High-pressure cooling-heating table device for in-situ observation of aquo-complex microscopic reaction kinetics process and application method

A reaction kinetics, hot and cold stage technology, applied in measurement devices, scientific instruments, material analysis by optical means, etc., can solve problems such as the inability to take out the whole and the inability to truly simulate the high-pressure reaction process of hydrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

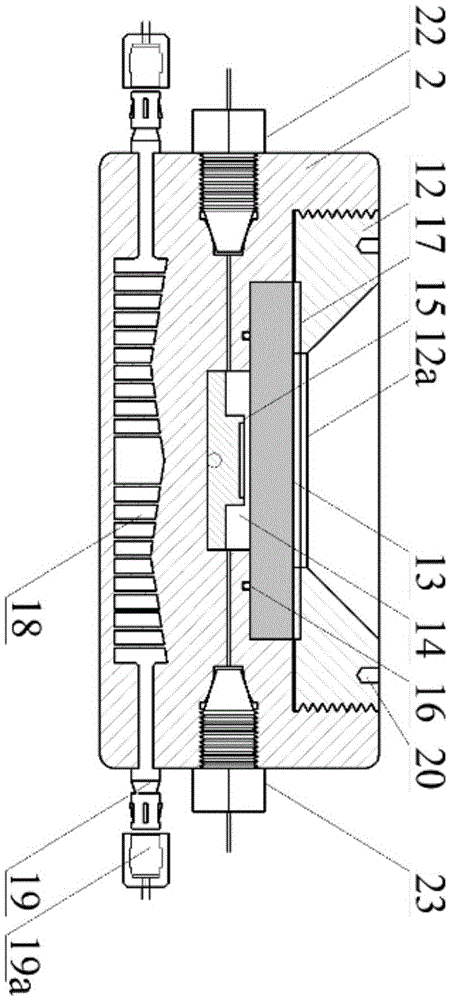

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

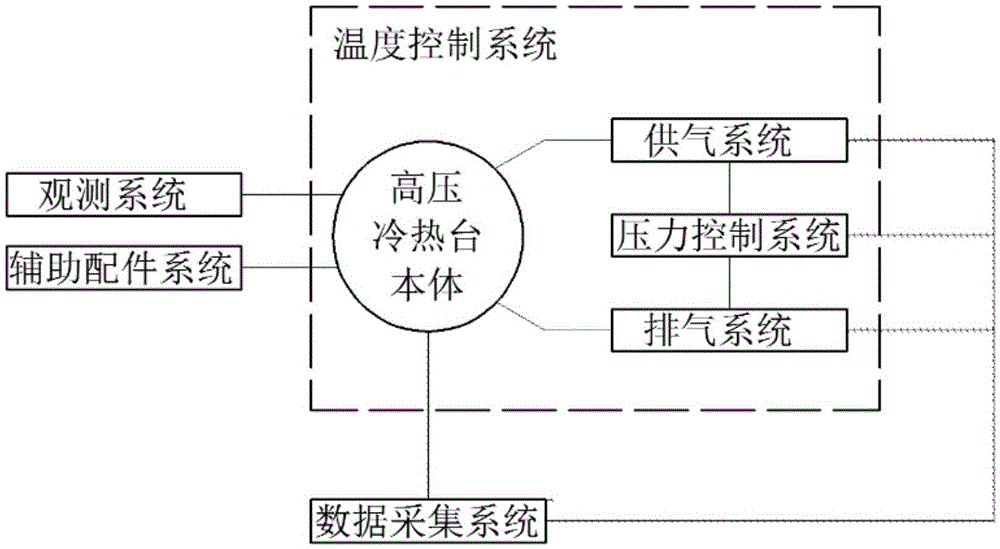

[0033] figure 1 Shown is a working principle diagram of an in-situ observation device for microscopic reaction kinetics of hydrates. The working process of the device is as follows: the device of the present invention supplies methane gas to the high-pressure cold and hot table body through the exhaust system and the gas supply system, and passes through The pressure of the two buffer tanks is constant, and the temperature required for the reaction is controlled by the constant temperature tank. The working parameters such as temperature and pressure signals during the reaction process are collected and analyzed by the computer data acquisition system.

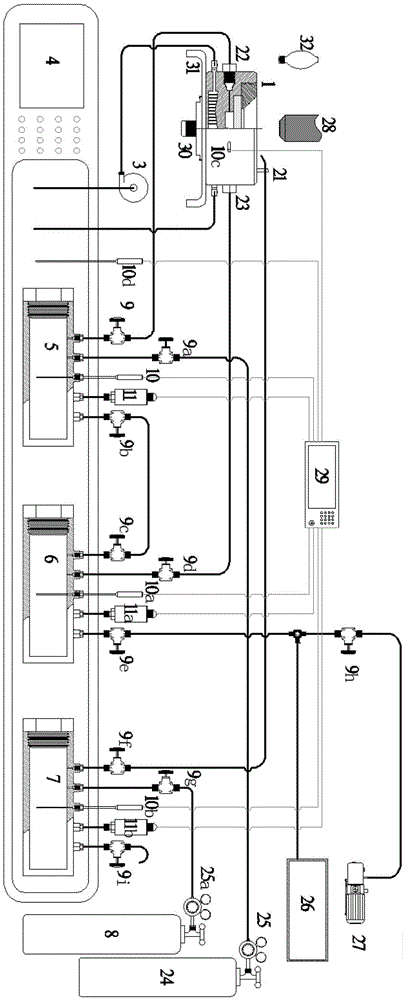

[0034] figure 2 It is a system diagram of an in-situ observation device for the microscopic reaction kinetics of hydrates. The following describes each system function:

[0035] 1. The worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com