Optimizing design method of automotive semi-active suspension magnetorheological damper piston length

A technology of magneto-rheological shock absorber and semi-active suspension, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., and can solve the problems of unspecified accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

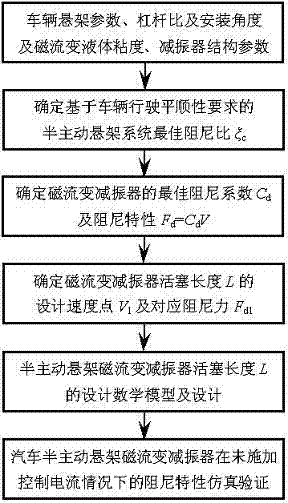

Method used

Image

Examples

Embodiment 1

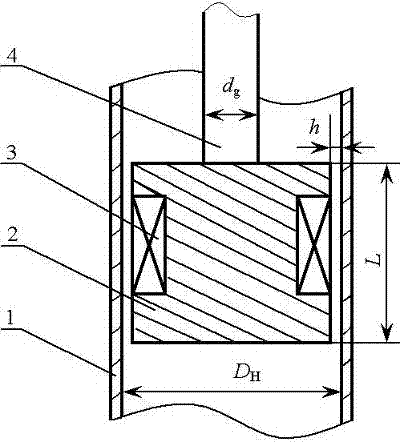

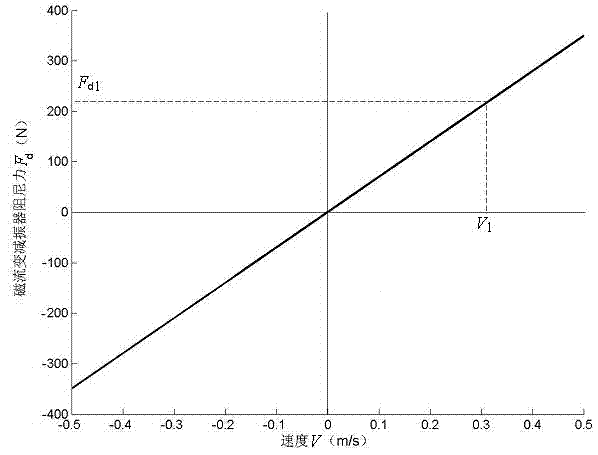

[0037] Embodiment one : Schematic diagram of the piston cylinder, piston and damping channel of a magneto-rheological shock absorber for a semi-active suspension of an automobile, as shown in figure 2 As shown, the shock absorber piston cylinder 1, piston 2, electromagnetic coil 3, and piston rod 4, wherein the electromagnetic coil 3 is embedded in the middle of the piston, and the annular gap between the piston 2 and the piston cylinder 1 h , which is the width of the damping channel of the MR damper h . The sprung mass of the car's single-wheel suspension m 2 =300kg, suspension stiffness k 2 =13057N / m, unsprung mass m 1 =40kg, tire stiffness k t =192000N / m; the inner diameter of the piston cylinder of the magneto-rheological shock absorber is D H =28mm, piston rod diameter d g =18mm, piston ring gap h =0.8mm; Suspension leverage ratio i= 0.9 and shock absorber installation angle =10°; the viscosity of the magnetorheological fluid is 0.8Pa.s when no magneti...

Embodiment 2

[0060] Embodiment two : The structural parameters of a certain automobile semi-active suspension magneto-rheological shock absorber and the initial viscosity of the magneto-rheological fluid are all the same as those in Example 1, that is, the inner diameter of the piston cylinder is D H =28mm, piston rod diameter d g =18mm, piston ring gap h =0.8mm;, the initial viscosity of the magnetorheological fluid is 0.8Pa.s; the sprung mass of the single-wheel suspension of the car m 2 =350kg, suspension stiffness k 2 = 16719N / m, unsprung mass m 1 =40kg, tire stiffness k t =192000N / m; Suspension leverage ratio i= 0.9 and shock absorber installation angle =10°; the piston length of the magneto-rheological shock absorber of the semi-active suspension of the car L design.

[0061] Adopt the design procedure of embodiment one, the piston length of the magneto-rheological shock absorber of this automobile semi-active suspension L Make a design, ie:

[0062] (1) Determine...

Embodiment 3

[0083] Embodiment three : The structural parameters of a certain automobile semi-active suspension magneto-rheological shock absorber and the initial viscosity of the magneto-rheological fluid are all the same as those in Embodiment 1, that is, the inner diameter of the piston cylinder is D H =28mm, piston rod diameter d g =18mm, piston gap h =0.7mm, the initial viscosity of the magnetorheological fluid is 0.8Pa.s; the sprung mass of the single-wheel suspension of the car m 2 =400kg, suspension stiffness k 2 = 20884N / m, unsprung mass m 1 =40kg, tire stiffness k t =192000N / m; Suspension leverage ratio i= 0.9 and shock absorber installation angle =10°; the piston length of the magneto-rheological shock absorber of the semi-active suspension of the car L design.

[0084] Adopt the design procedure of embodiment one, the piston length of the magneto-rheological shock absorber of this automobile semi-active suspension L Make a design, ie:

[0085] (1) Determine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com