Dual-pattern LED patterned substrate and LED chip

A patterned substrate and double-pattern technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of reducing the space for improving the LED light extraction rate of the patterned substrate, unfavorable nucleation and growth of epitaxial GaN crystals, and single pattern rules Problems such as permanent arrangement, to achieve the effect of weakening the side luminous flux, improving LED light output efficiency, and reducing the ratio of side luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

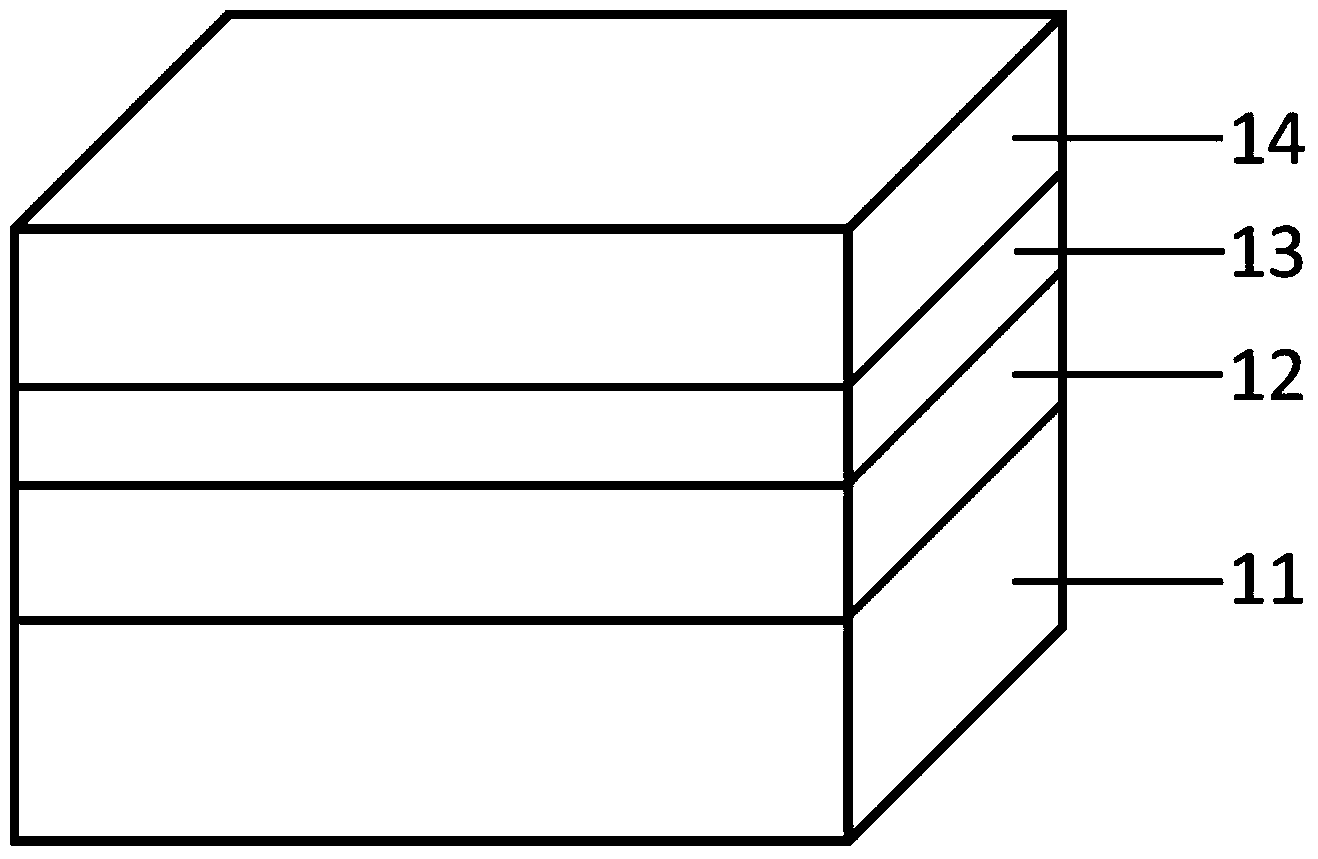

[0027] Such as figure 1 As shown, the LED chip of this embodiment is composed of a double-patterned LED patterned substrate 11 , an N-type GaN layer 12 , an MQW quantum well layer 13 , and a P-type GaN layer 14 .

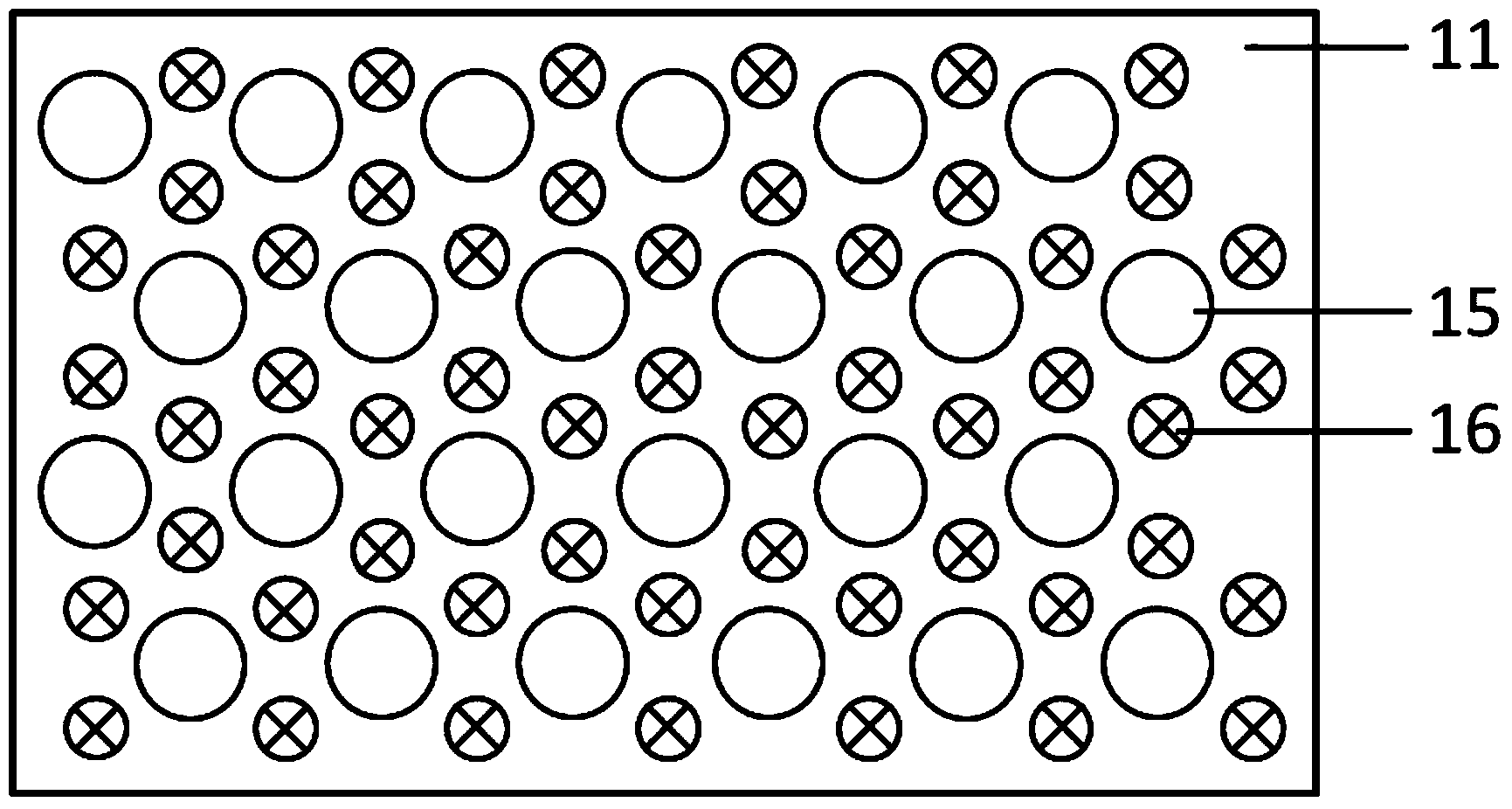

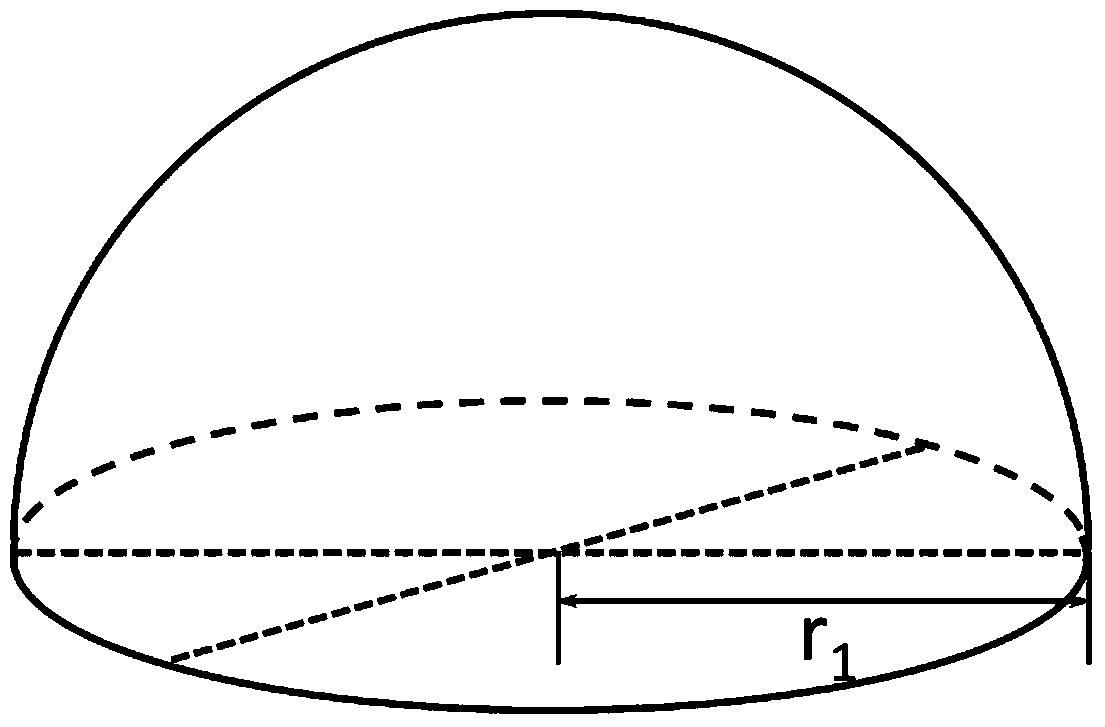

[0028] The double-patterned LED patterned substrate of this embodiment is as figure 2 As shown, the pattern on the substrate is composed of a hemispherical pattern 15 and a conical pattern 16 arranged on the substrate surface, and the radius of the bottom circle of the hemispherical pattern is r 1 is 1.0 μm, the distance d between adjacent hemispherical patterns is 3.0 μm, and the arrangement is hexagonal; the radius of the bottom circle of the conical pattern is r 2 0.4μm, inclination α 2 55°, arranged in the gap of the hemispherical pattern. Among them, the schematic diagram of the hemisphere pattern monomer is shown in image 3 , the schematic diagram of the cone pattern monomer is shown in Figure 4 .

[0029] The double-patterned LED patterned substrate ...

Embodiment 2

[0048] The LED chip of this embodiment is composed of a double-patterned LED patterned substrate, an N-type GaN layer, an MQW quantum well layer, and a P-type GaN layer arranged in sequence.

[0049] The pattern on the double-patterned LED patterned substrate of this embodiment consists of a hemispherical pattern and a conical pattern arranged on the surface of the substrate. The radius of the bottom circle of the hemispherical pattern is 1.0 μm, the distance between adjacent hemispherical patterns is 3.0 μm, and the arrangement is hexagonal; in the gap.

[0050] The double-patterned LED patterned substrate of the present embodiment is simulated and tested:

[0051] The optical analysis software TracePro is used to perform a simulation test on the patterned substrate of the LED chip of this embodiment. The simulation test process is as follows:

[0052] (1) Substrate construction: The modeling function of TracePro is used to realize the fabrication of the substrate. The size...

Embodiment 3

[0064] The LED chip of this embodiment is composed of a double-patterned LED patterned substrate, an N-type GaN layer, an MQW quantum well layer, and a P-type GaN layer arranged in sequence.

[0065] The double-patterned LED patterned substrate of this embodiment is as Figure 5 As shown, the pattern on the substrate 21 is composed of a hemispherical pattern 25 and a conical pattern 26 arranged on the substrate surface, and the radius of the bottom circle of the conical pattern is r 2 1.0μm, inclination α 3 is 55°, the distance d between adjacent conical patterns is 3.0 μm, and the arrangement is rectangular; the radius of the bottom circle of the hemispherical pattern is r 1 0.4 μm, arranged in the gap of the cone pattern.

[0066] The double-patterned LED patterned substrate of the present embodiment is simulated and tested:

[0067] Adopt optical analysis software TracePro to do simulation test to the patterned substrate of LED chip of the present invention, simulation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com