Light emitting diode (LED) lamp optical lens

A light optics and lens technology, applied in the field of LED lighting equipment, can solve the problems of concentrated light sources, glare, and small LED light-emitting surface, and achieve the effects of soft light, material cost saving, and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

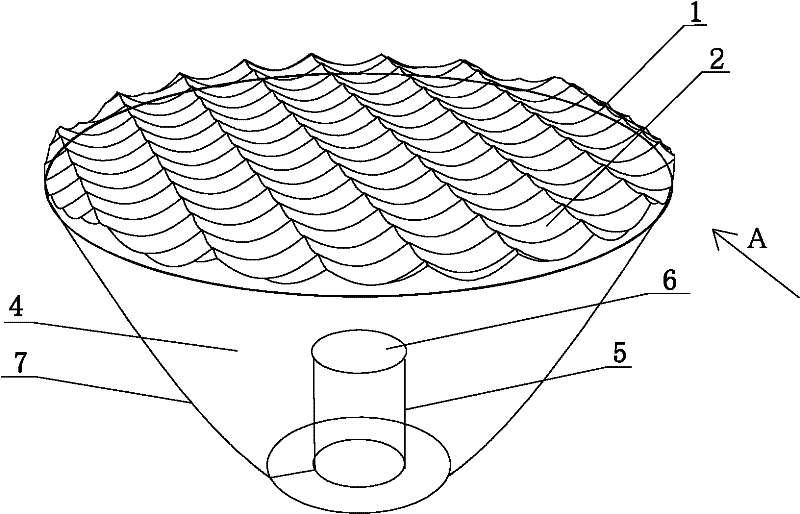

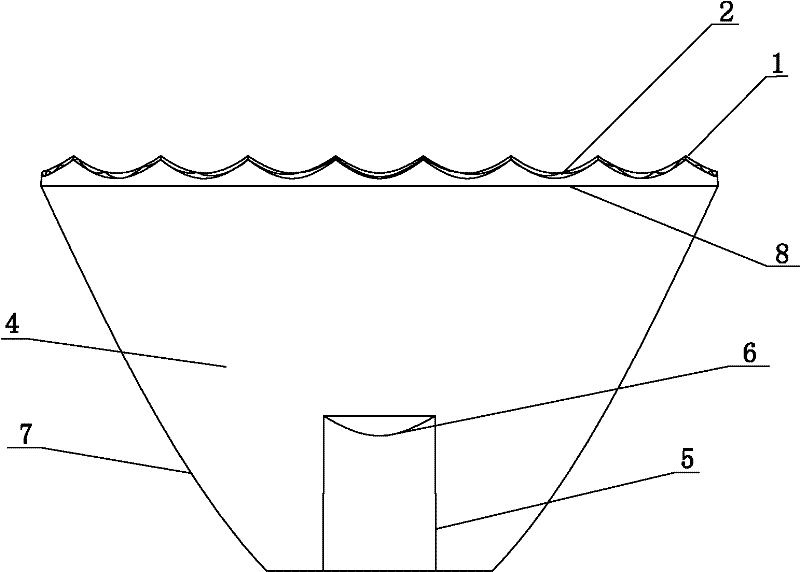

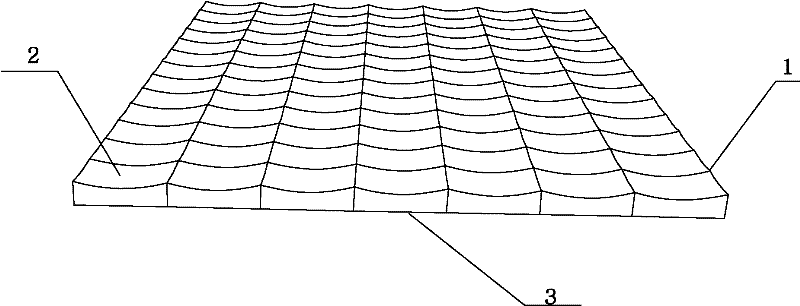

[0041] Such as figure 1 , figure 2 , image 3 Shown, is the optical lens of LED light of the present invention, comprises the collimating lens 4 of conical frustum shape or approximately frustum of conical shape; The side 7 of collimating lens 4 is a total reflection surface; The light exit surface of lens 1 is made up of the planar array that the concave surface of several rectangular concave microlenses 2 of the same size are closely arranged, and the concave surface of rectangular concave microlens 2 is facing away from the light exit surface of collimating lens 4; collimating lens 4 is in A refraction groove 5 is provided on the end surface opposite to the light-emitting surface of the collimating lens 4 ; The LED light optical lens can be obtained by integral molding, or can be obtained by combining the collimating lens 4 and the thin plate lens 1 separately. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com