystal qualitySemiconductor devicesDry etchingSapphire substrate

The invention discloses a method for manufacturing a patterned sapphire substrate. The method comprises steps as follows: 1), a sapphire substrate is provided and has a first surface and a second surface which are opposite, and a patterned mask layer is formed on the first surface; 2), a series of bulge structures are formed on the first surface through dry etching, and connecting area between adjacent bulge structures is etched into small convex surfaces; and 3), the first surface of the sapphire substrate is subjected to wet etching, so that the patterned surface is formed, a series of regularly arranged first bulge parts are formed on the patterned surface, each first bulge part has a first size d1, and a connecting area between adjacent first bulge parts is free of a surface C, namely, the surface (0001).

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

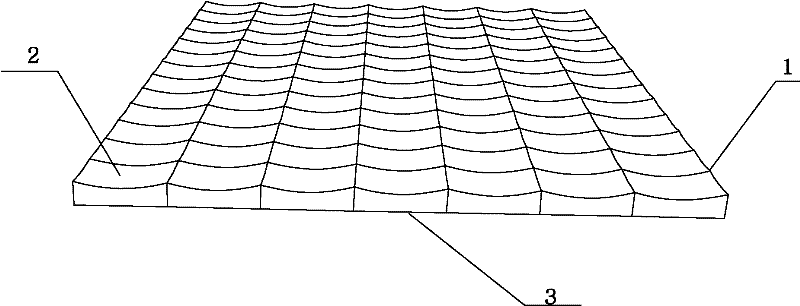

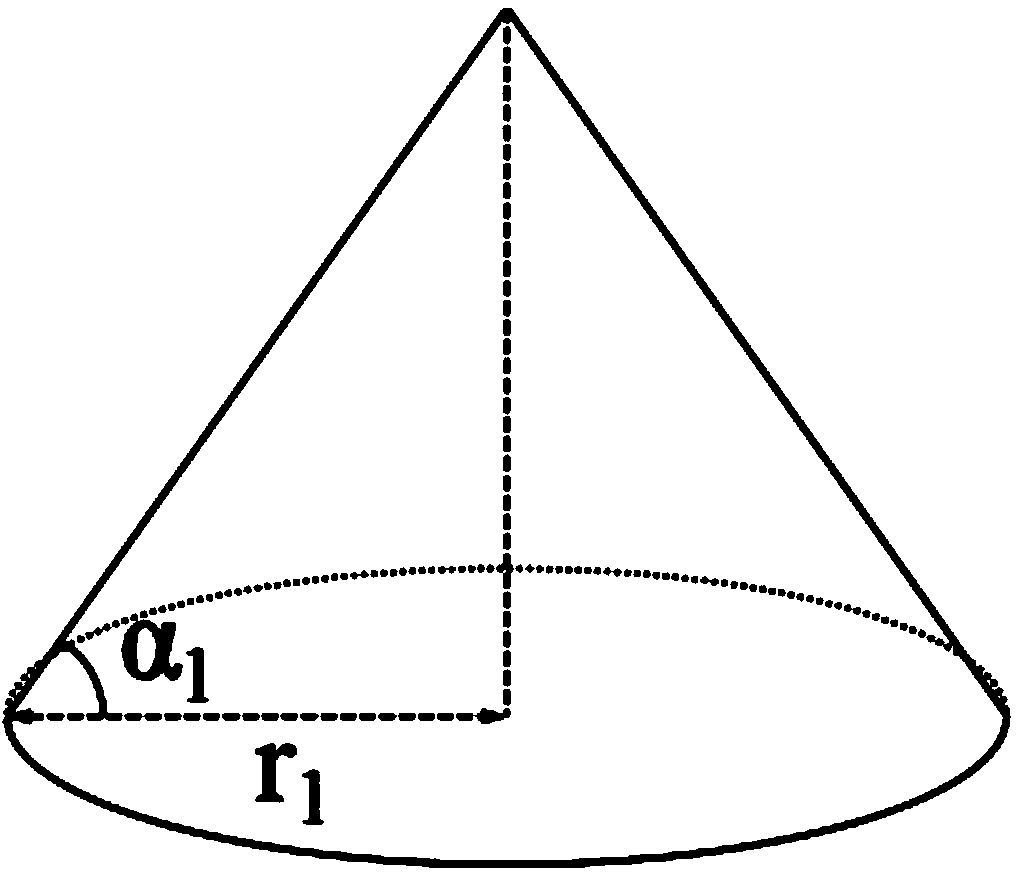

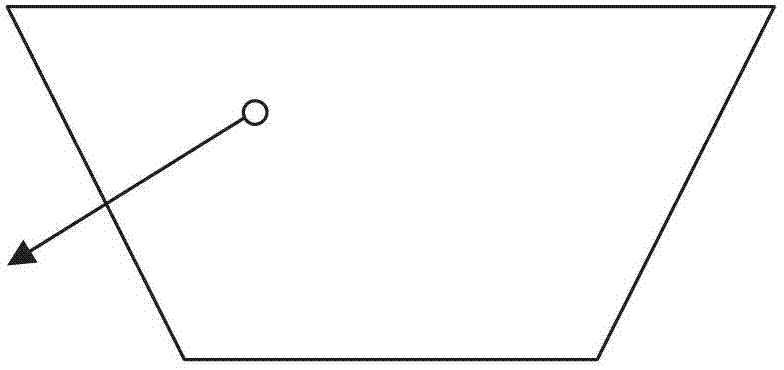

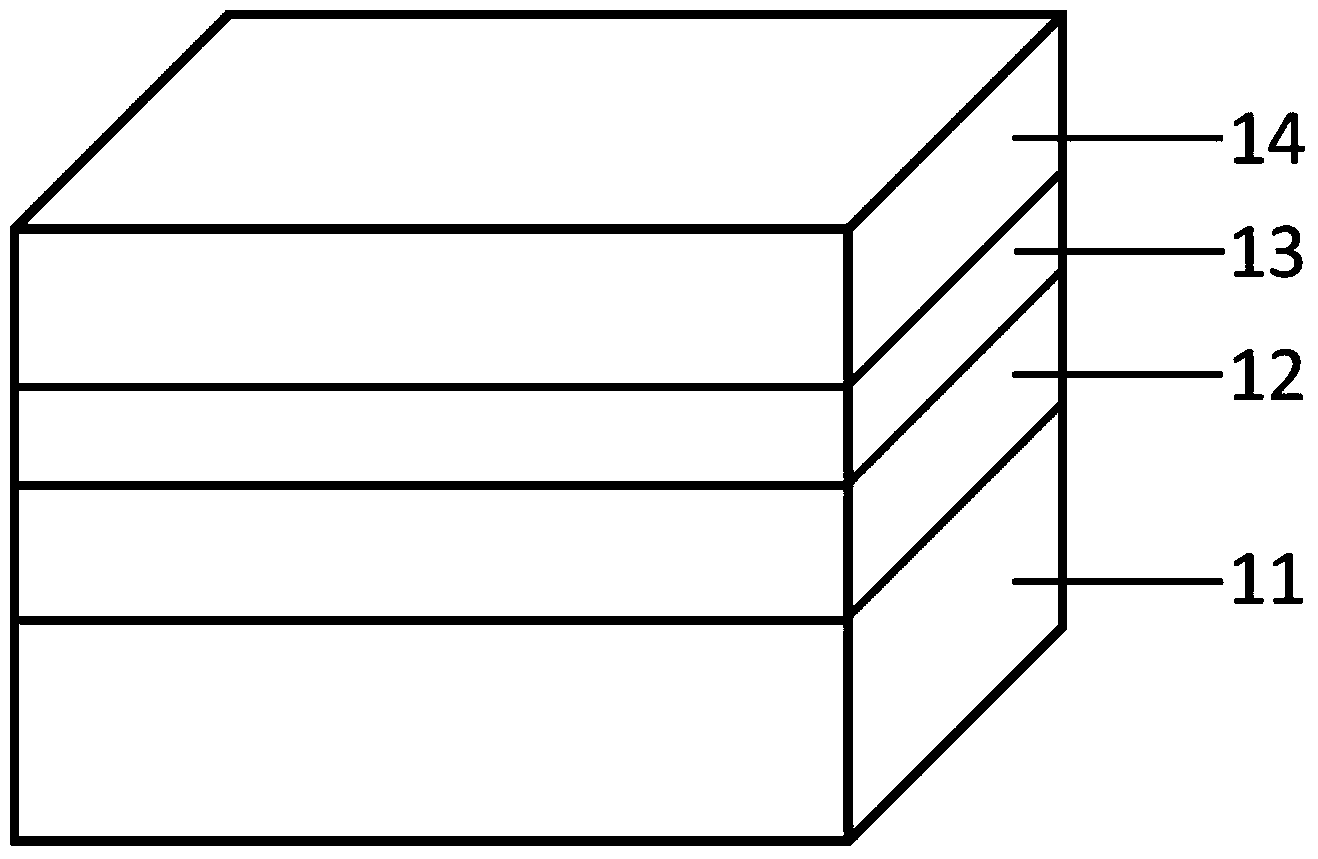

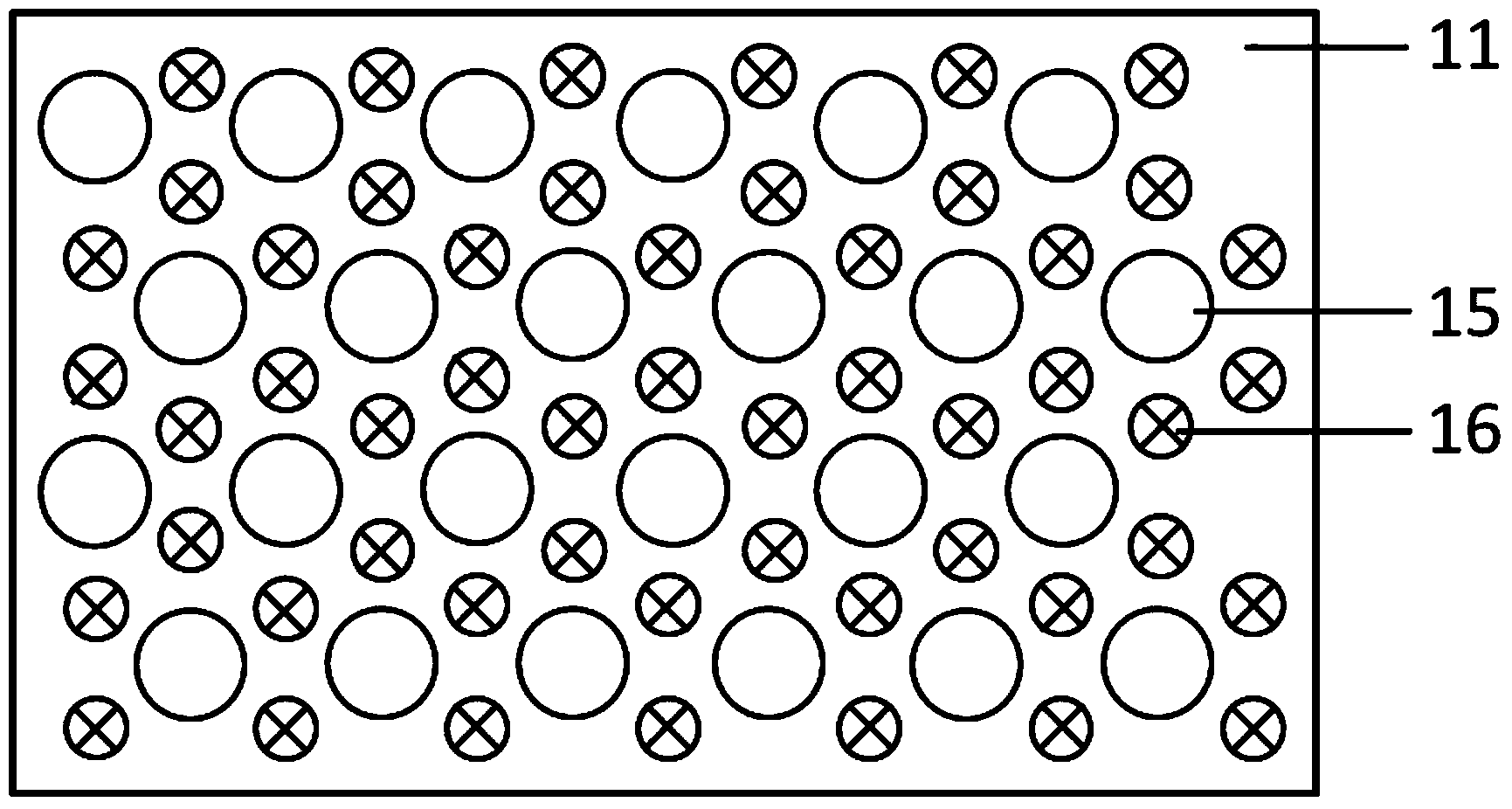

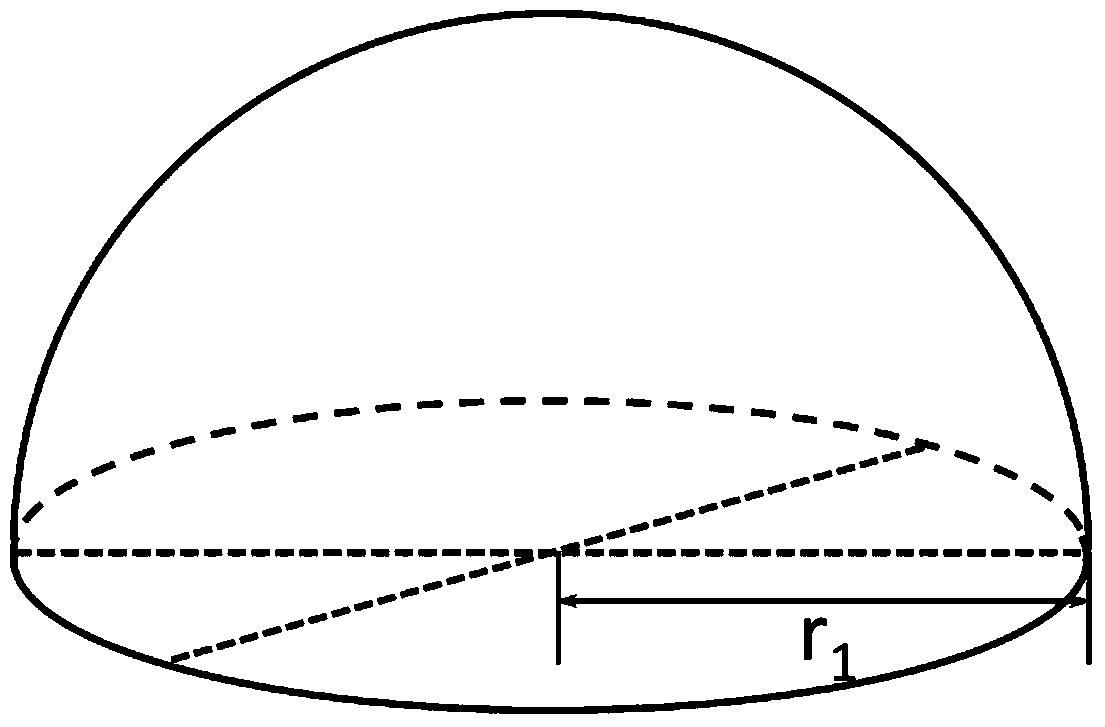

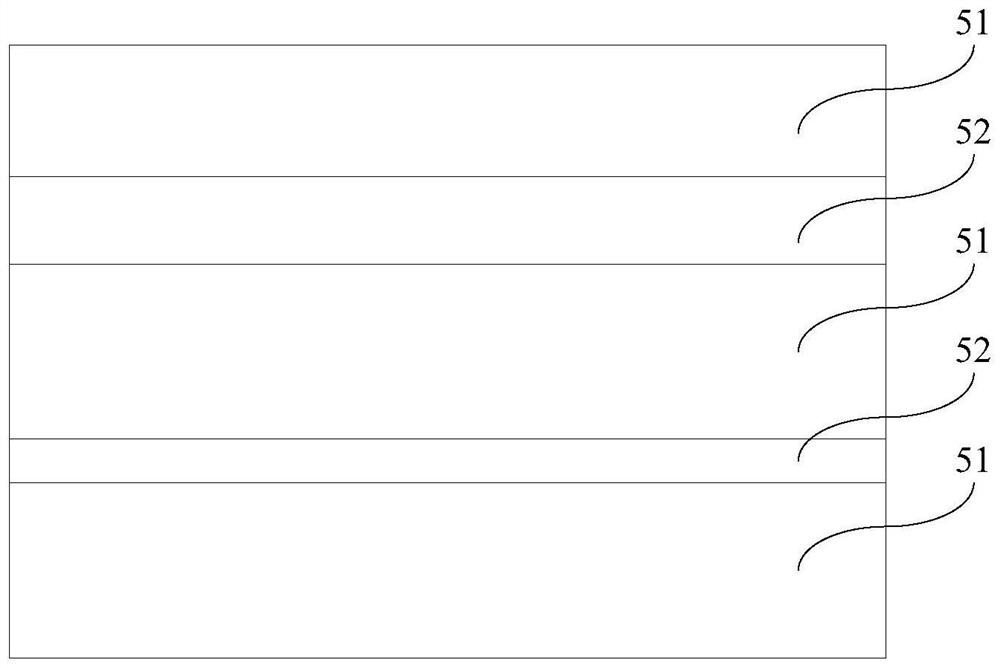

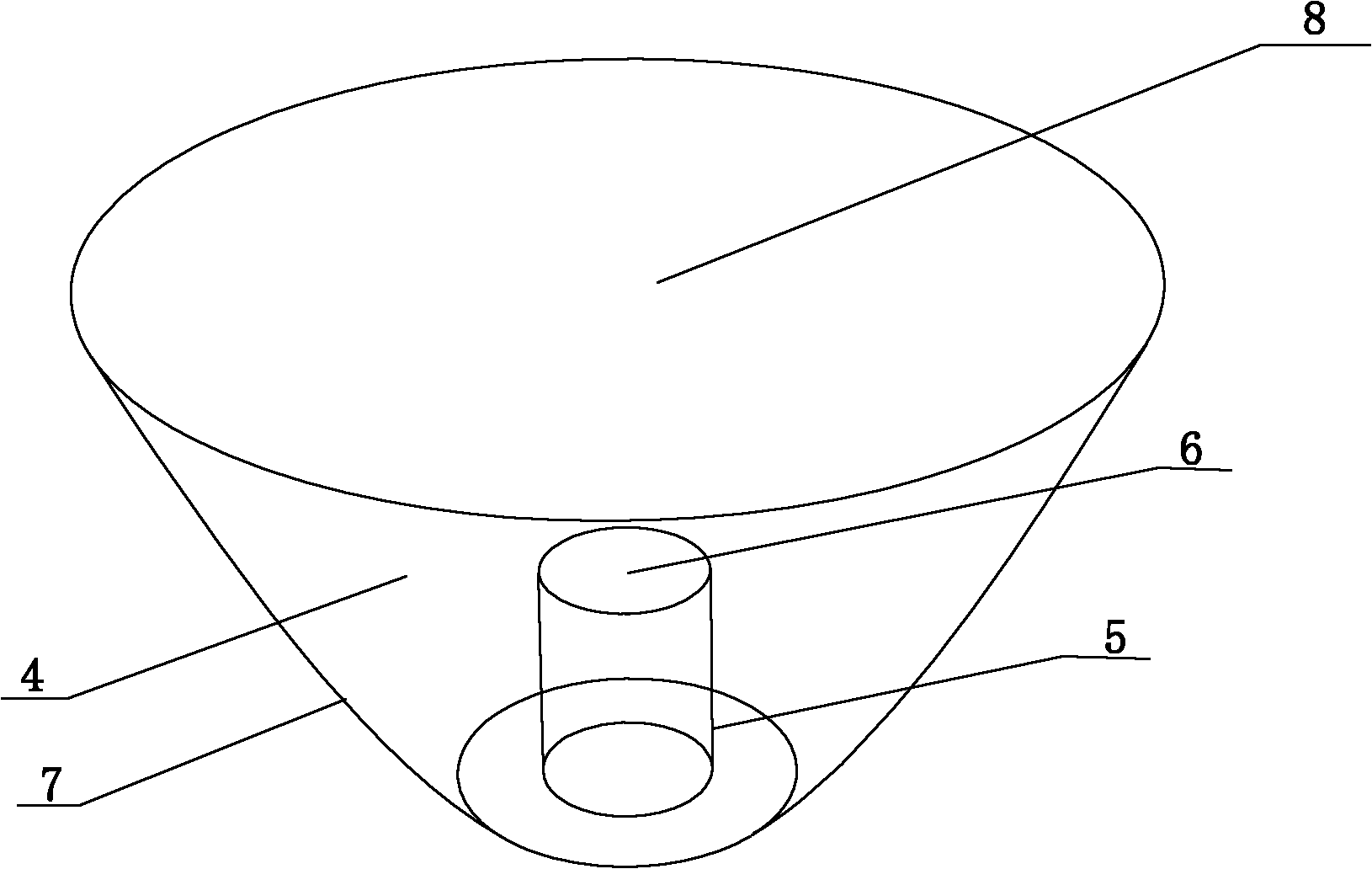

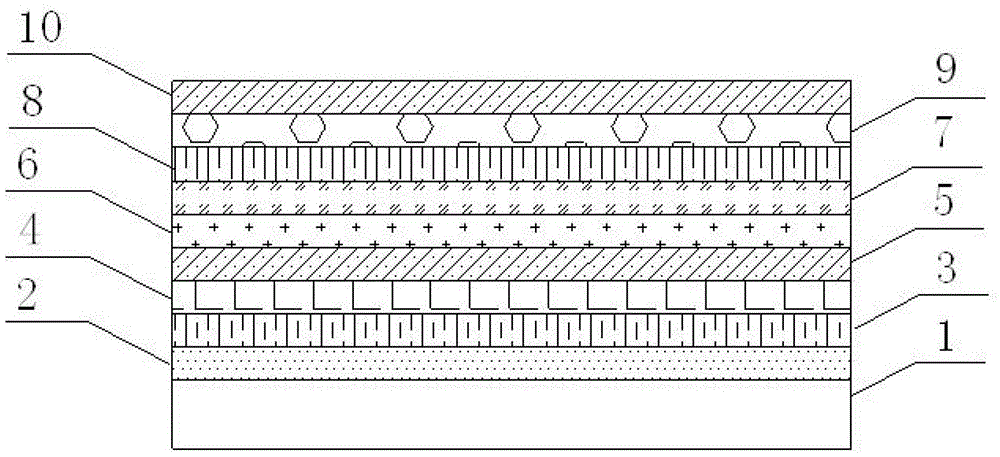

Dual-pattern LED patterned substrate and LED chip

InactiveCN104078542AImprove light extraction efficiencyGood for injectionSemiconductor devicesOptoelectronicsPatterned substrate

The invention discloses a dual-pattern LED patterned substrate. Patterns on the substrate include the hemispherical pattern and the conical pattern. The radius r1 of the bottom circle of the hemispherical pattern is not equal to the radius r2 of the bottom circle of the conical pattern. The invention further discloses an LED chip comprising the dual-pattern LED patterned substrate. The light emitting efficiency of an LED is improved through the combination with the effect of the conical surface of the conical pattern and the spherical surface of the hemispherical pattern on optimizing the LED light emitting efficiency; the patterns on the substrate are dense, and therefore more light rays can be emitted out of the LED chip, especially, more light rays can be emitted out of the top and the bottom of the chip, and the LED light extraction ratio is greatly increased.

Owner:SOUTH CHINA UNIV OF TECH

A kind of anti-corrosion absorbing coating and preparation method thereof

ActiveCN107892871BImprove compatibilityImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceSolvent free

The invention provides an anti-corrosion wave-absorbing coating and a preparation method thereof, and relates to the field of electromagnetic wave absorbing functional paint. The anti-corrosion wave-absorbing coating comprises an acrylic polyurethane bottom layer, a wave-absorbing layer and an anti-corrosion surface layer which are arranged sequentially, wherein the anti-corrosion surface layer isprepared by coating solvent-free polyurethane paint on the surface of the wave-absorbing layer. The preparation method of the anti-corrosion wave-absorbing coating comprises the following steps of: spraying acrylic polyurethane paint on the surface of a substrate to form the acrylic polyurethane bottom layer; spraying wave-absorbing paint on the cured acrylic polyurethane bottom layer to form thewave-absorbing layer; and spraying the solvent-free polyurethane paint to the surface of the cured wave-absorbing layer to form the anti-corrosion surface layer. The anti-corrosion wave-absorbing coating has the advantages of high wave-absorbing capability and excellent corrosion resistance, and can solve the problem of insufficient corrosion resistance of existing wave-absorbing coatings, and the weather resistance and service life of the wave-absorbing coating are improved.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

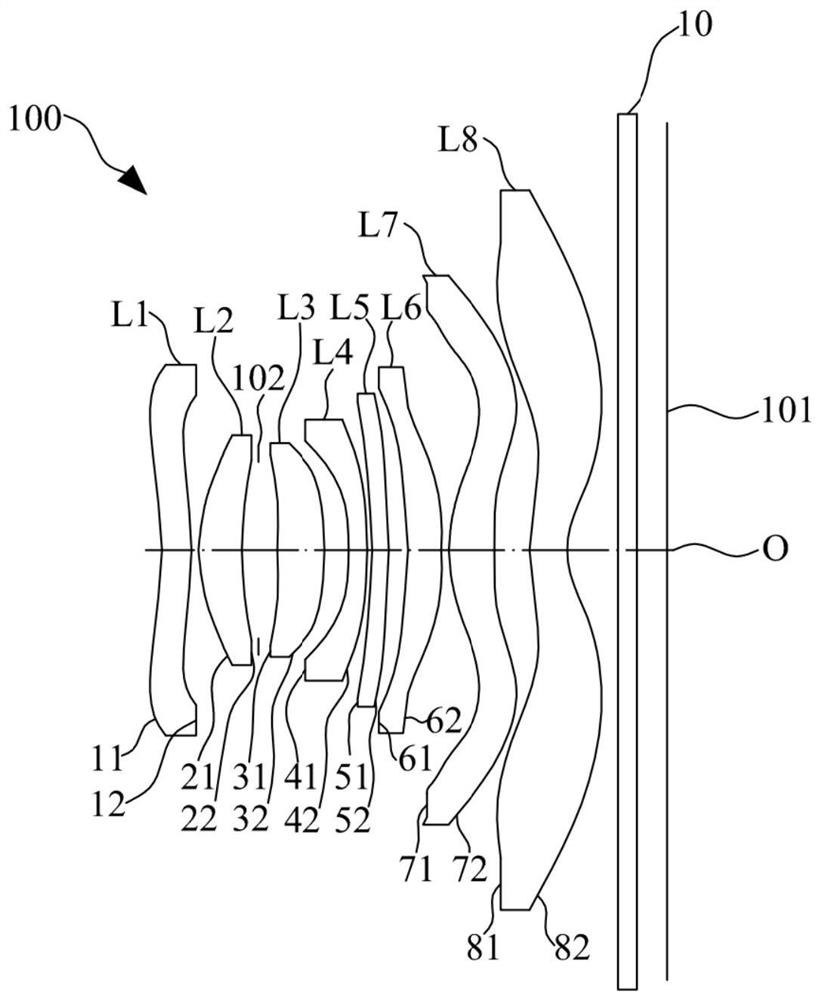

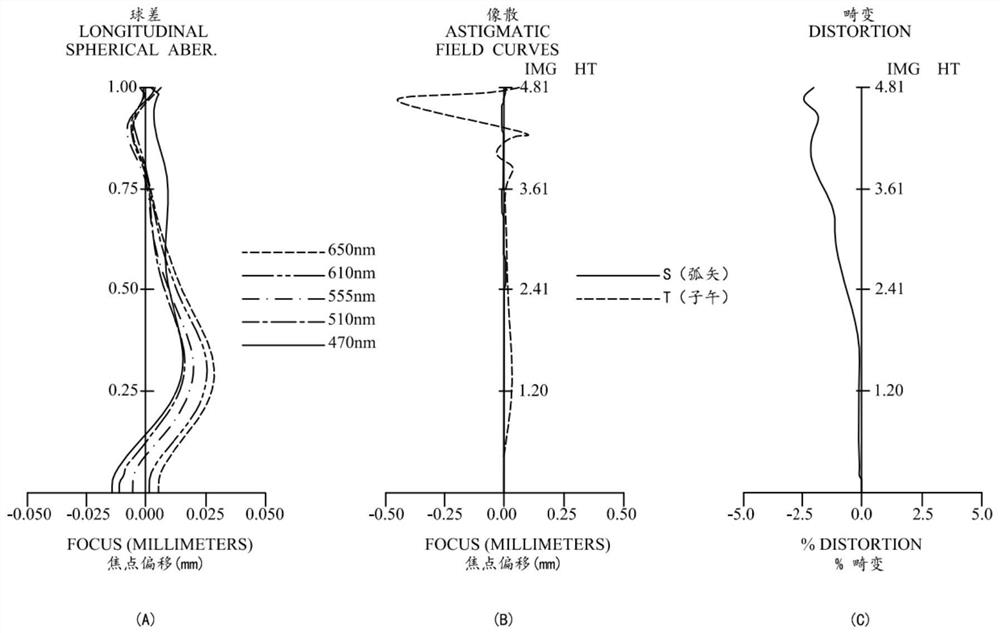

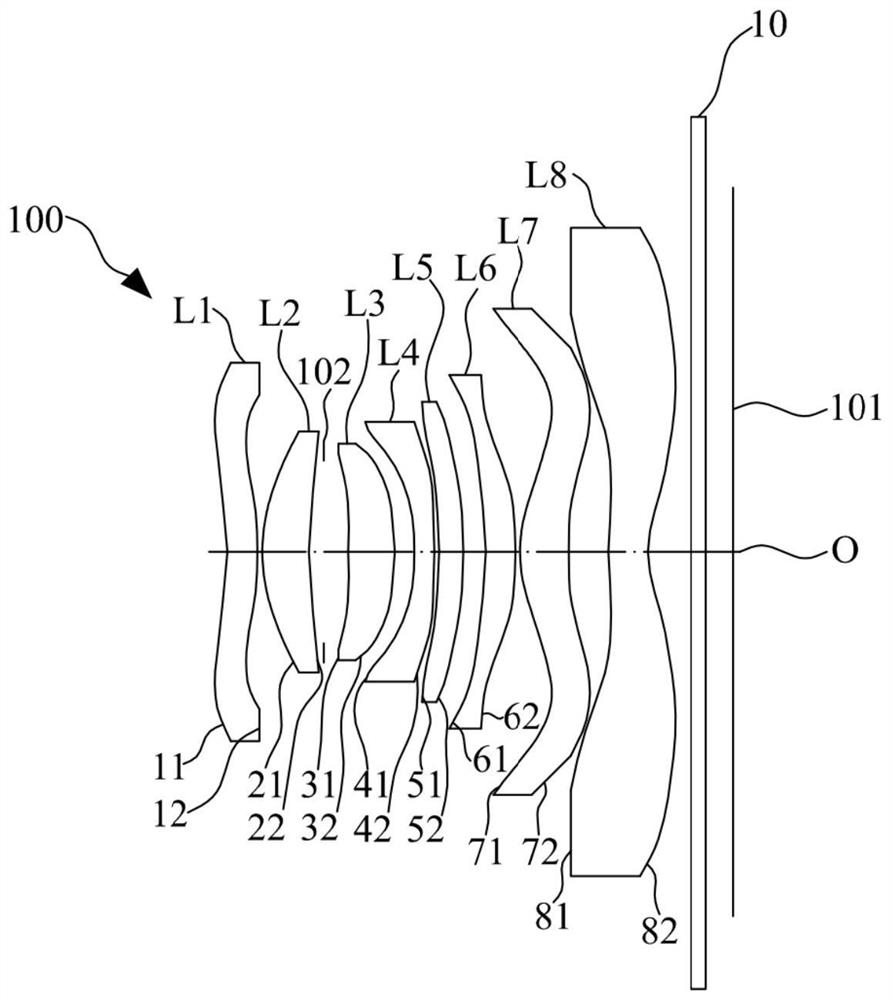

Optical lens, camera module and electronic equipment

PendingCN113741004AExpanded field of viewDelay edge ray angleOptical elementsOphthalmologyOptical axis

The invention discloses an optical lens, a camera module and electronic equipment, and the optical lens comprises a first lens which is sequentially provided with negative focal power from an object side to an image side along an optical axis, wherein the object side surface and the image side surface of the first lens are a concave surface and a convex surface; a second lens with positive focal power, wherein the object side surface and the image side surface of the second lens are a convex surface and a concave surface; a third lens with positive focal power, wherein the image side surface of the third lens is a convex surface; a fourth lens with focal power, wherein the object side surface and the image side surface of the fourth lens are a concave surface and a convex surface; a fifth lens with focal power, wherein the object side surface and the image side surface of the fifth lens are a concave surface and a convex surface; a sixth lens with negative focal power, wherein the object side surface and the image side surface of the sixth lens are a concave surface and a convex surface; a seventh lens with positive focal power, wherein the object side surface of the seventh lens is a convex surface; and an eighth lens with negative focal power, wherein the object side surface and the image side surface of the eighth lens are a convex surface and a concave surface. The optical lens also satisfies the following relational expression: 0.15 mm < TTL / (ImgH * 2) / f < 0.2 mm. According to the optical lens, the camera module and the electronic equipment provided by the embodiment of the invention, the shooting requirements of miniaturization and wide view can be met, and the imaging quality of the electronic equipment is improved.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

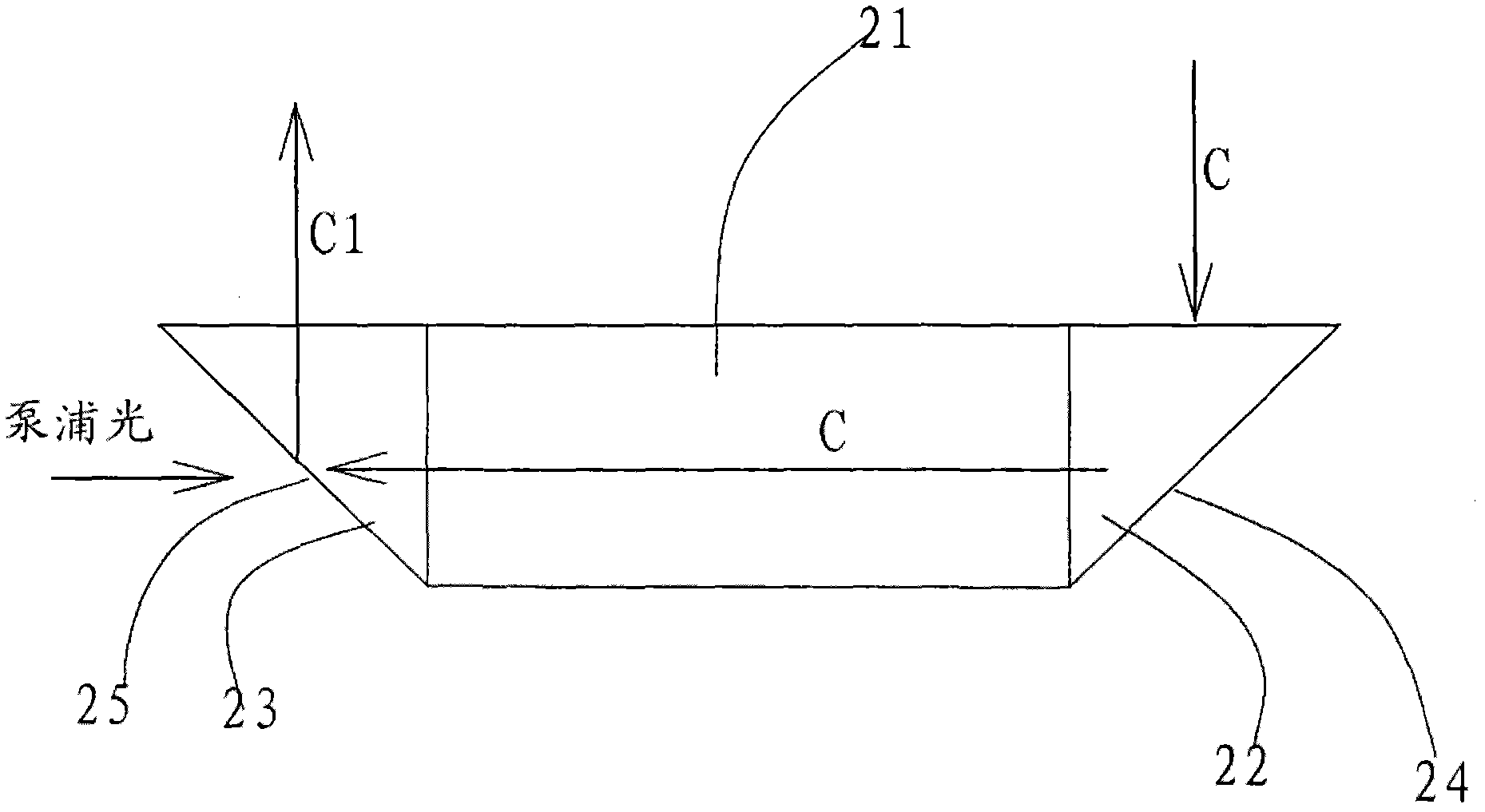

Composite laser crystal and laser provided with same

InactiveCN102487174AReduce in quantityReduce the difficulty of adjustmentActive medium materialActive medium shape and constructionOptoelectronicsLaser

The invention discloses a composite laser crystal and a laser provided with the composite laser crystal. The composite laser crystal comprises a laser crystal main body, wherein at least one end of the laser crystal main body extends outwards to form a matrix; the matrix comprises a first end surface, a second end surface and a third end surface; the first end surface is connected with the laser crystal main body; the second end surface is vertically connected with the first end surface and is positioned on the same plane with the top of the laser crystal main body; the third end surface is connected with the first and the second end surfaces; an anti-reflection film is arranged on the outer side surface of the third end surface in a plated manner; and a high-reflection film is arranged on the inner side surface of the third end surface in a plated manner. The composite laser crystal adopting the technical scheme has the advantages that the number of optical elements is decreased, the adjustment difficulty of the laser is reduced, and the stability of a system is improved; and since gain media are doped into the laser crystal, laser crystal deformation caused by uneven distribution of heat produced by two end surfaces of the laser crystal main body in the working process can be relieved.

Owner:BEIJING GK LASER TECH

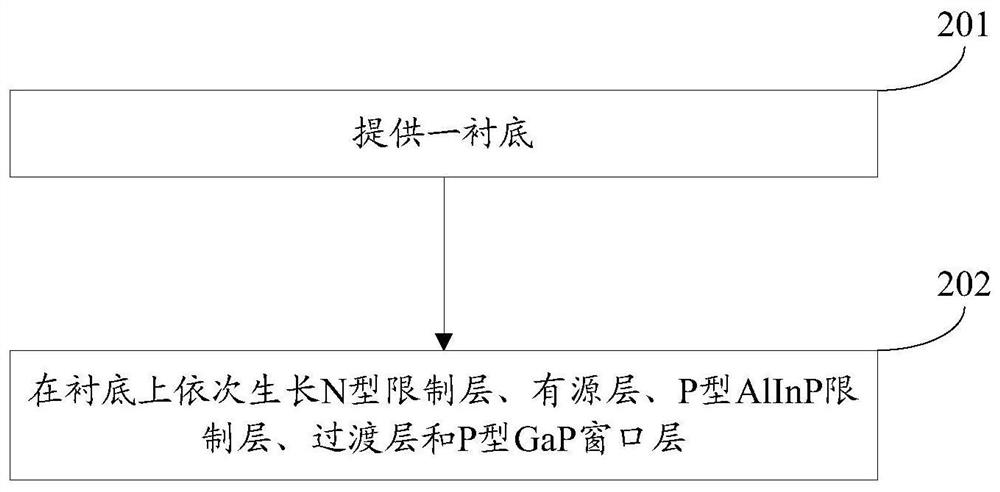

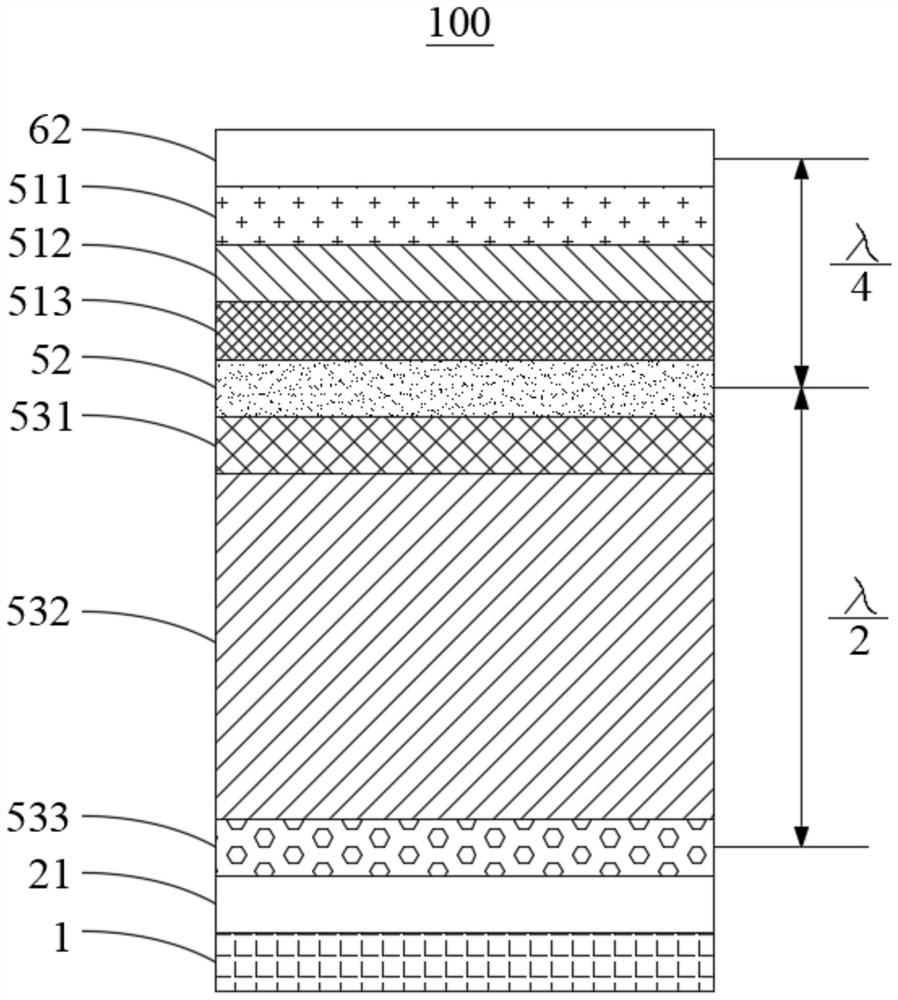

Light-emitting diode epitaxial wafer and growth method thereof

ActiveCN110379898BAffect light transmittanceAffect light transmittance reductionSemiconductor devicesCrystallographyActive layer

The invention discloses a light emitting diode epitaxial wafer and a growth method thereof, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, an N-type limiting layer, an active layer, a P-type AlInP limiting layer, a transition layer and a P-type GaP window layer, which are stacked in sequence. The transition layer comprises (N+1) first sub-layers and N second sub-layers, which are alternately stacked; each first sub-layer is an AlGaInP layer; the content of the Al component in the (N+1) first sub-layers is gradually decreased in the direction from the P-type AlInP limiting layer to the P-type GaP window layer, and the content of the Ga component in the (N+1) first sub-layers is gradually increased in the direction from the P-type AlInP limiting layer to the P-type GaP window layer; each second sub-layer is a GaP layer, and the total thickness of the N second sub-layers is 1 / 200-1 / 20 of the total thickness of the (N+1) first sub-layers. The light-emitting efficiency of an LED can be improved.

Owner:HC SEMITEK SUZHOU

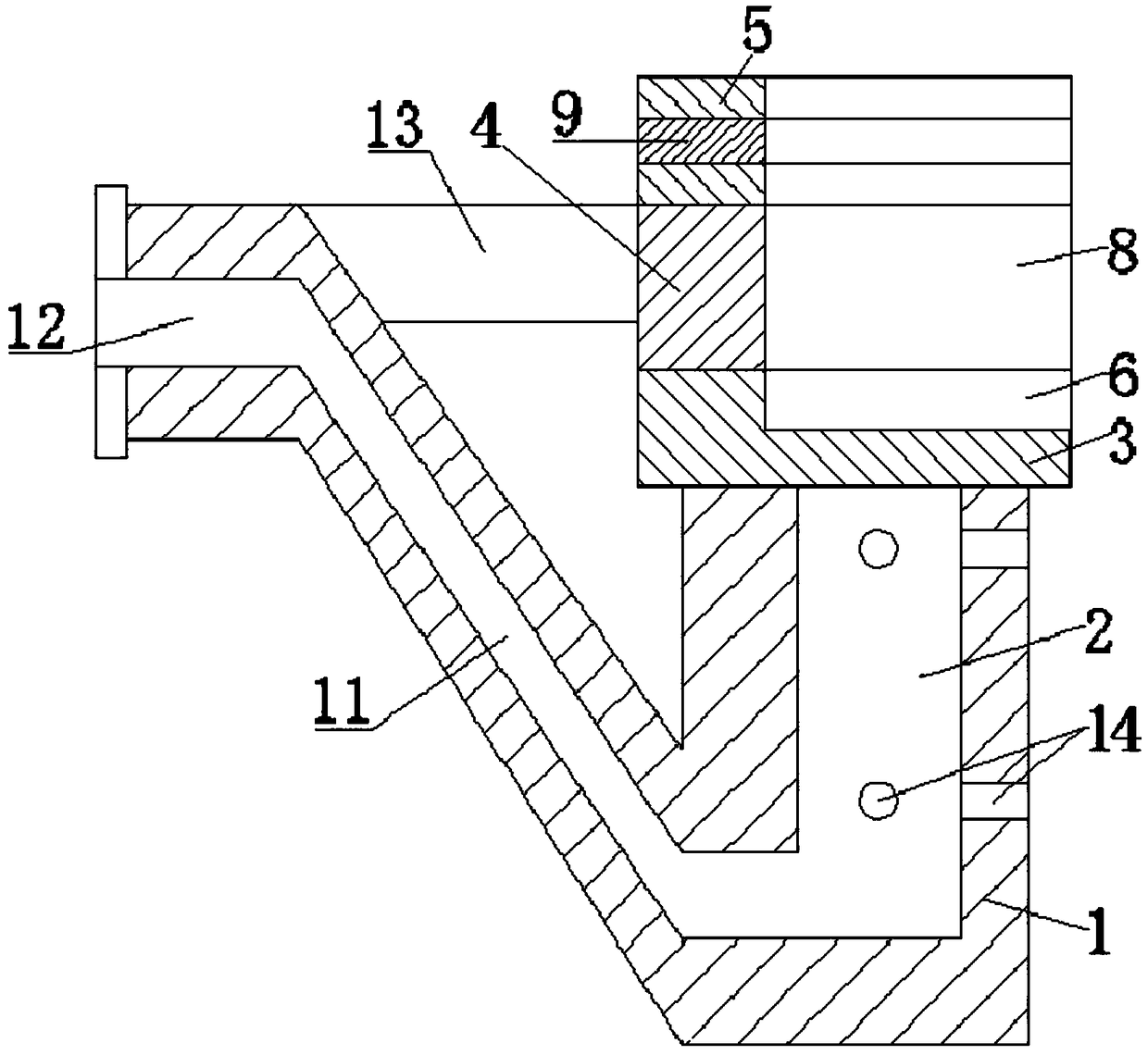

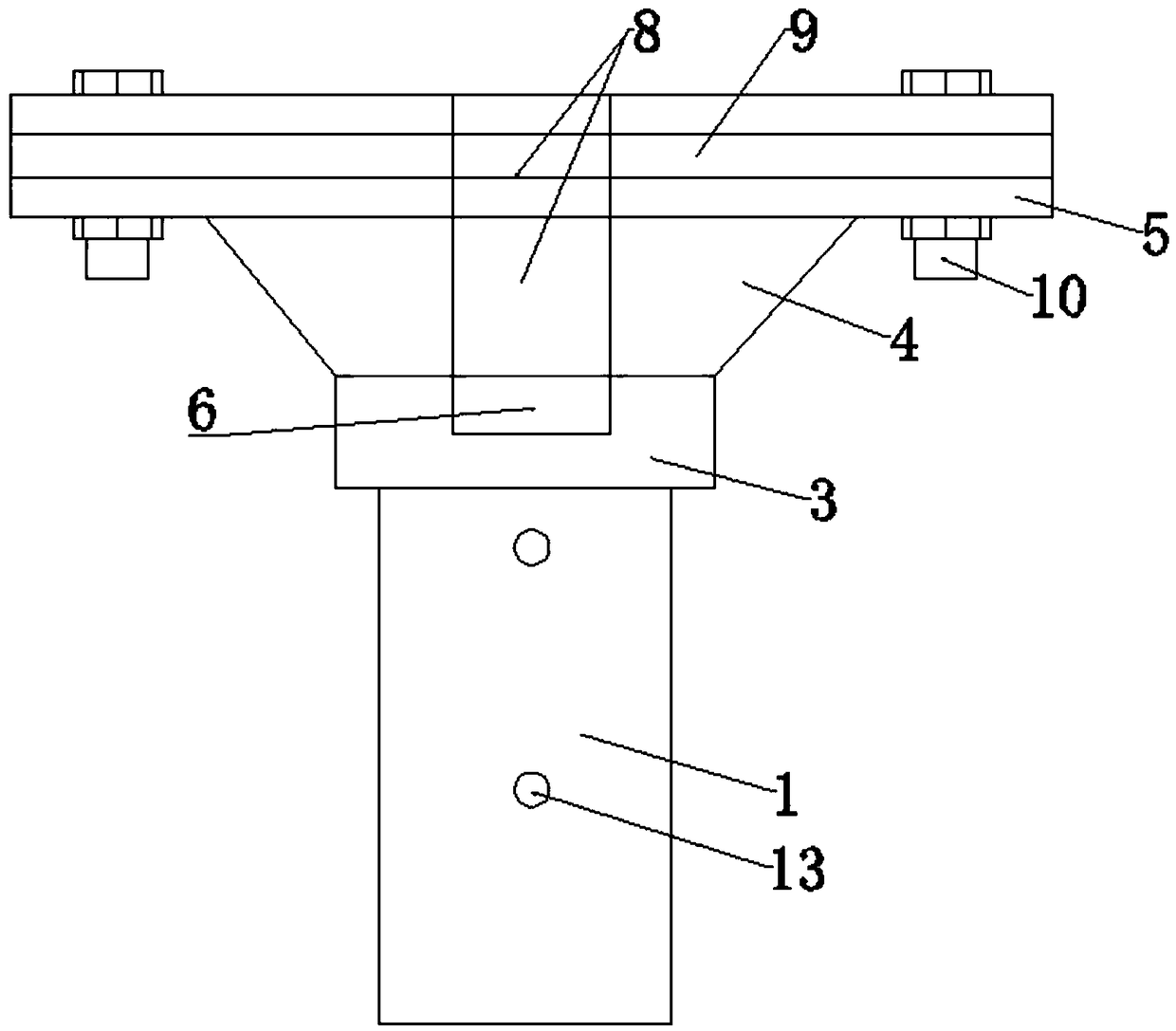

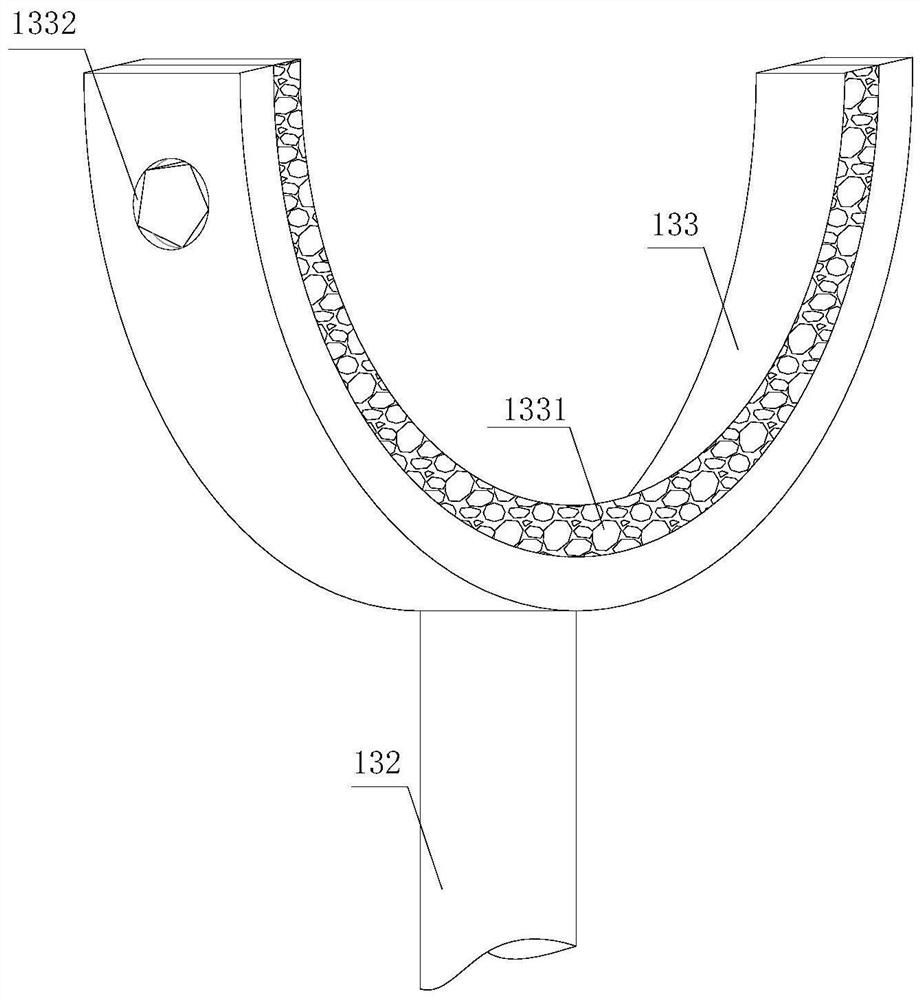

A Die Casting Machine Feed Pot with Reduced Heat Loss

The invention relates to the technical field of die-casting machines, and provides a die-casting machine material kettle for reducing heat losses. The die-casting machine material kettle comprises a kettle body, an injection chamber is arranged inside the kettle body, and a rectangular connecting body, a taper connecting body and an installing plate are sequentially arranged at the edge of an opening in the upper portion of the kettle body; a U-shaped blind groove is formed in the rectangular connecting body, and a through hole is formed in the lower bottom face of the U-shaped blind groove to be communicated with the injection chamber; the taper connecting body and the installing body are each provided with a U-shaped through groove matched with the U-shaped blind groove in structure; a heat insulating interlayer is arranged at the middle portion of the installing plate, and a threaded hole and a fastening bolt are arranged at the edge of the installing plate; the bottom of the injection chamber is communicated with a material injection nozzle through a material injection pipe, and the upper end of the taper connecting body is provided with reinforcing ribs so as to be fixedly connected with the right end of the material injection nozzle; and a feeding hole is formed in the side wall of the kettle body. By means of the die-casting machine material kettle, the heat losses of the die-casting machine material kettle are greatly reduced, the material injection effect is improved, and the die casting quality and efficiency of a die-casting machine are better improved.

Owner:安徽得力汽车部件有限公司

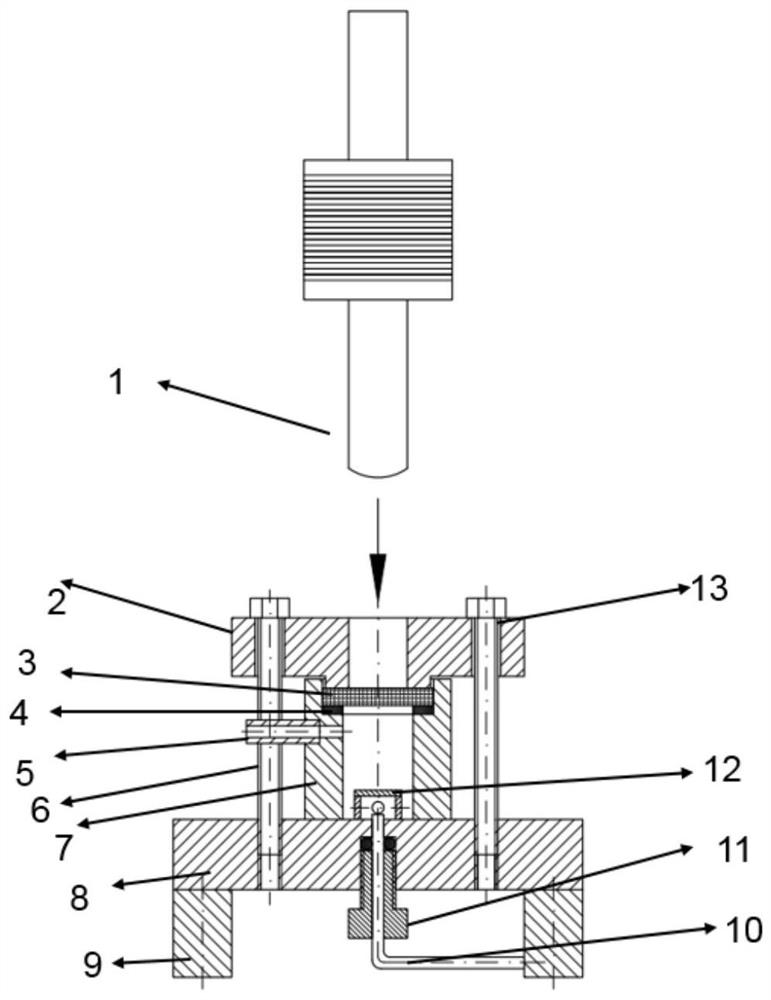

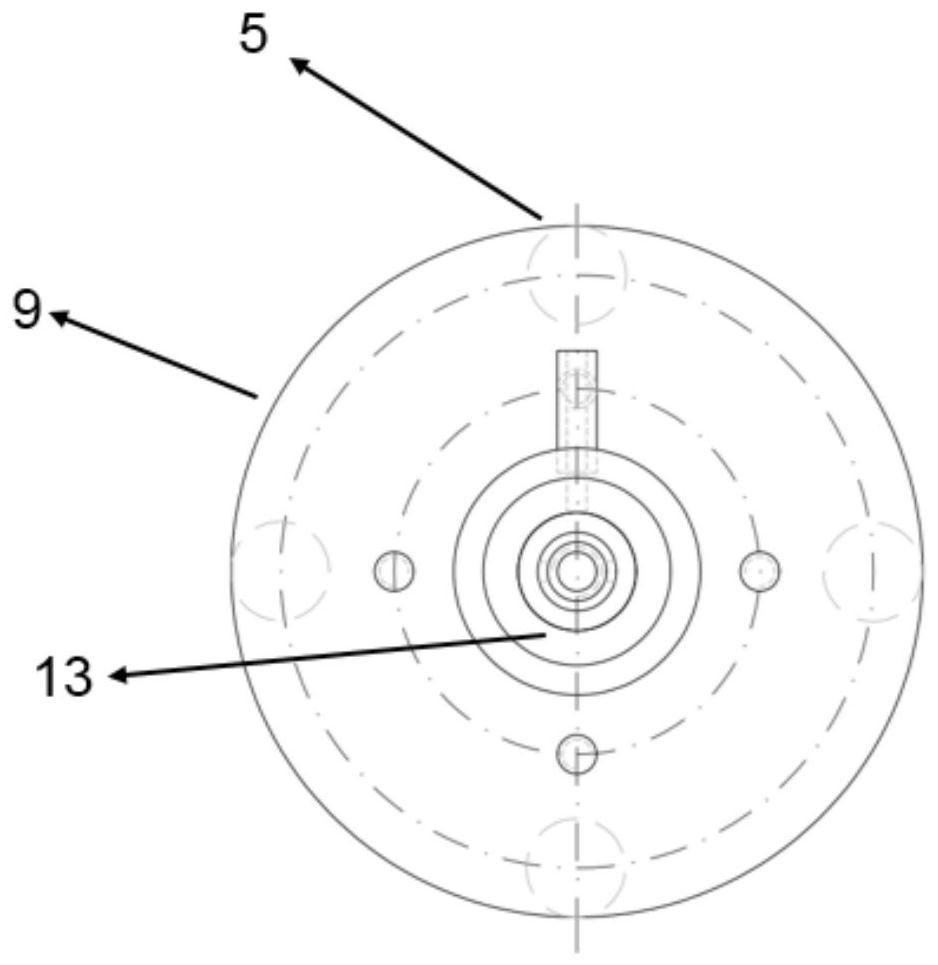

Adjustable sand shooting barrel for core shooter

InactiveCN111633186AImprove wear resistanceExtended service lifeMoulding machinesSolenoid valveElectric signal

The invention discloses an adjustable sand shooting barrel for a core shooter. The adjustable sand shooting barrel comprises a base and a barrel body. An adjusting structure is arranged at the upper end of the base, an air cylinder is arranged at the upper end of the base, a connecting rod is arranged at the upper end of the air cylinder, a clamping ring and the barrel body are fixedly mounted through a mounting hole, and a wear-resisting layer is arranged on the upper surface of the clamping ring, so that the wear resistance of the clamping ring is improved and the service life is prolonged.A control panel is utilized, so that the air cylinder moves up and down, and a retractable connecting rod is stretched and retracted, so that the clamping ring and the barrel body is driven for tilt angle adjustment. The automation degree is high and the application range of the barrel body is enlarged. Molding sand can be blown to directions of an upper sand outlet and a lower sand outlet throughan air opening, and the upper sand outlet and the lower sand outlet are each provided with a solenoid valve and a pressure sensor. When the pressure sensors sense pressure, pressure signals can be converted into electric signals, the solenoid valves can be switched on through the control panel so that the molding sand can be conveniently discharged from the upper sand outlet, and the operation issimple.

Owner:湖南汉寿玉贤耐磨材料有限公司

Light emitting diode (LED) lamp lens

InactiveCN102313245BReduce light lossGood for injectionPoint-like light sourceRefractorsLED lampLight-emitting diode

The invention discloses a light emitting diode (LED) lamp lens, which comprises a collimation lens, wherein the side face of the collimation lens is a total reflection face; a light outlet face of a sheet lens consists of convex faces of triangular convex lenses and concave faces of triangular concave lenses; and the collimation lens is provided with a refraction groove at an end plane opposite to the light outlet face of the collimation lens. Through the combination of the collimation lens and the sheet lens, the LED lamp lens is applicable to different LED chips and is more universal; and light which is emitted by the LED lamp lens is distributed uniformly and softer.

Owner:中国科学院宁波材料技术与工程研究所湖州新能源产业创新中心

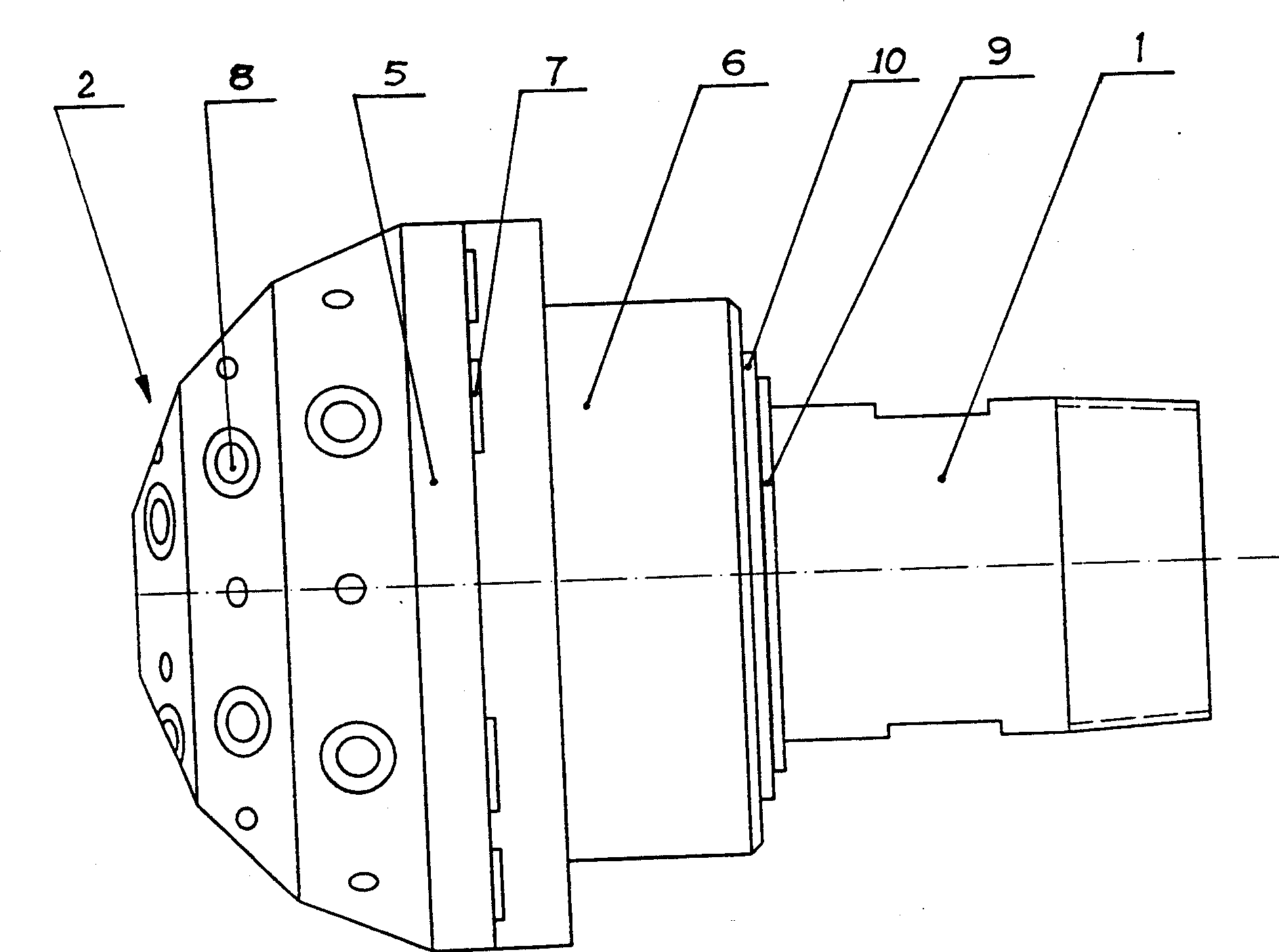

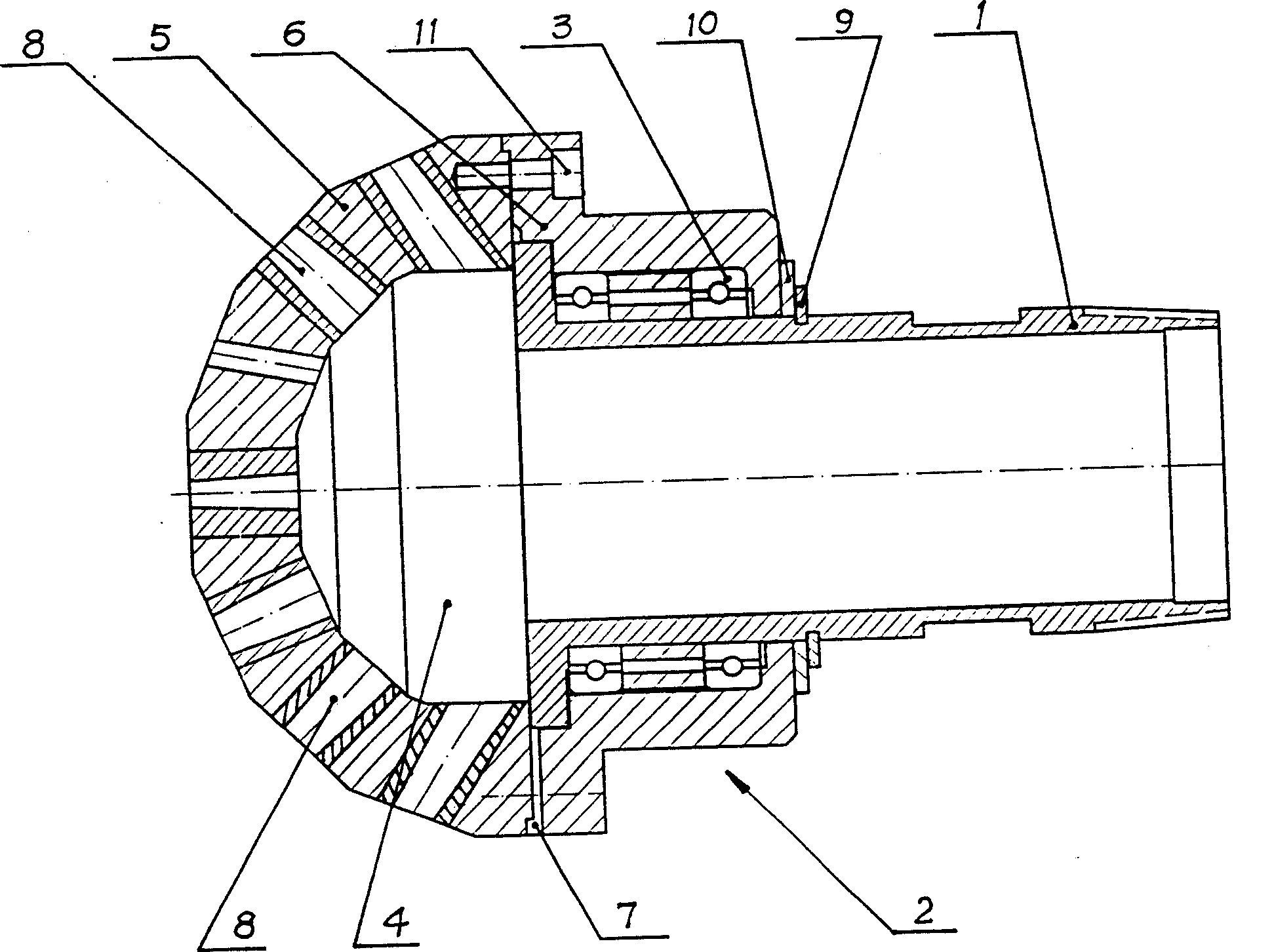

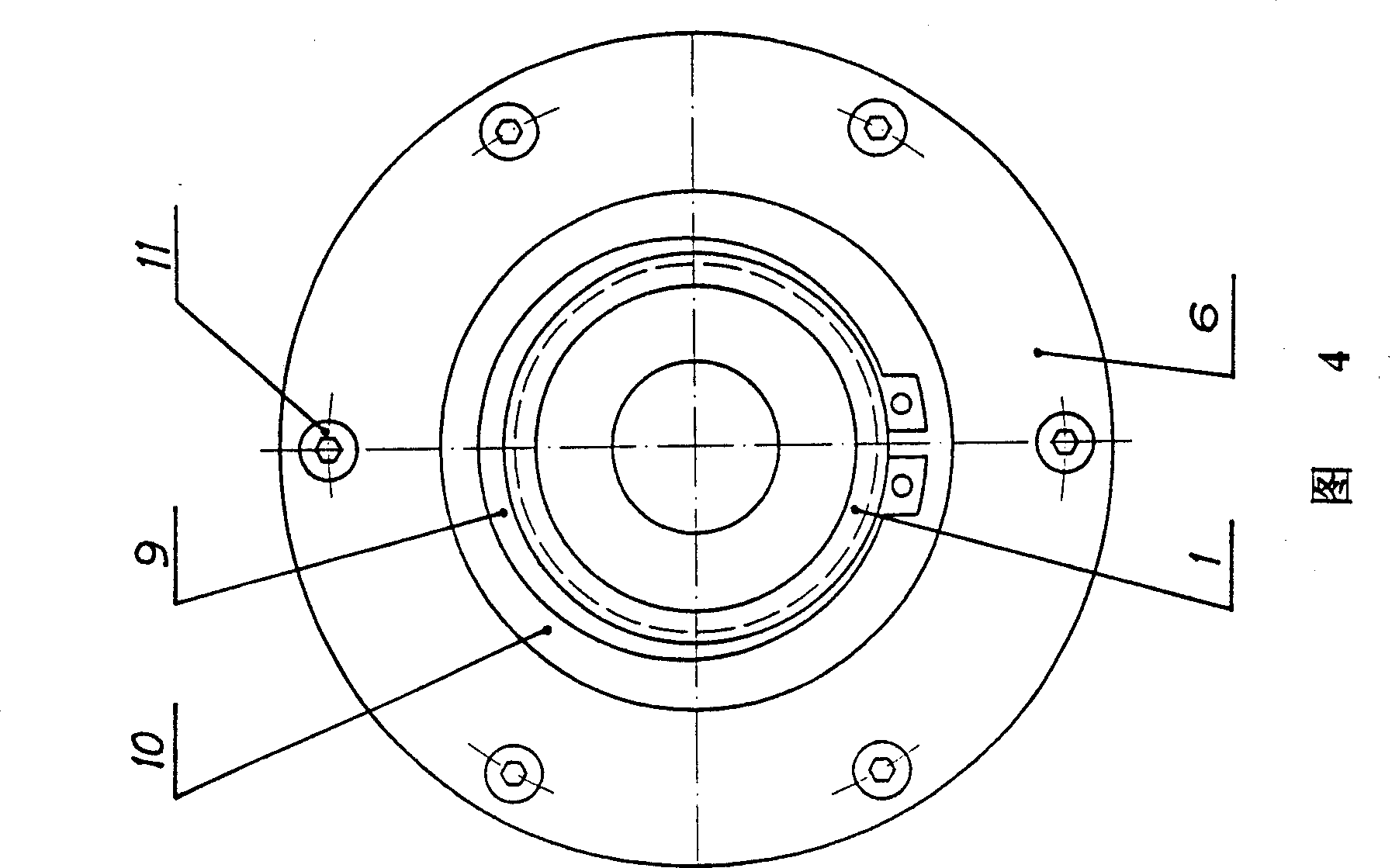

Rotation type ejecting fire extinguishing water cannon

InactiveCN100467089CRapid large area jet fire extinguishingGood for injectionFire rescueEngineeringSpherical shaped

Disclosed is a rotation type ejecting extinguishing water cannon, which comprises a water inlet pipe and a water nozzle body, wherein the water nozzle body is supported onto one end of the water inlet pipe through rotary members, the water nozzle body is provided with water chambers inside, the water chambers are in communication with the water inlet pipe, the water nozzle body comprises a front cover and a rear cover, a slot shape water shutting of air exhaust opening is arranged at the junction portion of the front cover and the rear cover. The front cover is in semi-spherical shape with a plurality of water outlets having ladder type cross sections, the inner caliber of the water outlet is larger than the outer caliber. The device can realize quick-speed large area sprinkling fire extinction.

Owner:颜月甜

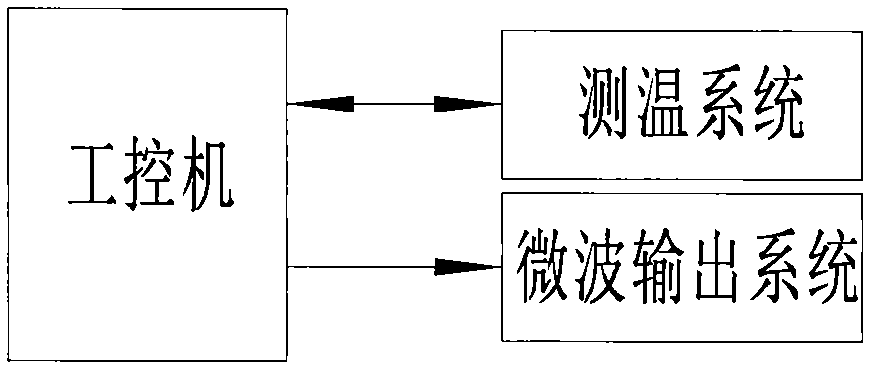

Three-dimensional targeted microwave tumor thermotherapy machine

PendingCN110448809AImprove the effect of hyperthermiaAvoid excessive heatTemperatue controlMicrowave therapyTemperature measurementAbnormal tissue growth

The invention discloses a three-dimensional targeted microwave tumor thermotherapy machine. The machine includes an industrial personnel computer, a microwave output system and a temperature measurement system; the industrial personnel computer is used for controlling starting or shutdown of the temperature measurement system, the temperature measurement system is used for detecting temperature information at a lesion in real time and sending the temperature information to the industrial personnel computer, the industrial personnel computer is used for controlling the output power of the microwave output system according to the temperature information, and the microwave output system is used for microwave thermotherapy of the lesion. According to the three-dimensional targeted microwave tumor thermotherapy machine provided in the embodiment, the temperature measurement system is used for detecting the temperature information of the lesion in real time, the industrial personnel computeris used for controlling the output power of the microwave output system according to the temperature information, and closed-loop control over the temperature and the output power is formed. On one hand, the microwave thermotherapy temperature of the lesion is ensured, and the thermotherapy effect is easily improved; on the other hand, the situation is avoided that the temperature of normal tissue around the lesion is over high in the thermotherapy process, and the safety and reliability of microwave thermotherapy are easily improved.

Owner:河北亿邦医疗设备股份有限公司

A light-thermal coupling microfluidic hydrogen production reaction device based on high-concentration point light source

The invention discloses a light-thermal coupling microfluidic hydrogen production reaction device based on a high-concentration point light source, which includes a high-concentration point light source, etc. When working, the direction of the high-concentration point light source is vertically downward; a catalyst placement table is placed at the bottom of the reaction chamber The center is aligned with the optical path of the high-concentration point light source; the catalyst is placed on the catalyst placement table, and the reactant is added inside the reaction chamber. The light source focuses light of different wavelengths on the surface of the photothermal catalyst, and the products after the reaction are collected and detected through the product sampling port. The reaction device of the present invention is small in size, and the size of each flow channel is small, which is convenient for the point light source to gather light on the catalyst carrier, and the energy flux density is greatly improved. At the same time, the gathering of strong light will carry heat, so as to realize the purpose of hydrogen production by photothermal coupling reaction. The invention has the advantages of simple structure, convenient operation, stable operation, good heat transfer effect and the like.

Owner:XI AN JIAOTONG UNIV

Imaging lens, camera device and portable information terminal device

ActiveCN102841433BShorten the lengthSignificant differenceOptical elementsNegative refractionCamera lens

The invention relates to an imaging lens, a camera device and a portable information terminal device, which can be used to provide an emitting-out pupil far away from the image surface, and is provided with a large-caliber small-sized high performance fixing imaging lens. The imaging lens is provided, from object side to image side, a first lens group (GR1) having the positive refraction ability or the negative refraction ability, a second lens group (GR2) having the positive refraction ability, and a third lens group (GR3) having the positive refraction ability. An aperture (Stop) is disposed between the second lens group and the image surface. The focusing can be realized by fixing the first lens group and moving the second lens group and the third lens group along the optical axis, and the condition can be satisfied, the F2 / F3 is less than 1.6 and larger than 0.5, the IFI / F is less than 20.0 and larger than 6.0, wherein the F is the focal length of the whole system of the imaging device by the infinity sharp focus, the F1, the F2, and the F3 are respectively the focal lengths of the first length group, the second length group, and the third length group.

Owner:RICOH KK

A kind of oled device

ActiveCN103022377BHigh extinction coefficientLower work functionSolid-state devicesSemiconductor/solid-state device manufacturingComposite cathodeEvaporation

The invention relates to an organic light-emitting diode (OLED) device which comprises a substrate and an anode, an organic layer and a cathode which are sequentially arranged on the substrate. The cathode is a transparent composite cathode and comprises an alloy layer of low work function metal and silver, a silver layer and an anti-reflection layer arranged on the silver layer. The work function of the low work function metal is smaller than 3.7eV, the molar ratio of the low work function metal and the silver in the alloy layer is 2:1-8:1, the thickness of the alloy layer is 3-11nm, the thickness of the silver layer is 15-30nm, and the thickness of the anti-reflection layer is 30-100nm. Magnesium, lithium, potassium and the like can be wrapped on the periphery of silver atoms when being evaporated with the silver together, the work function of the cathode can be effectively reduced by evaporation in proper proportion, and the cathode cannot absorb a large amount of visible light. The anti-reflection layer increases intensity of transparent light, is large in energy gap and does not affect color purity of the device. The thickness of the alloy layer and the silver layer is low, so that the alloy layer and the silver layer have high light transmittance.

Owner:KUNSHAN VISIONOX DISPLAY TECH +2

Optical lens, camera module and electronic equipment

ActiveCN113484997BOptical total lengthMeet miniaturization needsOptical elementsOphthalmologyOptical axis

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

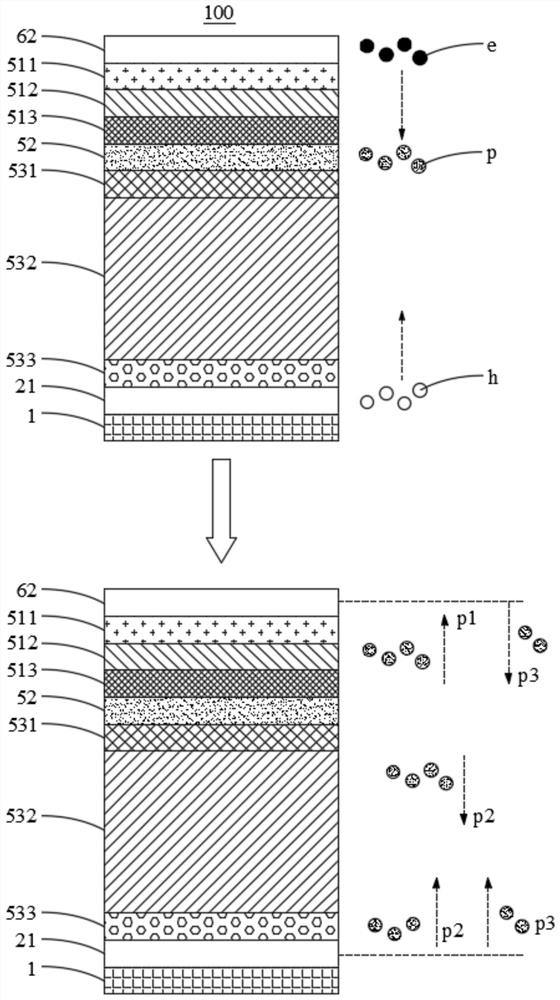

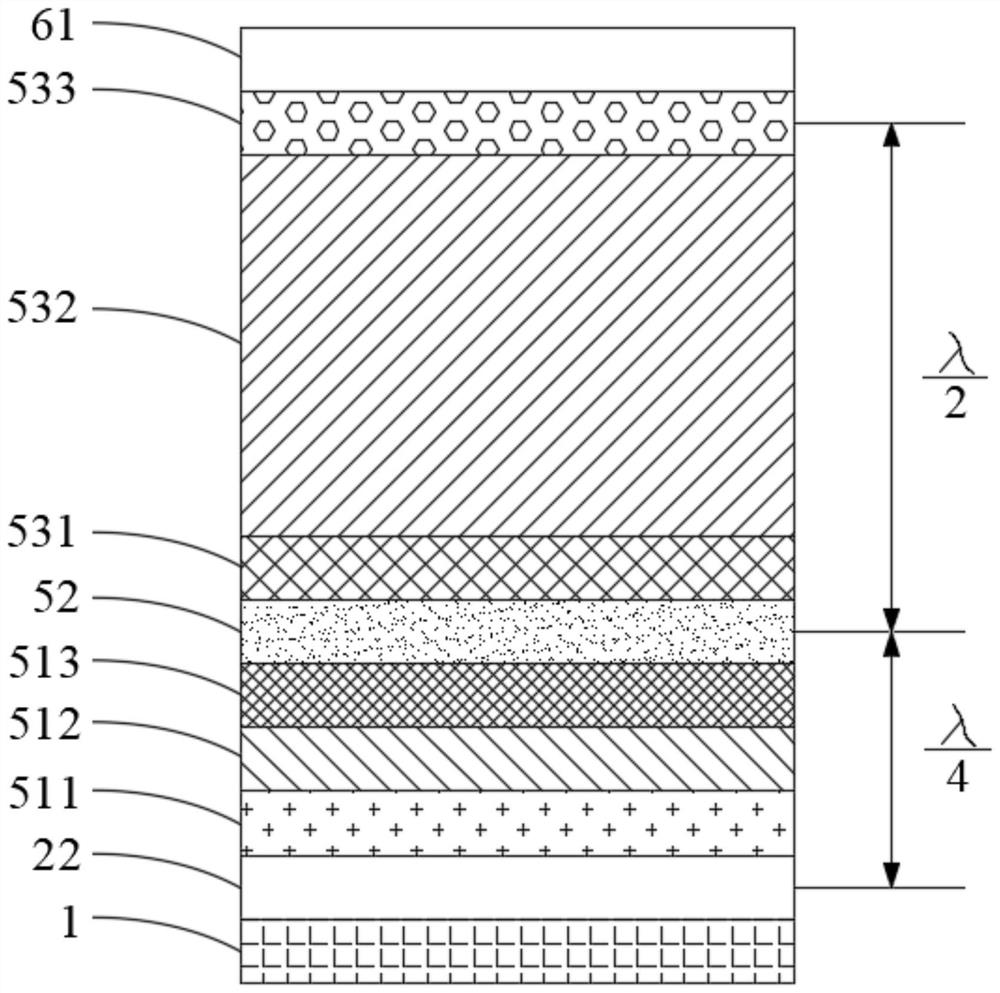

Organic light-emitting device and method of manufacturing organic light-emitting device

ActiveCN112599706AImprove external quantum efficiencyRealize normal light emissionSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductivePhotochemistry

The embodiment of the invention provides an organic light-emitting device and a method of manufacturing the organic light-emitting device, after the hierarchical structure of the organic light-emitting device is inverted, a transparent organic layer and a conductive layer are further added, and the conductive layer and a reflective cathode layer are in lap joint. By additionally arranging the transparent organic layer, the micro-cavity structure of the organic light-emitting device can be ensured not to be changed basically after being inverted compared with the micro-cavity structure before being inverted, so that photons generated by the light-emitting layer can be emitted out of the organic light-emitting device, and the external quantum efficiency of the inverted organic light-emittingdevice is improved. By additionally arranging the conductive layer, electrons generated by the reflective cathode layer can be injected into the light-emitting layer through the conductive layer, anda problem that the higher voltage needs to be applied due to poor conductivity of the transparent organic layer is solved. Due to the design, normal luminescence of the organic light-emitting deviceunder normal voltage can be realized on the premise of ensuring that the external quantum efficiency of the inverted organic light-emitting device is not reduced basically.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

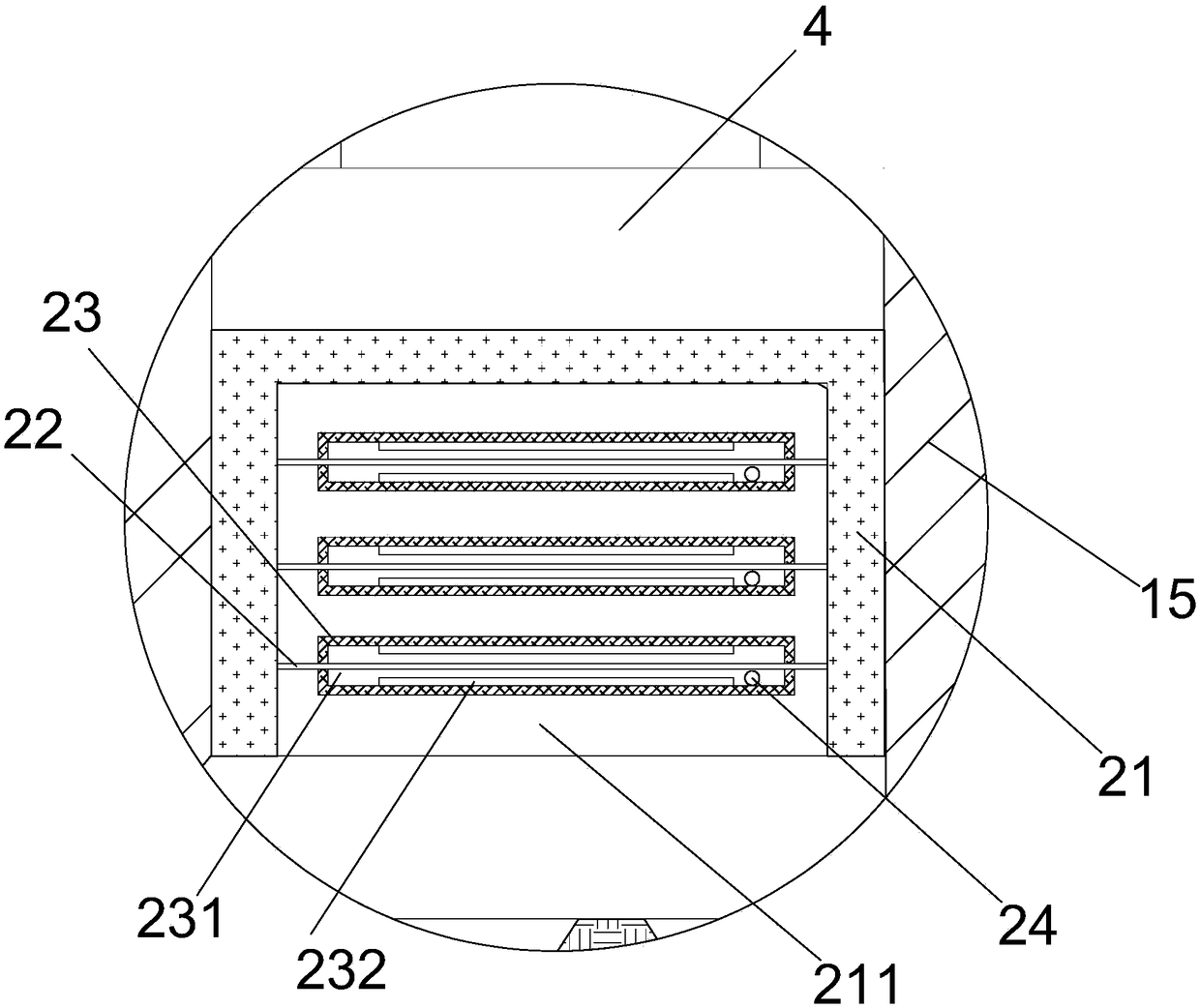

Liquid crystal display module with LED lamp located at outside of backboard

PendingCN109283742AGood for injectionIncrease cooling areaNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a liquid crystal display module with an LED lamp located at outside of a backboard. The liquid crystal display module comprises a display mechanism, a heat dissipation mechanism, a retroreflector and the LED lamp; the display mechanism comprises the backboard, a reflector, a light guide plate, an optical film material, a plastic frame, a liquid crystal display panel and anexternal frame; the reflector is mounted on the backboard, the light guide plate is mounted over the reflector, the optical film material is mounted over the light guide plate, the plastic frame is arranged on the backboard in the form of sleeving, the liquid crystal display panel is mounted on the plastic frame and located over the optical film material, the external frame is arranged on the plastic frame in the form of sleeving; a light guide through hole is arranged at a position, corresponding to the light guide plate, on the side edge of the backboard; a mounting groove is arranged on theplastic frame, the reflector is mounted in the mounting groove in the form of corresponding to a position of the light guide through hole; the heat dissipation mechanism comprises a heat dissipationblock and a plurality of mounting columns, the heat dissipation block is mounted in the mounting groove and located under the retroreflector, the heat dissipation block is provided with a heat dissipation slot opening downwards, and the mounting columns are mounted in the heat dissipation slot; and the LED lamp is mounted over the heat dissipation block. The liquid crystal display module with theLED lamp located at outside of the backboard has the advantages of steady structure, excellent heat dissipation effect, convenience in use, and so on.

Owner:BENGBU GUOXIAN TECH CO LTD

Making method of semiconductor chip

InactiveCN106784198AReduce absorptionImprove external quantum efficiencySemiconductor devicesQuantum efficiencyIndium

The invention provides a making method of a semiconductor chip. The making method includes steps: A, making an epitaxial layer on a substrate material; B, making a conductive extension layer on the epitaxial layer, wherein the conductive extension layer is made of indium tin oxide according to an indium-tin ratio of 95:5, and coating thickness is 500-1000A; C, etching on the epitaxial layer to form corresponding crystal grain graphs, and exposing steps of a N-type GaN layer, wherein etching depth is 1-2um, and width of a cutting way is 10-30um. Size and width of a metal electrode playing a conductive role are changed to reduce absorption of light so as to achieve the objective of improving external quantum efficiency of the chip.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Optical lens, image capturing module, electronic device and driving device

InactiveCN111856710AReduce the convergence burdenReduce volumeOptical elementsOphthalmologyOptical axis

The invention relates to an optical lens, an image capturing module, an electronic device and a driving device. The optical lens sequentially comprises a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a diaphragm sequentially from an object side to an image side along an optical axis, wherein the first lens element has negative refractive power, the object side surface is a convex surface near the optical axis, and the image side surface is a concave surface near the optical axis; the second lens element has negative refractive power, and the image side surface is a concave surface near the optical axis; the third lens element has positive refractive power; the fourth lens element has refractive power;the fifth lens element has positive refractive power, and the object side surface is a convex surface near the optical axis; the sixth lens element has negative refractive power, and the image side surface is a convex surface near the optical axis; the sixth lens element and the fifth lens element are glued; the diaphragm is arranged on the object side of the first lens element or between the first lens element and the sixth lens element, and the object side face and / or the image side face of at least one of the first lens element to the sixth lens element are / is aspheric. The optical lens canbe balanced in the aspects of expanding the field angle range, ensuring high imaging performance and realizing miniaturization when meeting a specific relation.

Owner:TIANJIN OFILM OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com