Tower paint surface corrosion safe state evaluation method

A technology of safety state and evaluation method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large human factors, non-objectiveness, non-standard evaluation of tower coating corrosion state, etc., and achieve good repeatability, easy execution, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The method for evaluating the corrosion state of the painted surface of the pole and tower in service of the present invention includes the following steps:

[0050] Step 1: Data collection

[0051] Collect the original data and operation and maintenance data of the evaluated tower, including tower installation reports, construction records, inspection reports over the years, and anti-corrosion maintenance records.

[0052] Step 2: Build the state of corrosion evaluation

[0053] According to the collected data, determine the corrosion type of the tower and construct the corrosion evaluation status quantity.

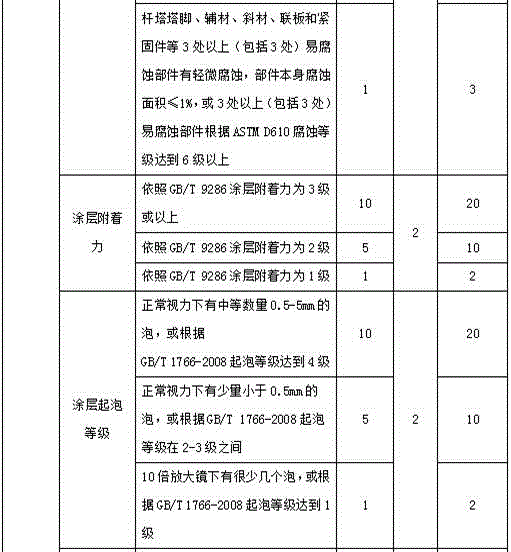

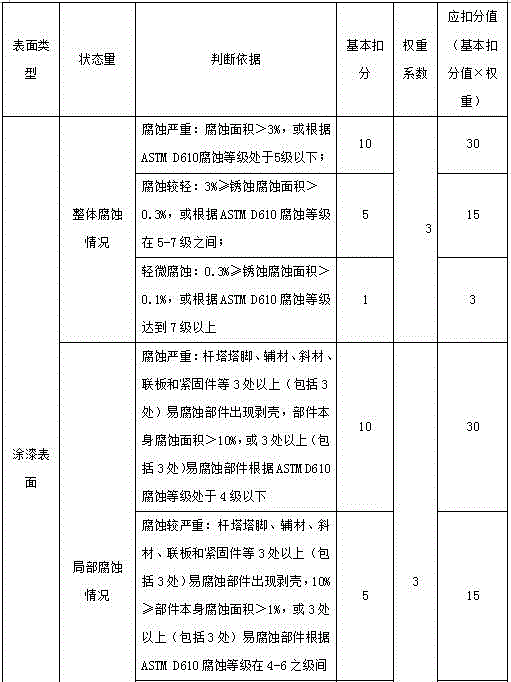

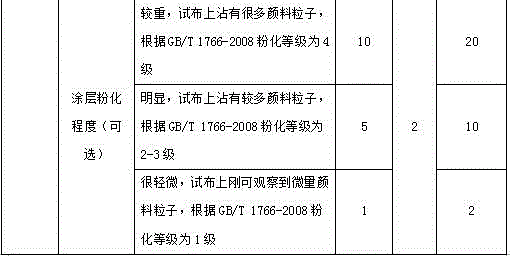

[0054] Step 3: Establish the evaluation standard of corrosion state quantity

[0055] Determine the weight of the state quantity, construct the basis for judging the deterioration degree of the state quantity, and construct the deduction algorithm for the corrosion state quantity. The specific deduction criteria for corrosion status are as follows:

[0056] Table 1 Judgment ...

Embodiment 2

[0069] In July 2012, the original data and operation and maintenance data of three 220kV lines in a mountainous area were collected. The three lines were respectively subjected to anti-corrosion maintenance in May 2007, August 2009 and September 2011. The form of anti-corrosion was painting with paint, and no maintenance was carried out in the later period. The current type of anti-corrosion of poles and towers is painted anti-corrosion.

[0070] The safety evaluation of the 6-base towers in the area was carried out using the method of Example 1; among them, 2 base towers were in a normal state, 2 base towers were in a state of attention, and 2 base towers were in a serious state.

[0071] (1) No maintenance was carried out for the poles in severe conditions. After 3 years, the 2 base poles and towers partially experienced severe corrosion and thinning.

[0072] (2) Anti-corrosion maintenance is not carried out for the poles in the state of attention. After 3 years, they are evaluate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com