TE mode dielectric resonator device

A dielectric resonator and dielectric resonance technology, which is applied in the field of communication, can solve the problems of large force on the bottom of the lower support, deterioration of near-end suppression, and influence on the electrical performance of TE mode dielectric resonators, so as to achieve uniform force and improve passive Intermodulation, the effect of solving poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

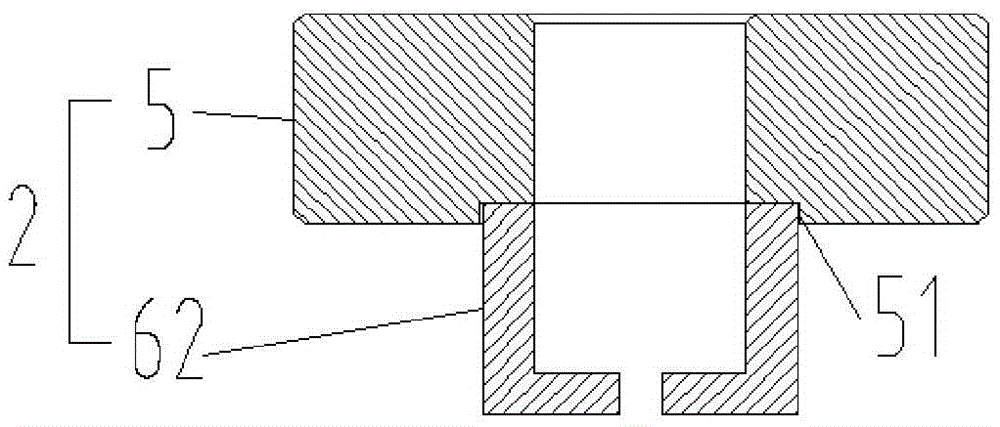

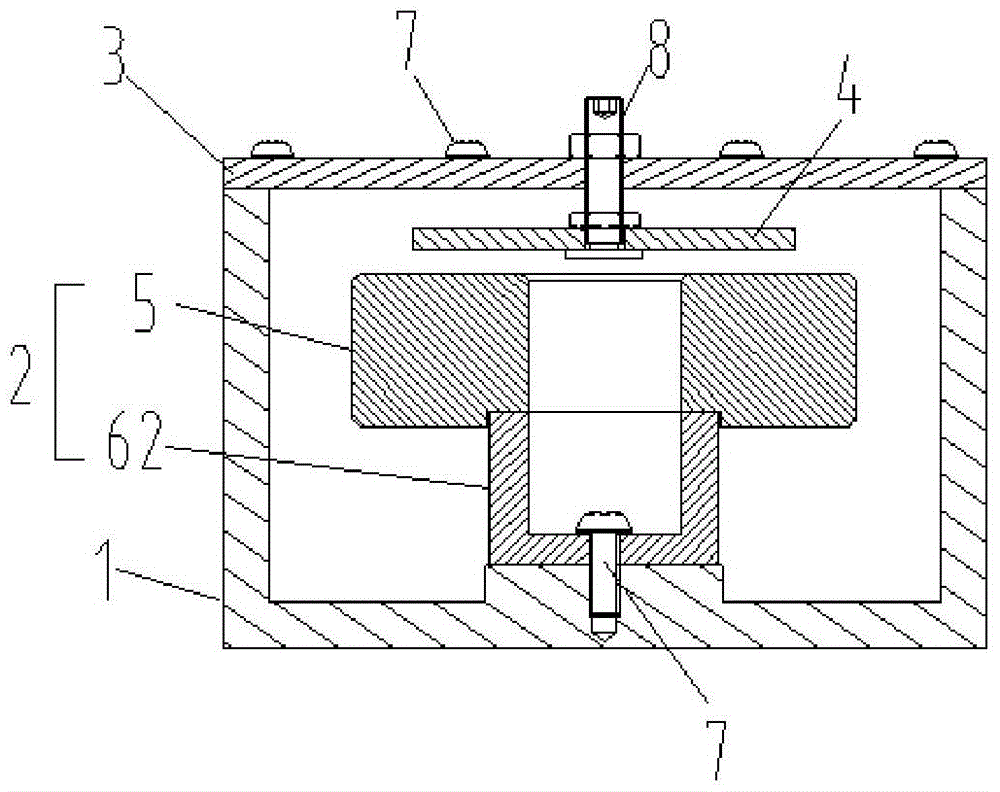

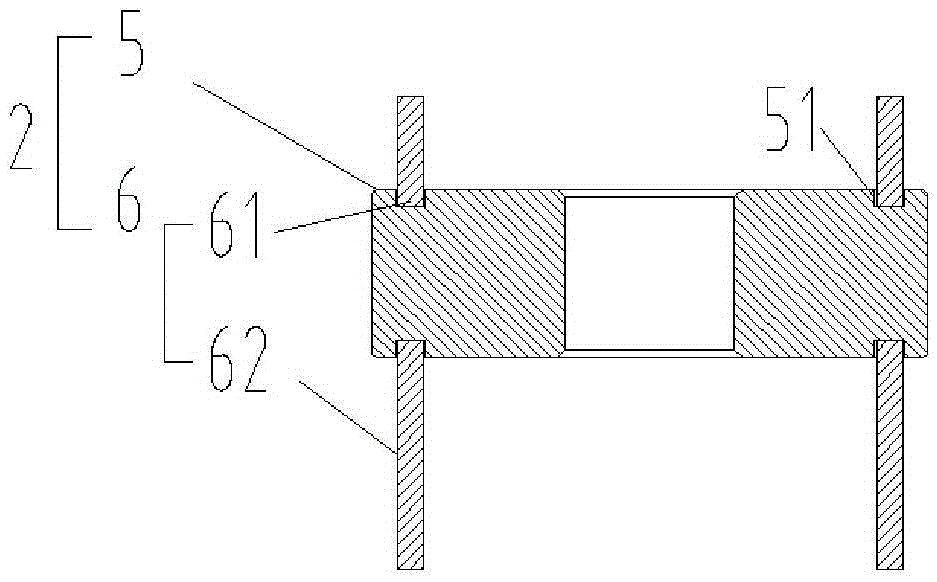

[0058] Such as image 3 , Figure 4 and Figure 5 As shown, the structural diagram of the TE mode dielectric resonator device provided by Embodiment 1 of the present invention includes a cavity 1, a TE01 mode dielectric resonator 2 installed in the cavity 1, and a cover plate 3 mounted on the top of the cavity 1 , a TE01-mode dielectric disk 4 is installed at the bottom of the cover plate 3, and the TE01-mode dielectric resonator 2 is composed of a TE01-mode dielectric resonator rod 5 and a support seat 6 installed thereon. The surface and the bottom surface of the resonant rod 5 are respectively provided with draw-in slots 51, and the upper support base 61 and the lower support base 62 are clamped respectively on the draw-in slots 51, and the lower support base 62 is clamped in the limit groove 11, and the top of the upper support base 61 and the The top of the cavity 1 is arranged horizontally and collinearly. The cover plate 3 includes an inner cover plate 31 and an outer...

Embodiment 2

[0076] This embodiment is a further improvement on the TE mode dielectric resonator device provided in the first embodiment. On the basis of the structure of the first embodiment, the cover plate 3 is connected to the cavity 1 as a whole through six ring-shaped connectors 7 .

Embodiment 3

[0078] This embodiment is a further improvement on the TE mode dielectric resonator device provided in the first embodiment. On the basis of the structure of the first embodiment, the cover plate 3 is integrally connected with the cavity 1 through seven ring-shaped connectors 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com