Design Method of Leaf Spring with Unequal Structure and Few Leaf Slant Lines at Ends with Variable Cross-section

A technology of leaf spring and design method, which is applied in the direction of leaf spring, spring, spring/shock absorber, etc., can solve the problem of not being able to meet the design requirements of small oblique line type variable cross-section leaf spring, it is difficult to obtain parameter design values, and it is impossible to provide Analyze issues such as design formulas to achieve the effects of improving transportation efficiency and driving safety, reducing design and test costs, and reducing quality and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

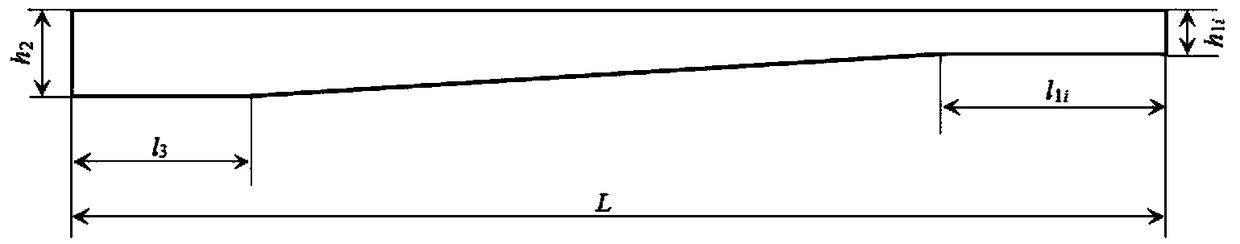

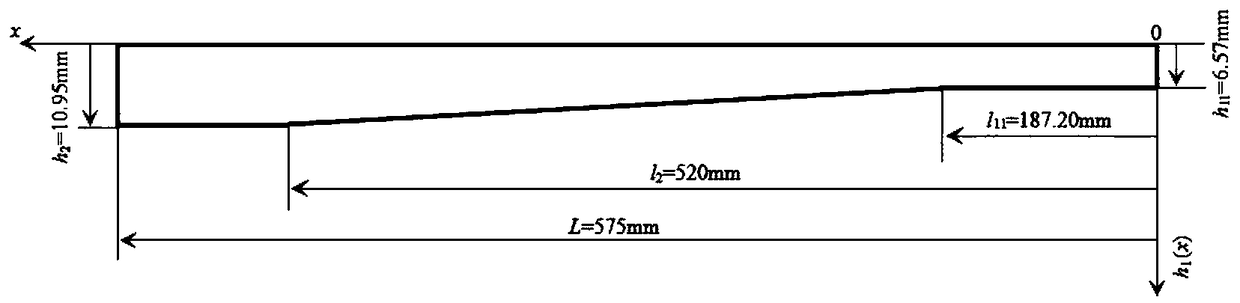

[0050] Embodiment 1: The structure schematic diagram of half of the single-leaf spring of a non-equal-structure few-piece inclined-line type variable-section leaf spring at a certain end is as follows figure 2 As shown, among them, half length L of each leaf spring = 575mm, width b = 60mm, half of the installation distance l 3 =55mm, half load P=1200N acting on the free end of the leaf spring, elastic modulus E=200GPa, safe allowable stress [σ]=500MPa. Half of the rigidity design requirement value K M =24N / mm, design the leaf spring with non-equal structure and few oblique lines at the end.

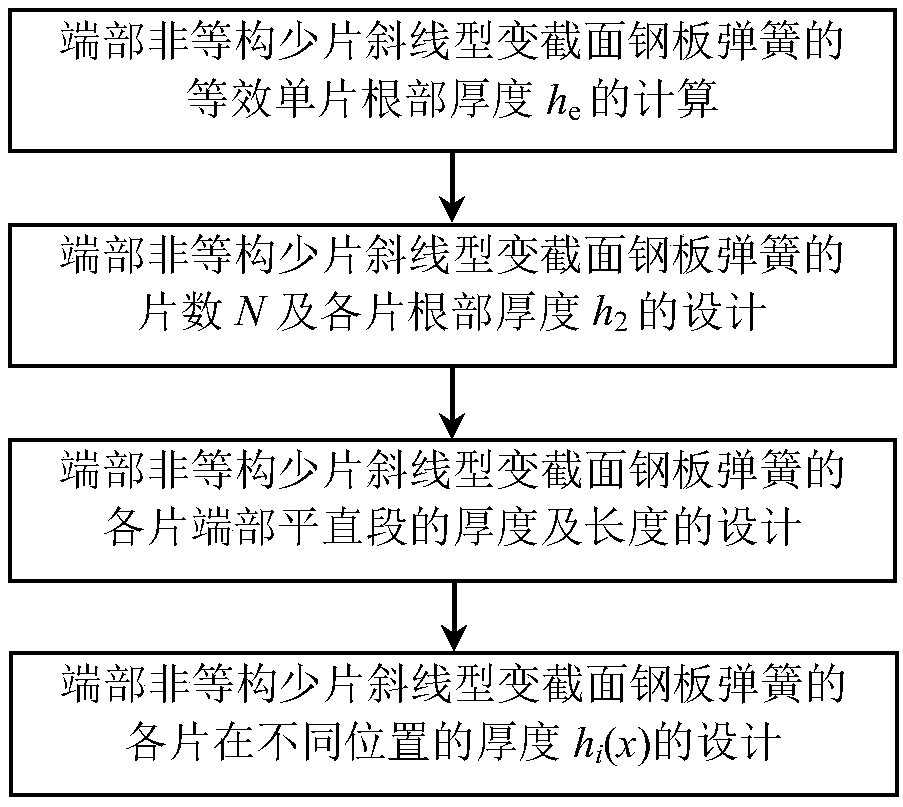

[0051] The design method of the end non-equal structure few pieces oblique line type variable section leaf spring provided by the example of the present invention, its design process is as follows figure 1 As shown, the specific steps are as follows:

[0052] (1) The equivalent root thickness h of a few-piece slash type variable-section leaf spring e The calculation of:

[0053] Fir...

Embodiment 2

[0086] Embodiment 2: The structure schematic diagram of half of the single-leaf spring of a non-equal-structure few-piece inclined-line type variable-section leaf spring at a certain end is as follows figure 2 As shown, among them, half length L of each leaf spring = 600mm, width b = 60mm, half of the installation distance l 3 =60mm, half load P=3000N acting on the free end of the leaf spring, elastic modulus E=200GPa, safe allowable stress [σ]=500MPa. Half of the rigidity design requirement value K M =46N / mm, design the leaf spring with non-equal structure and few oblique lines at the end.

[0087] The design method of the end non-equal structure few pieces oblique line type variable section leaf spring provided by the example of the present invention, its design process is as follows figure 1 As shown, the specific steps are as follows:

[0088] (1) The equivalent root thickness h of a few-piece slash type variable-section leaf spring e The calculation of:

[0089] Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com