Manufacturing method of waterproof and moisture-proof temperature sensor and temperature sensor made therefrom

A technology of temperature sensor and manufacturing method, applied in thermometers, thermometers using electric/magnetic components directly sensitive to heat, semiconductor/solid-state device manufacturing, etc. problems, to achieve the effect of reliable and stable electrical properties, high shear strength and impact toughness, and high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

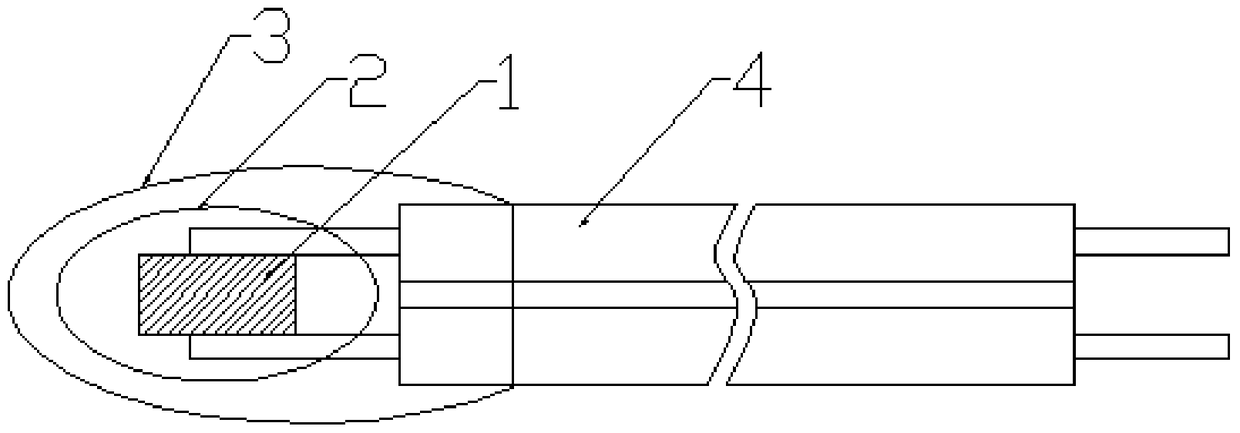

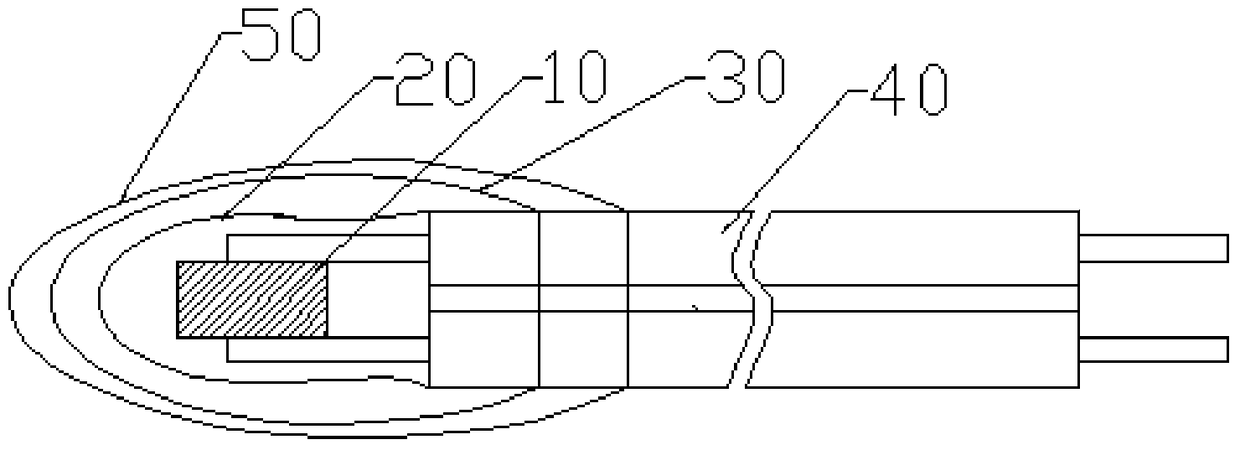

[0052] see figure 2 , which is a schematic structural diagram of the temperature sensor described in this embodiment. The waterproof and moisture-proof temperature sensor of this embodiment is made according to the following steps:

[0053] (1) Wire cutting: TPU electronic wires 40 of the same length are cut according to the set wire length;

[0054] (2) chip welding: welding a chip 10 with a temperature measuring function at one end of the TPU electronic wire 40;

[0055] (3) Epoxy resin encapsulation: Encapsulate the chip and the exposed wires with the prepared epoxy resin encapsulation material, and heat and cure to form an epoxy resin encapsulation layer 20; the epoxy resin encapsulation material is combined with The existing epoxy resin encapsulation compound is the same;

[0056] (4) TPU encapsulation: prepare a liquid TPU encapsulation material, and encapsulate a layer of liquid TPU encapsulation material outside the epoxy resin layer formed in step 3), and solidify...

Embodiment 2

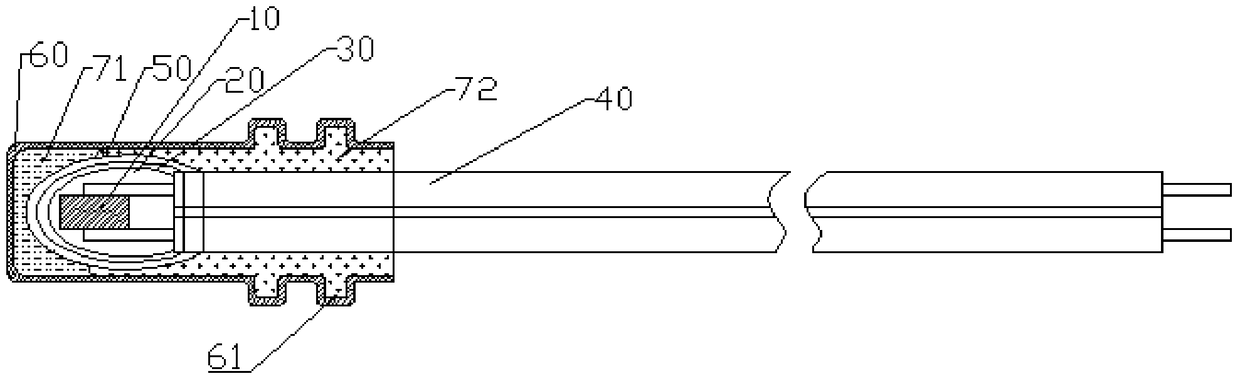

[0070] see image 3 , which is a structural schematic diagram of the waterproof and moisture-proof temperature sensor described in this embodiment. The waterproof and moisture-proof temperature sensor of this embodiment is made according to the following steps:

[0071] (1) Wire cutting: TPU electronic wires 40 of the same length are cut according to the set wire length;

[0072] (2) chip welding: welding a chip 10 with a temperature measuring function at one end of the TPU electronic wire 40;

[0073] (3) Epoxy resin encapsulation: Encapsulate the chip and the exposed wires with the prepared epoxy resin encapsulation material, and heat and cure to form an epoxy resin encapsulation layer 20; the epoxy resin encapsulation material is combined with The existing epoxy resin encapsulation compound is the same;

[0074] (4) TPU encapsulation: prepare a liquid TPU encapsulation material, and encapsulate a layer of liquid TPU encapsulation material outside the epoxy resin layer fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com