Radioactive waste cement solidification line

A technology for curing radioactive waste and cement, applied in radioactive purification, nuclear engineering and other directions, can solve problems such as unfavorable development and improvement of independent technology, high cost, etc., and achieve the effect of meeting radiation protection requirements, convenient operation and high curing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

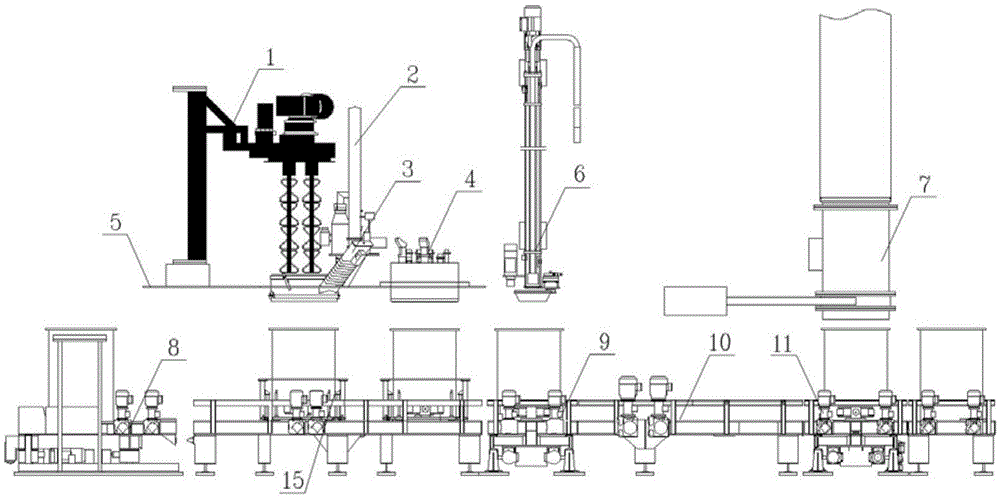

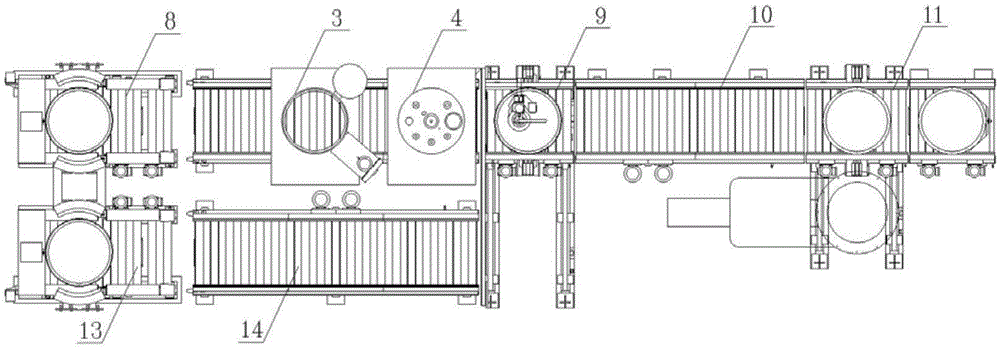

[0020] Adopt radioactive waste cement solidification line of the present invention (as attached Figure 1-2 Shown) carry out cement solidification to the radioactive concentrate of certain nuclear power plant, main steps are as follows:

[0021] (1) Make sure that the first side shifting device of the waste bin and the second side shifting device of the waste bin are located on the stacking roller table, and transfer the required number of waste bins from the cement curing workshop to the stacking roller table through the waste bin translation device, and then the waste bins are transported by the stacker The roller conveys the waste barrel to the rear of the stack roller;

[0022] (2) Transport the front waste barrel to the right below the wet material filling cover, lift it up through the jacking device, and match it with the wet material filling cover, and inject radioactivity into the waste barrel through the wet material filling cover Concentrate, after the injection is ...

Embodiment 2

[0026] Adopt radioactive waste cement solidification line of the present invention (as attached Figure 1-2 Shown) the radioactive waste resin of a nuclear power plant is cemented, and the main steps are as follows:

[0027] (1) Make sure that the first side shifting device of the waste bin and the second side shifting device of the waste bin are located on the stacking roller table, and transfer the required number of waste bins from the cement curing workshop to the stacking roller table through the waste bin translation device, and then the waste bins are transported by the stacker The roller conveys the waste barrel to the rear of the stack roller;

[0028] (2) Transport the front waste barrel directly under the wet material filling cover, lift it up through the jacking device, and match it with the wet material filling cover, and feed the radioactive waste resin in the wet material filling cover respectively The radioactive waste resin and cement slurry are filled into t...

Embodiment 3

[0031] Adopt radioactive waste cement solidification line of the present invention (as attached Figure 1-2 Shown) Carry out cement solidification to the radioactive waste filter element of certain nuclear power plant, main steps are as follows:

[0032] (1) Ensure that the first side shifting device of the waste barrel is located on the stacking roller table, hoist the waste barrel into the waste filter barrel loading device, and hoist the radioactive waste filter element into the waste barrel;

[0033] (2) Transfer the waste barrel with the radioactive waste filter element to the stacking roller table through the second side shifting device of the waste barrel, transport the waste barrel to the right below the wet material filling hood through the stacking roller table, and lift it up through the jacking device Jack up and match the wet material filling cover, fill the waste bucket with cement slurry from the cement slurry inlet of the wet material filling cover at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com