Conductivity sensor and manufacture method thereof

A conductivity sensor and manufacturing method technology, applied in the direction of fluid resistance measurement, etc., can solve the problems of multi-specialized production equipment, complex production process, high production cost, etc., and achieve the effects of low cost, reduced flow resistance, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

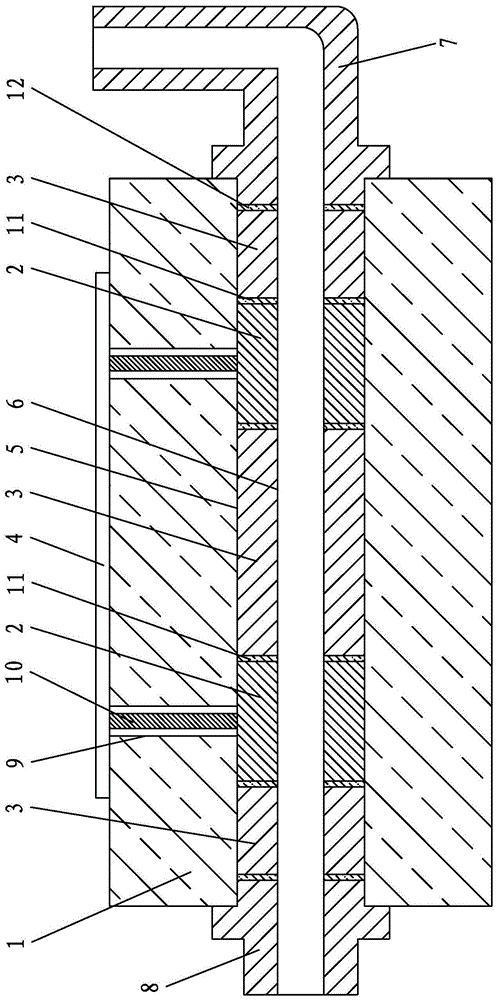

[0025] Such as figure 1 As shown, the conductivity sensor of the present invention includes a cylindrical insulating housing 1, an electrode 2, an insulating block 3, and a circuit board 4. The housing 1 is provided with a mounting hole 5 in the axial direction, and the cross section of the mounting hole 5 is circular or regular polygon. Three insulating blocks 3 and two electrodes 2 are arranged in the mounting hole 5 at intervals, and an annular first sealing gasket 11 is arranged between adjacent electrodes 2 and insulating blocks 3. The insulating block 3 and the electrode 2 are respectively provided with axial through holes corresponding to each other, and the axial through holes penetrate to form a flow channel 6. The two ends of the shell 1 are respectively screwed with an inlet connector 7 and an outlet connector 8. The channels in the inlet connector 7 and the outlet connector 8 communicate with the flow channel 6 in the shell 1, and the inlet connector 7 and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com