Method for manufacturing patterned sapphire substrate

A technology for patterning sapphire and sapphire substrates, which is applied to electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

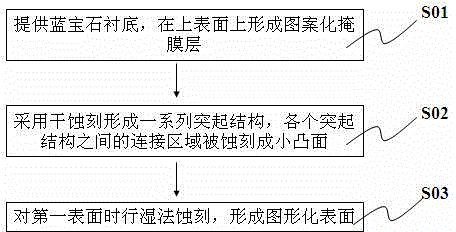

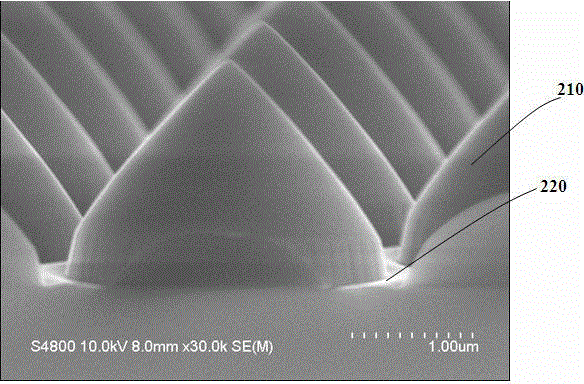

[0031] figure 1 Disclosed is a method for fabricating a patterned sapphire substrate, comprising steps S01 to S03, including forming a photomask layer, etching the substrate surface by dry etching, and forming a patterned surface without c-plane by wet etching the substrate surface .

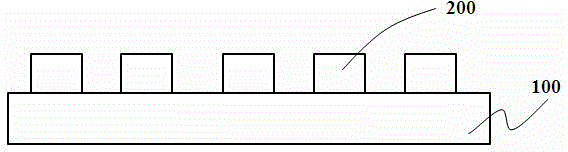

[0032] Step S01: Provide a sapphire substrate having opposite first and second surfaces, and form a patterned mask layer 200 on the first surface, such as figure 2 shown. The details are as follows: First, a layer of photoresist is coated on a flat sapphire substrate, and the thickness of the photoresist can be 0.5um to 3um; next, a pattern composed of a series of columnar photoresist is produced by using a yellow light process. This process can be Using a stepper exposure machine, contact exposure machine, projection exposure mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com