Graphical sapphire substrate and light emitting diode

A technology of patterned sapphire and light-emitting diodes, which is applied to electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

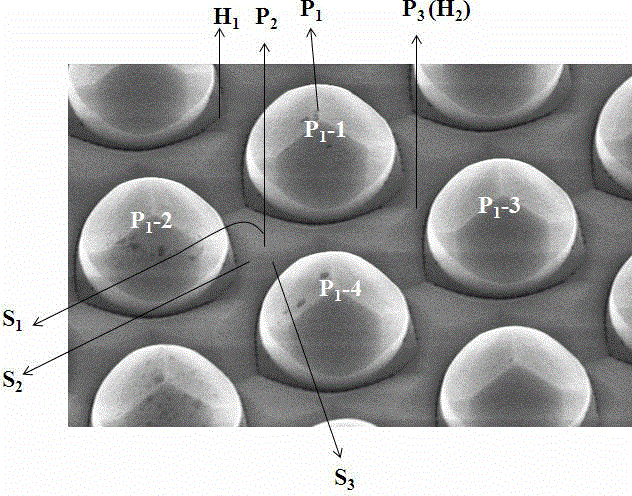

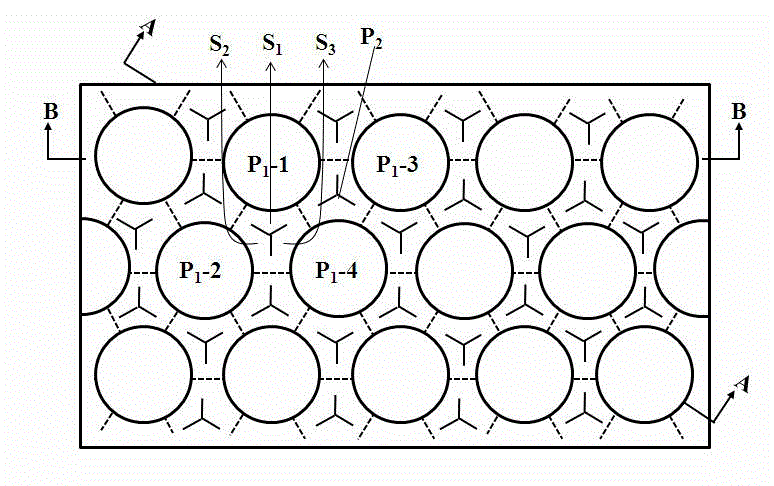

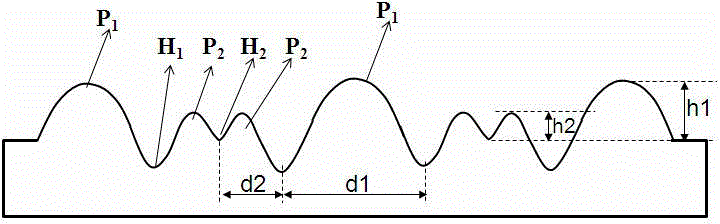

[0042] attached Figure 1~4 A preferred embodiment of the invention is shown, where image 3 is along figure 2 Cross-sectional view cut along the midline A-A, Figure 4 is along figure 2 Sectional view cut along the midline B-B.

[0043] Please see attached figure 1 and figure 2 , a patterned sapphire substrate, the upper surface of which is composed of a pattern structure, and there is no C-plane at all. The pattern structure includes a series of regularly arranged first protrusions P of the first size d1 1 , where the adjacent three first protrusions P 1 -1 、 P 1 -2 and P 1 -4 forms a triangle or a similar triangle, which has a second protrusion P with a second size d2 inside 2 , the adjacent four first protrusions P 1 -1、 P 1 -2, P 1 -3 and P 1 A rhombus is formed between -4, wherein there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com