Design method of leaf spring with few pieces and variable cross-section based on vehicle parameters

A technology of leaf springs and vehicle parameters, which is applied to vehicle components, calculations, elastic suspensions, etc., can solve the problem of unsatisfactory, unsatisfied design requirements of leaf springs with few pieces of variable cross-section, and design requirements of small leaf springs with variable cross-section, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: The sprung mass m=375.26kg of the single-wheel suspension of a certain vehicle, the natural frequency design value f of the suspension system s=1.8Hz, wherein, the length L of half of the leaf spring with a small variable section of the vehicle = 575mm, the width b = 60mm, and half of the installation distance l 3 =55mm, elastic modulus E=200GPa, safe allowable stress [σ]=500MPa. The leaf spring with few pieces of variable cross-section is designed for this vehicle.

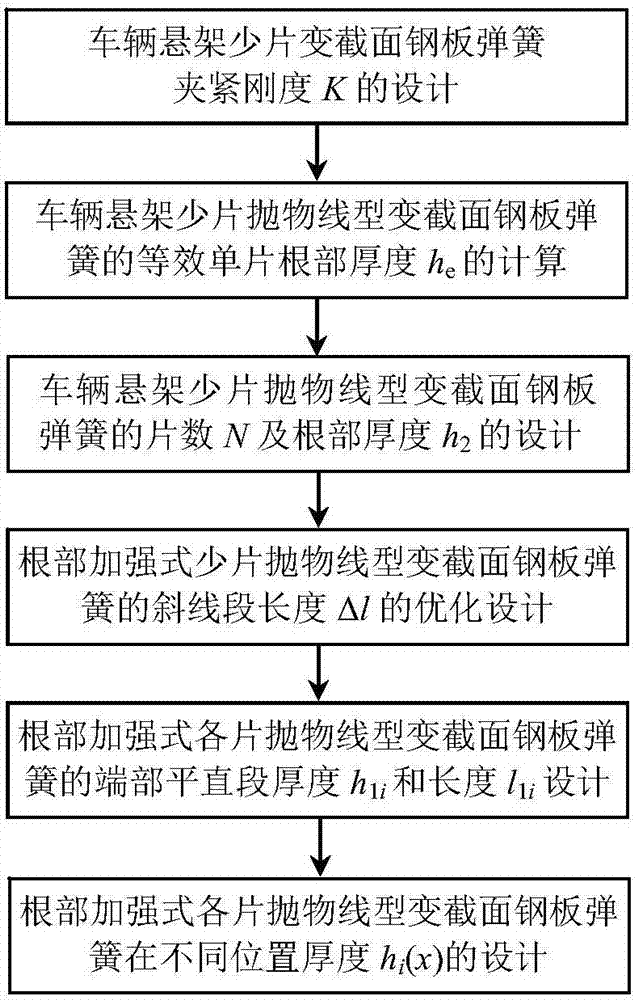

[0069] The design method of the few sheet variable section leaf springs based on vehicle parameters provided by the example of the present invention, its design process is as follows figure 1 As shown, the specific steps are as follows:

[0070] (1) The clamping stiffness K design of the vehicle suspension with few parabolic variable-section leaf springs:

[0071] According to the sprung mass m=375.26kg of the single-wheel suspension of the vehicle, and the natural frequency design value f...

Embodiment 2

[0115] Embodiment two: the sprung mass m=719.24kg of the single-wheel suspension of a certain vehicle, the natural frequency design value f of the suspension system s =1.8Hz, wherein, the length L of half of the variable-section leaf spring of the vehicle is less than 600 mm, the width b is 60 mm, and half of the installation distance is l 3 =60mm, elastic modulus E=200GPa, allowable stress [σ]=500MPa. The leaf spring with few pieces of variable cross-section is designed for this vehicle.

[0116] Using the same design method and steps as in Embodiment 1, the few parabolic variable-section leaf springs of the vehicle suspension are designed, and the specific steps are as follows:

[0117] (1) The clamping stiffness K design of the vehicle suspension with few parabolic variable-section leaf springs:

[0118] According to the sprung mass m=719.24kg of the single-wheel suspension of the vehicle, and the natural frequency design value f of the suspension system s = 1.8Hz, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com