Light emitting diode (LED) lamp lens

An LED lamp lens and lens technology, which is applied to lighting devices, light sources, components of lighting devices, etc., can solve the problems of light glare, high concentration, and light glare of LED light sources, so as to reduce the price of lamps, uniform light distribution, and save materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

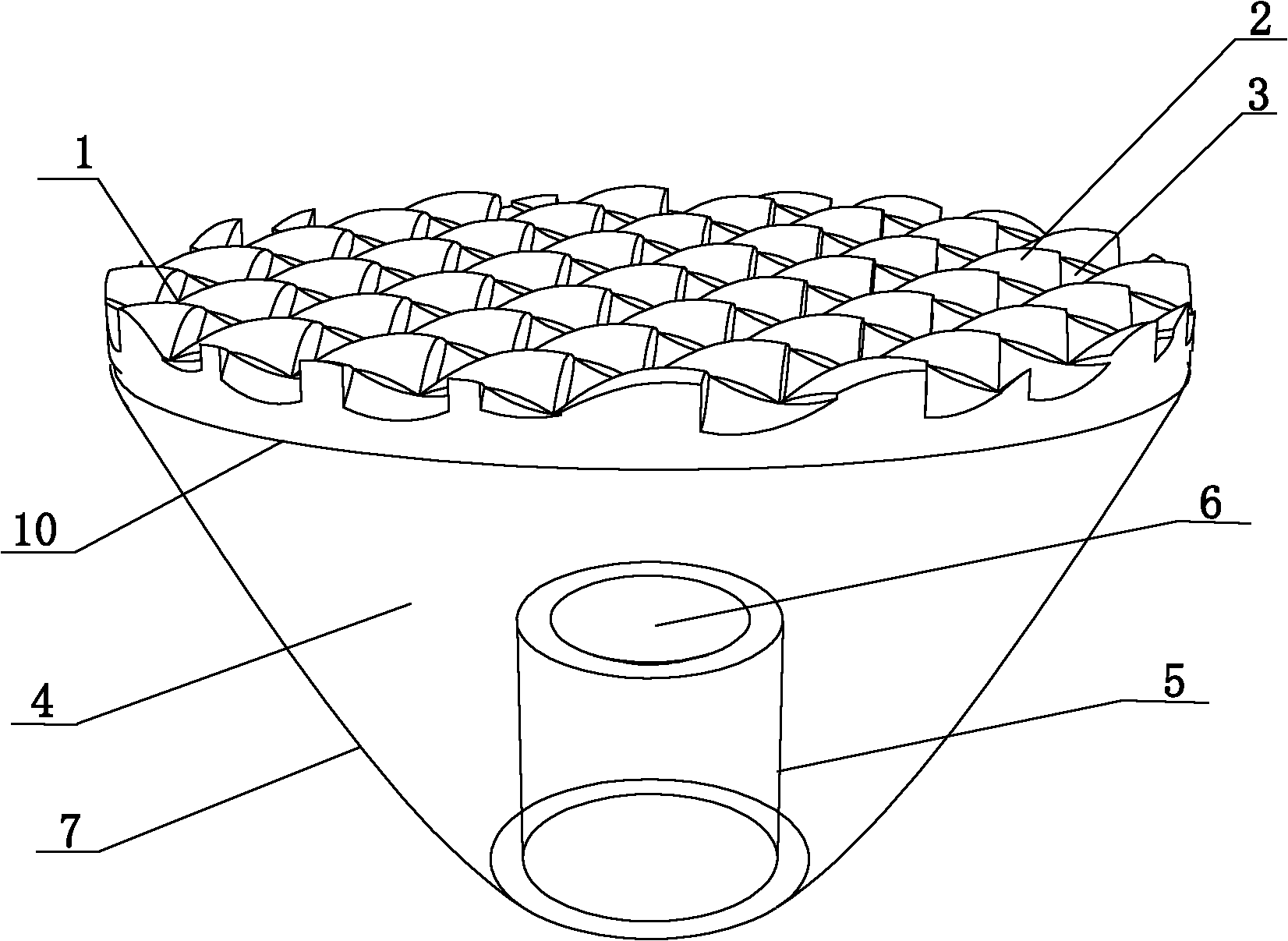

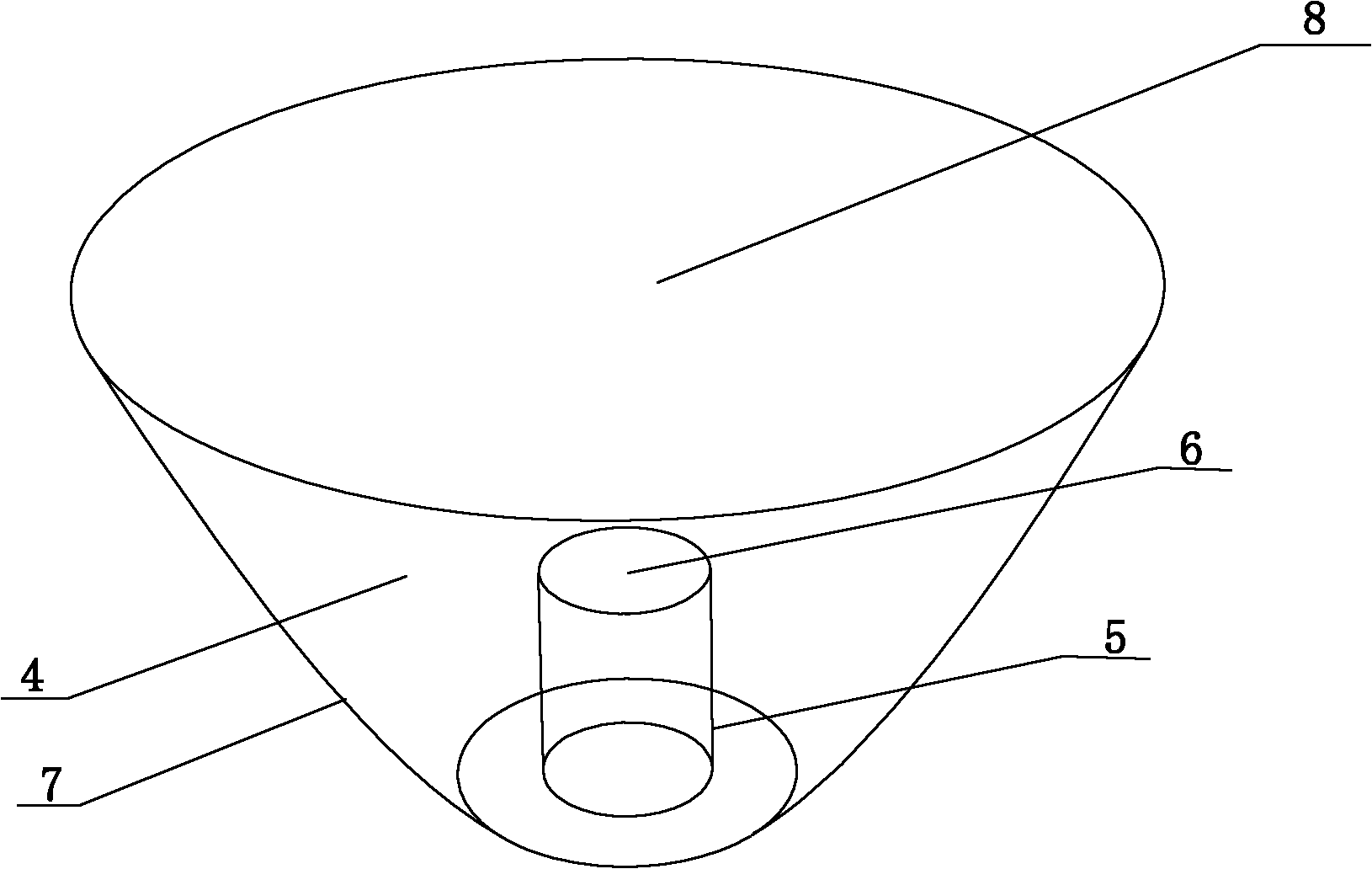

[0044] like figure 1 , figure 2 Shown, be the LED lamp lens of the present invention, comprise the collimating lens 4 of conical frustum shape or approximately frustum of conical shape; The collimating lens 4 is provided with a refraction groove 5 on one end surface opposite to the light-emitting surface 8 of the collimating lens 4;

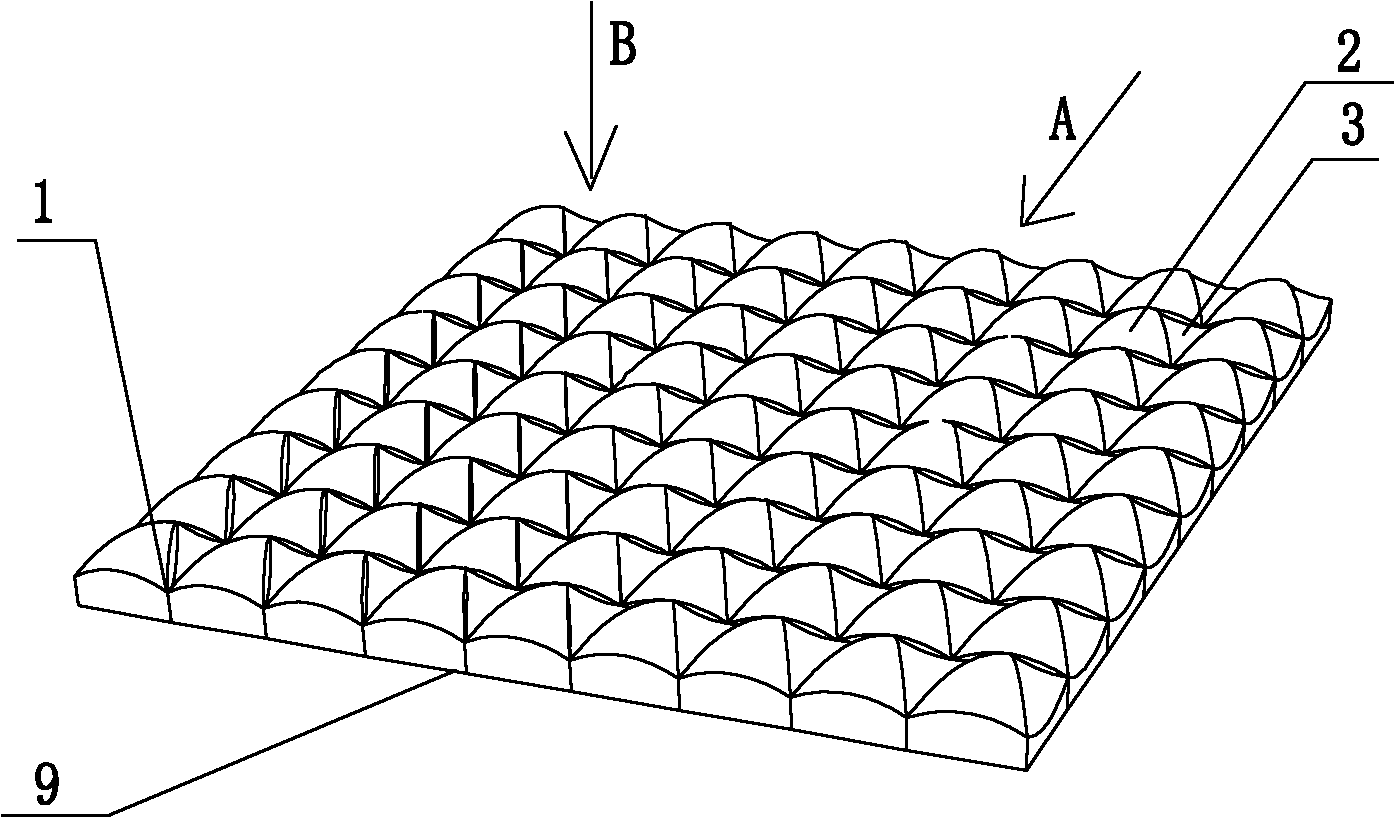

[0045] like image 3 , Figure 4 , Figure 5 As shown, the incident surface 9 of the thin-plate lens 1 is a smooth plane, and the light-emitting surface of the thin-plate lens 1 is composed of the convex surfaces of several triangular convex microlenses 2 of the same size and the concave surfaces of several triangular concave concave microlenses 3 of the same size; The convex surface of the triangular convex microlens 2 and the concave surface of the triangular concave microlens 3 face away from the light emitting surface 8 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com