Making method of semiconductor chip

A manufacturing method and semiconductor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of low external quantum efficiency of GaN-based LEDs, and achieve the effects of easy mass production, improved quantum efficiency, and improved luminous brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

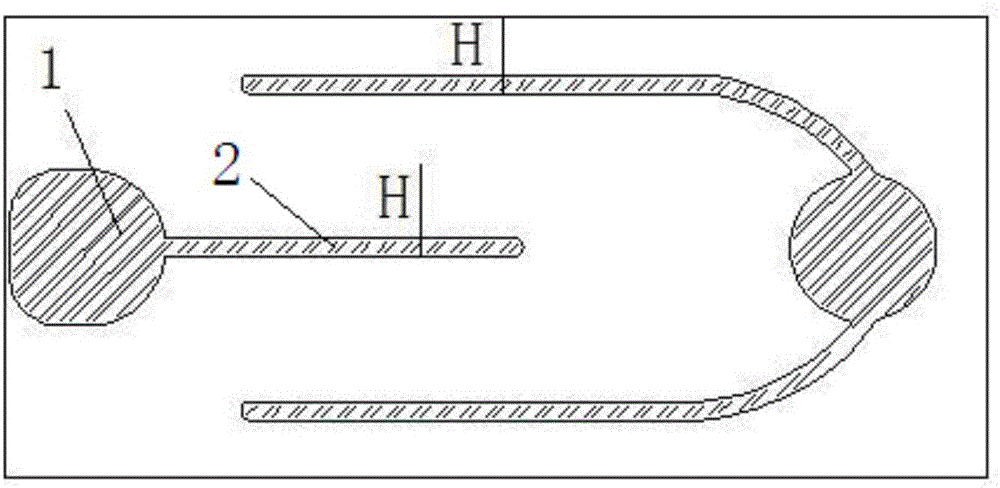

[0032] Grow a GaN epitaxial layer on a sapphire substrate, the thickness of the epitaxial layer is 6μm, and use an electron beam evaporation machine to evaporate a layer Thick ITO conductive expansion layer, followed by photolithography process to expose excess conductive expansion layer, with FeCl 3 Wet-etch the exposed conductive extension layer with a mixed solution of HCl, etch the epitaxial wafer with an ICP etching machine to expose the steps and the N-type GaN layer, the etching depth is 1.3-1.5 μm, and make a P-type electrode on the conductive extension layer , N-type electrode 1 is made on N-type GaN, the width H of N-type electrode line 2 is 10 μm, and then SiO is deposited by PECVD 2 Make a passivation layer, then test the adhesion between the metal electrode and the conductive extension layer, and then complete the post-processing steps such as wafer thinning, back-plating reflective layer, cutting slivers, point measurement and sorting, etc. The luminous brightn...

Embodiment 2

[0034] Grow a GaN epitaxial layer on a sapphire substrate, the thickness of the epitaxial layer is 6μm, and use an electron beam evaporation machine to evaporate a layer Thick ITO conductive expansion layer, followed by photolithography process to expose excess conductive expansion layer, with FeCl 3 Wet-etch the exposed conductive extension layer with a mixed solution of HCl, etch the epitaxial wafer with an ICP etching machine to expose the steps and the N-type GaN layer, the etching depth is 1.3-1.5 μm, and make a P-type electrode on the conductive extension layer , make N-type electrodes on N-type GaN, the electrode line width is 7μm, and then use PECVD to deposit SiO 2 Make a passivation layer, then test the adhesion between the metal electrode and the conductive extension layer, and then complete the post-processing steps such as wafer thinning, back-plating reflective layer, cutting slivers, point measurement and sorting, etc. The luminous brightness of the 150mA test...

Embodiment 3

[0036] Grow a GaN epitaxial layer on a sapphire substrate, the thickness of the epitaxial layer is 6μm, and use an electron beam evaporation machine to evaporate a layer Thick ITO conductive expansion layer, followed by photolithography process to expose excess conductive expansion layer, with FeCl 3 Wet-etch the exposed conductive extension layer with a mixed solution of HCl, etch the epitaxial wafer with an ICP etching machine to expose the steps and the N-type GaN layer, the etching depth is 1.3-1.5 μm, and make a P-type electrode on the conductive extension layer , make N-type electrodes on N-type GaN, the electrode line width is 5 μm, and then use PECVD to deposit SiO 2 Make a passivation layer, then test the adhesion between the metal electrode and the conductive extension layer, and then complete the post-processing steps such as wafer thinning, back-plating reflective layer, cutting slivers, point measurement and sorting, etc. The luminous brightness of the 150mA tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com