Method and system for testing battery electricity quantity

A technology of battery power and test method, applied in the field of electricity, can solve the problems of no power coulomb counter module and high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

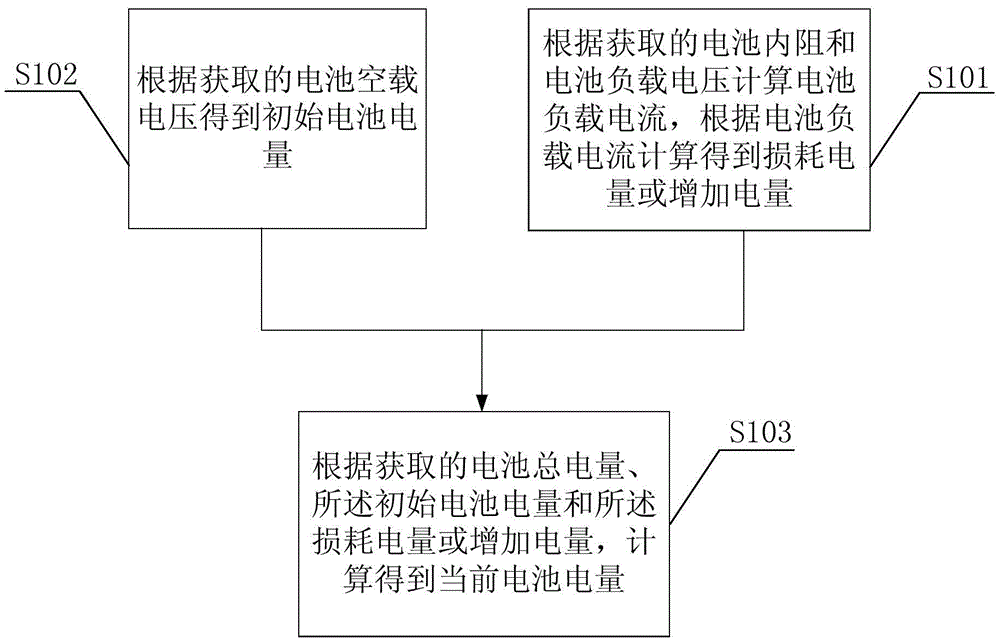

[0058] like figure 1 As shown, a method for testing battery power is disclosed in this embodiment, and the method includes:

[0059] S101. Calculate the battery load current according to the obtained battery internal resistance and the battery load voltage, and calculate the power loss or increase power according to the battery load current;

[0060] S102, obtaining the initial battery power according to the acquired battery no-load voltage;

[0061] S103. Calculate and obtain the current battery power according to the obtained total battery power, the initial battery power, and the consumed or increased power.

[0062] In this way, only the same type of battery needs to be discharged and tested to obtain relevant parameters of the battery, such as battery internal resistance, battery load voltage, battery no-load voltage, total battery power, initial battery power and other parameters, and then conduct a series of The current battery power can be obtained by calculation. Of...

Embodiment 2

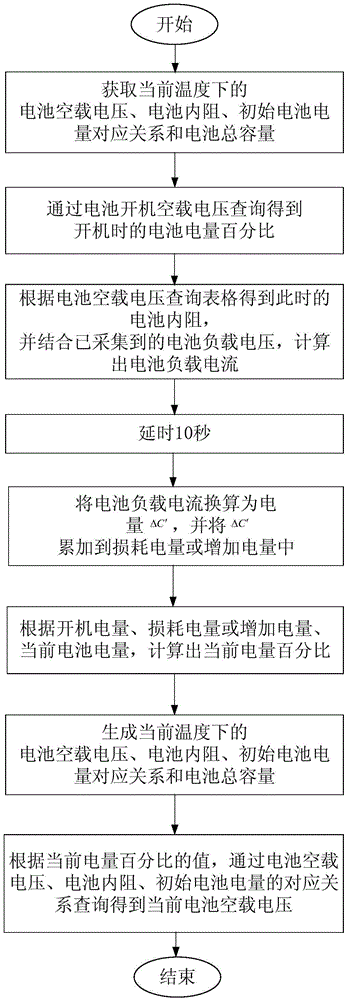

[0110] This embodiment is a further detailed description of the current power calculation in the embodiment, combined with figure 2 shown.

[0111] Step 1: According to the collected current temperature t, and the battery no-load voltage, battery internal resistance, and initial battery power (T ocv -r-c) The corresponding relationship between the three, using the linear interpolation method to dynamically calculate the battery no-load voltage corresponding to the current temperature, battery internal resistance, initial battery power (T ocv -r-c) Correspondence between the three. At the same time, according to the collected current temperature and the total battery capacity C under 5 temperatures (-20°C, -10°C, 0°C, 25°C, 50°C max(t) , dynamically calculate the total battery capacity C corresponding to the current temperature by linear interpolation method max .

[0112] Step 2: According to the collected battery power-on no-load voltage V ocv-init Inquiry form T ocv-r...

Embodiment 3

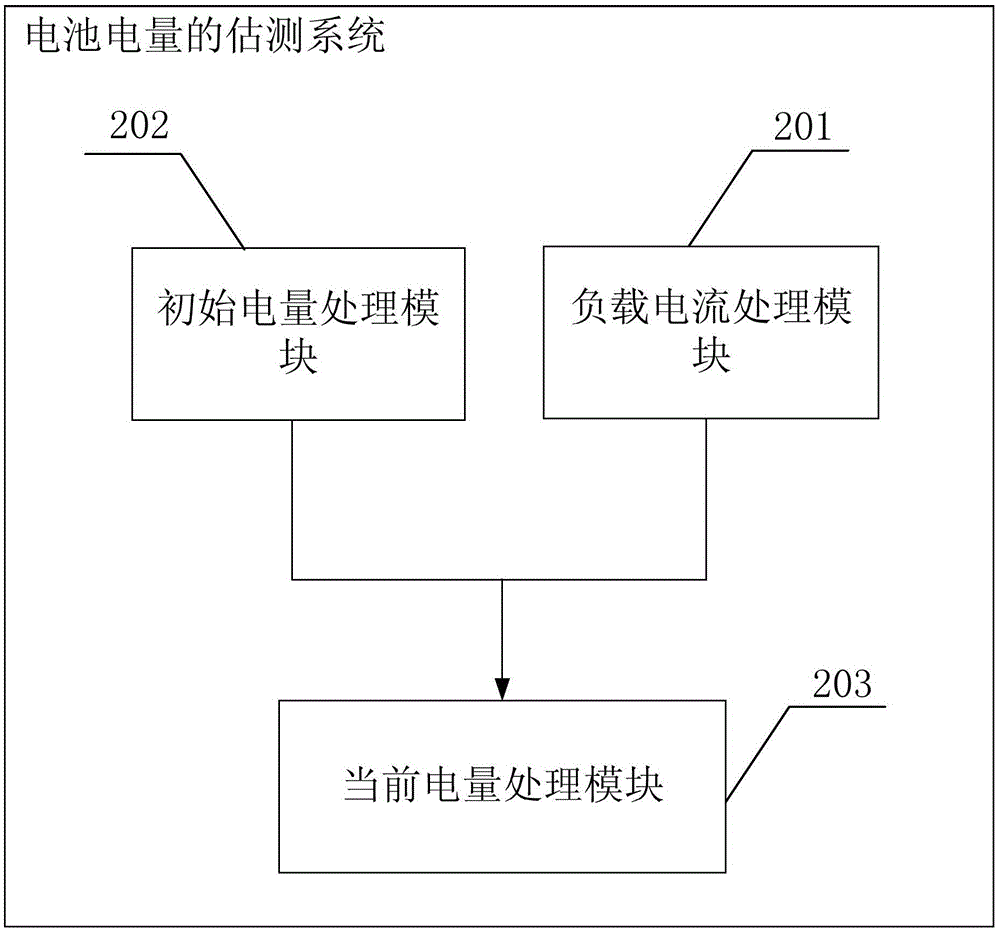

[0127] Such as image 3 As shown, this embodiment discloses a battery power test system, the system includes:

[0128] The load current processing module 201 is used to calculate the battery load current according to the obtained battery internal resistance and the battery load voltage, and calculate the power loss or increase power according to the battery load current;

[0129] An initial power processing module 202, configured to obtain the initial battery power according to the acquired battery no-load voltage;

[0130] The current power processing module 203 is configured to calculate and obtain the current battery power according to the acquired total battery power, the initial battery power, and the consumed or increased power.

[0131] In this way, only the same type of battery needs to be discharged and tested to obtain relevant parameters of the battery, such as battery internal resistance, battery load voltage, battery no-load voltage, total battery power, initial ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com