Method for analyzing hydraulic loss of centrifugal pump based on entropy theory

A theoretical analysis, centrifugal pump technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of sharp changes and deviations in temperature distribution, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

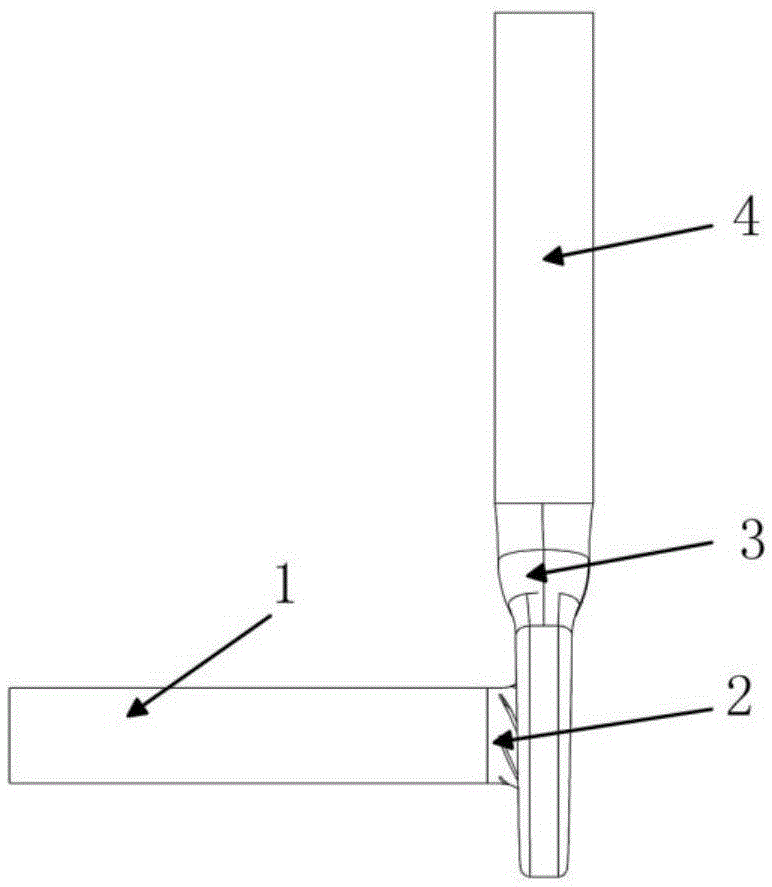

[0072] Step A) The computational domain of the centrifugal pump is modeled using Creo 3D modeling software. Such as figure 1 As shown, the calculation domain is divided into four parts: inlet pipe 1, impeller 2, volute 3 and outlet pipe 4;

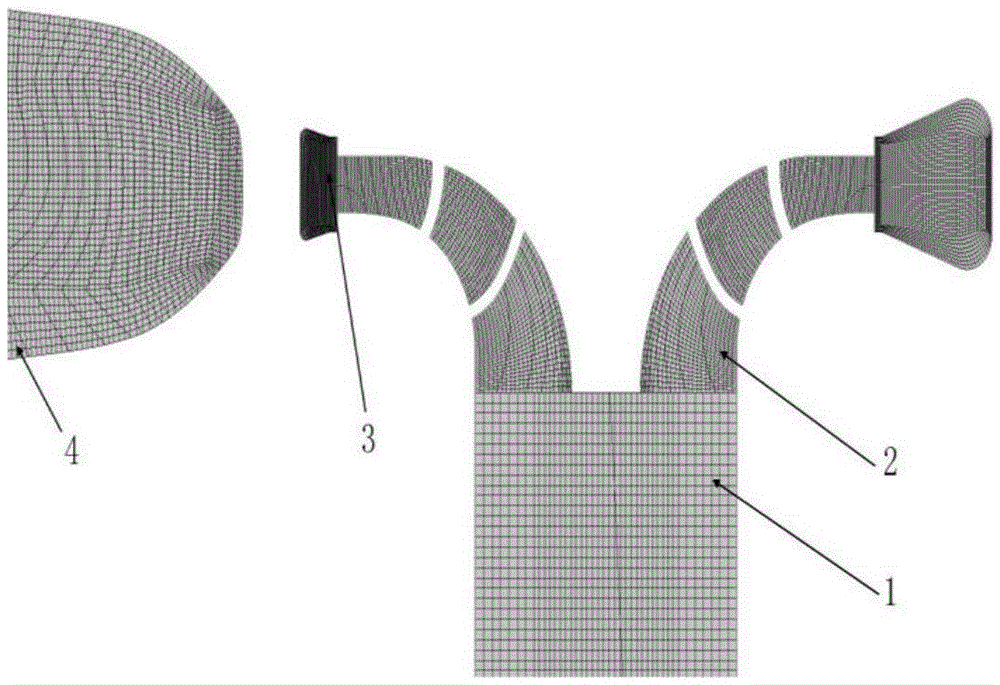

[0073] Step B) Import the calculation domain obtained in step A into ANSYS software for mesh division, such as figure 2 As shown, ICEM in ANSYS is used to divide the inlet pipe 1 and outlet pipe 4 in the computational domain into structured meshes; Meshing is used to divide the impeller 2 and volute 3 in the computational domain into unstructured meshes; at the same time, to meet the standard Wall function vs. Y + According to the requirements, the mesh of the impeller 2 wall and the volute 3 wall are encrypted, and the mesh is divided into 120W, 150W, 177W, and 200W meshes;

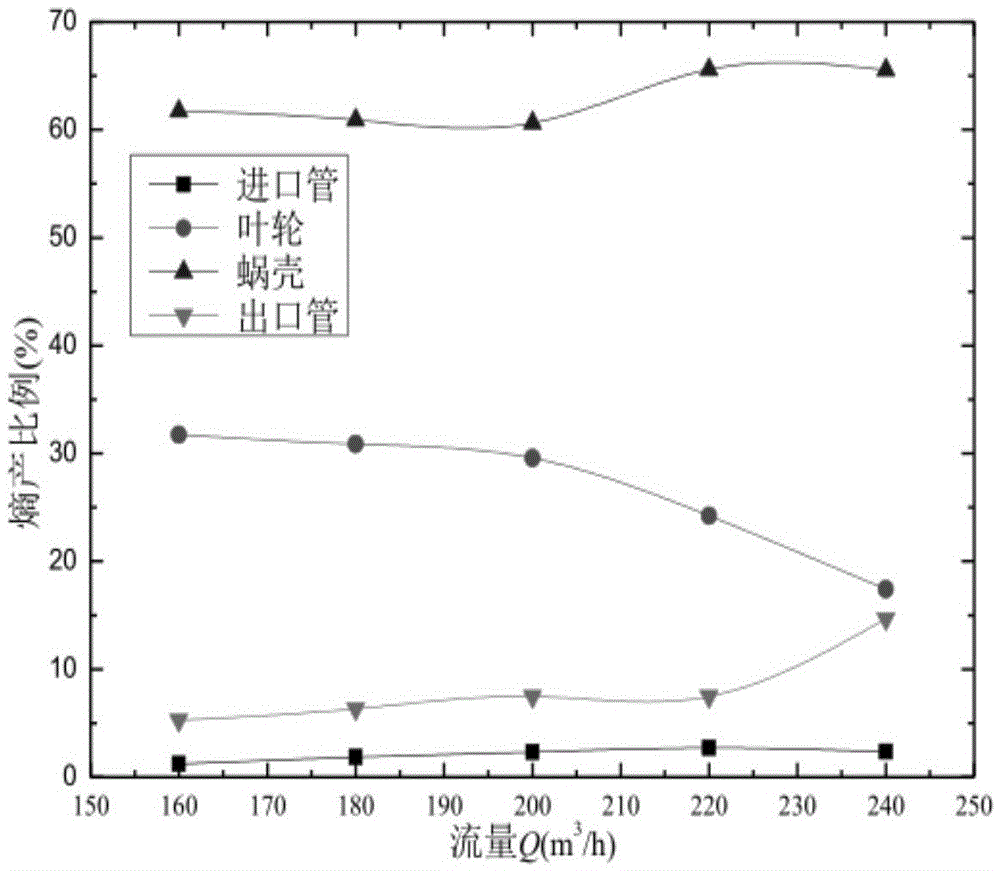

[0074] Step C) Using Fluent in ANSYS to carry out the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com