Main steam temperature control system and method for thermal power plant based on event-triggered mechanism

A steam temperature, event-triggered technology, applied in control systems, steam generation, lighting and heating equipment, etc., can solve problems such as undiscovered, achieve the effect of reducing the number of adjustments, strong stability and robustness, and reducing the amplitude of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

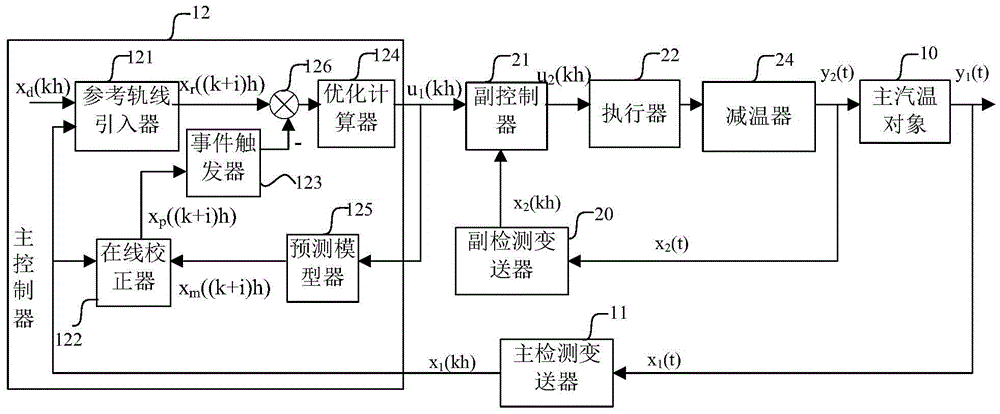

[0035] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

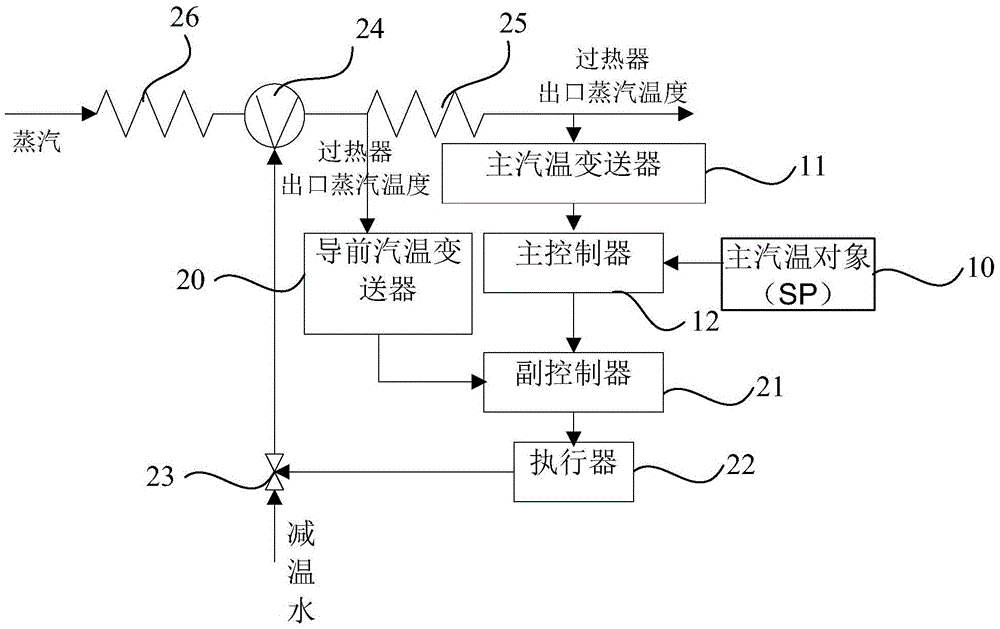

[0036] because figure 1 In the traditional control method of the main steam temperature of the thermal power plant shown, the continuous adjustment of the auxiliary controller makes the control valves and other actuators operate frequently, which reduces the service life. Therefore, in the event-triggered mechanism-based main steam temperature control system of the present invention , In the case of considering stability and safety, priority is given to reducing the number of executions of the actuator.

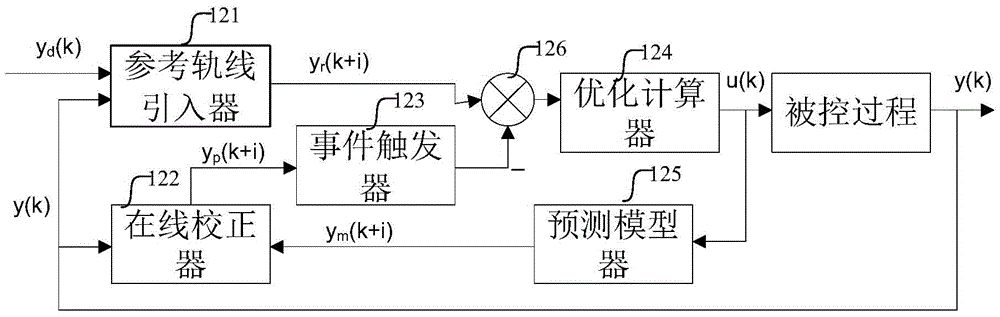

[0037] figure 2 Shown is a schematic structural diagram of a main controller with an event trigger added to the present invention based on reducing the execution times of the executor. The main controller designed by the present invention has a prediction function, which can predict the current control input and historical data of the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com