A kind of anti-corrosion absorbing coating and preparation method thereof

A wave-absorbing coating and anti-corrosion technology, applied in anti-corrosion coatings, coatings, radiation-absorbing coatings, etc., can solve problems such as insufficient corrosion resistance, and achieve the effect of improving poor corrosion resistance, good compatibility, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

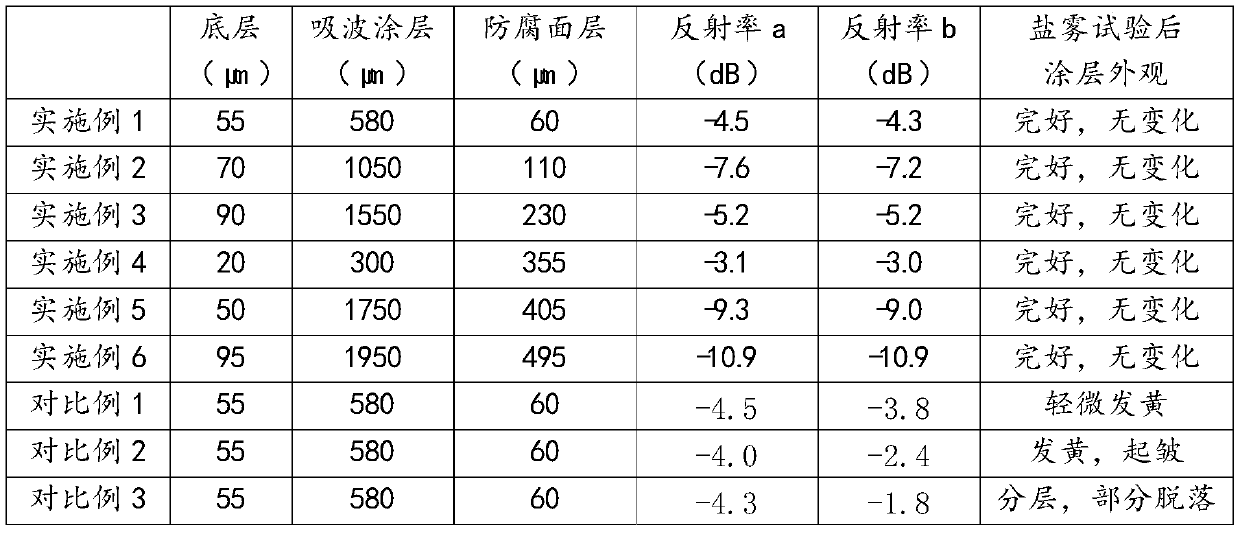

Examples

preparation example Construction

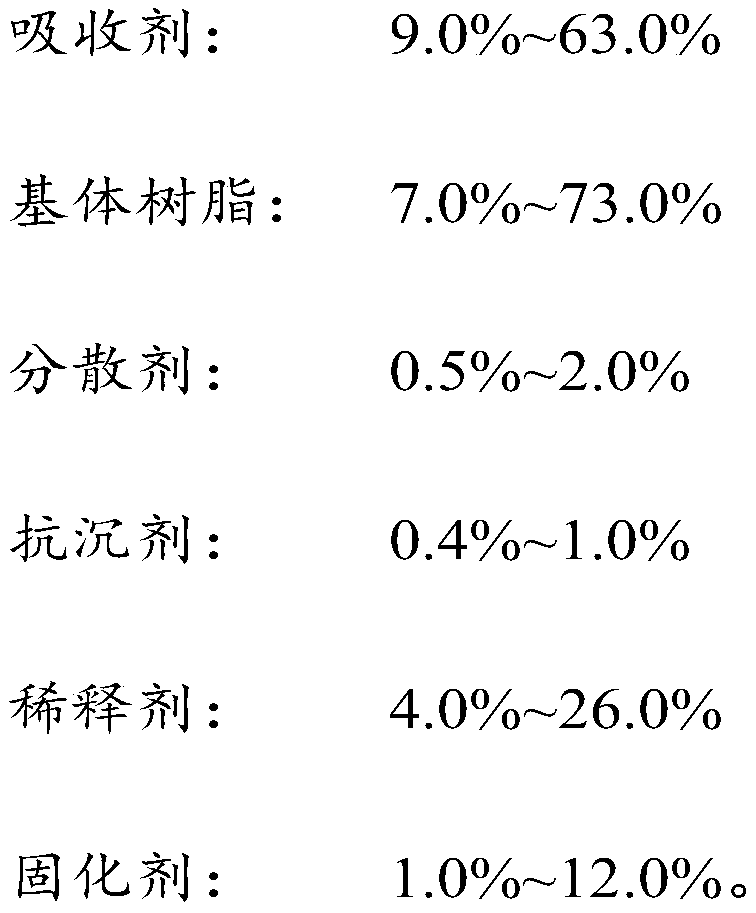

[0025] Further, the preparation method of the wave-absorbing coating comprises:

[0026] Mix the matrix resin, dispersant, anti-sedimentation agent and diluent according to the mass percentage, stir at a speed of 1000-1200rmp for 20-40min, then add the absorbent, continue stirring for 20-40min, then add the curing agent, Stir for 3 to 10 minutes.

[0027] The wave-absorbing layer prepared by the above method uses prepolymer polyurethane resin and amine curing agent to react to form polyurea. The coating has high crosslinking degree, good mechanical properties, good compatibility with various electromagnetic wave absorbers, and can meet the requirements of It can meet the requirements of high filling amount of agent, and realize the wide adjustment of different absorbing performance requirements.

[0028] Further, the acrylic polyurethane bottom layer is formed by spraying an acrylic polyurethane coating on the surface of the substrate. Preferably, the coating thickness is 20-...

Embodiment 1

[0037] This embodiment provides an anti-corrosion wave-absorbing coating, the preparation method of which comprises:

[0038] Coating preparation on a 180mm×180mm×5mm aluminum alloy substrate:

[0039]First, use a pneumatic grinder to grind the surface of the base plate with 80-grit sandpaper until a rough frosted texture appears, then wipe the surface with a cotton cloth dipped in acetone to remove surface impurities and oil, and dry it. Then spray an acrylic polyurethane primer with a thickness of 55 μm and cure for 12 hours at room temperature to form an acrylic polyurethane bottom layer; then spray a wave-absorbing coating with a thickness of 580 μm and cure for 24 hours at room temperature to form a wave-absorbing layer; finally spray a solvent-free polyurethane coating to form an anti-corrosion surface layer , with a thickness of 60 μm, after 12 hours of curing at room temperature, the anti-corrosion and wave-absorbing coating is obtained.

[0040] The preparation metho...

Embodiment 2

[0043] This embodiment provides an anti-corrosion wave-absorbing coating, the preparation method of which comprises:

[0044] Coating preparation on a 300mm×300mm×5mm aluminum alloy substrate:

[0045] First, use a pneumatic grinder to grind the surface with 120-grit sandpaper until a rough frosted texture appears, then wipe the surface with a cotton cloth dipped in alcohol to remove surface impurities and oil, and then dry it. Then spray acrylic polyurethane primer with a thickness of 70 μm and cure at room temperature for 12 hours to form an acrylic polyurethane bottom layer; then spray a wave-absorbing coating with a thickness of 1050 μm and cure at room temperature for 24 hours to form a wave-absorbing layer; finally spray a solvent-free polyurethane coating to form an anti-corrosion surface layer , thickness 110μm, curing at room temperature for 12 hours, that is, anti-corrosion absorbing coating.

[0046] The preparation method of the wave-absorbing coating described th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com