Polyurethane foam and associated method and article

A technology of polyurethane foam and blowing agent, applied in the field of polyurethane foam and related and products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] Embodiment 1: A polyurethane foam comprising the product of a reaction mixture comprising: a polyol comprising a poly(ethylene glycol) having a number average molecular weight of 600 to 2000 atomic mass units and an average of 1.5 to 3 hydroxyl groups per molecule phenyl ether); an aromatic isocyanate compound having an average of at least 2 isocyanate groups per molecule; and a blowing agent; wherein the reaction mixture is characterized by an isocyanate index of 65 to 95; and wherein the polyurethane foam has an isocyanate index according to ASTM D3574- 08 Test A Density of 0.01 to 0.16 g / cm3 measured at 23°C.

Embodiment approach 2

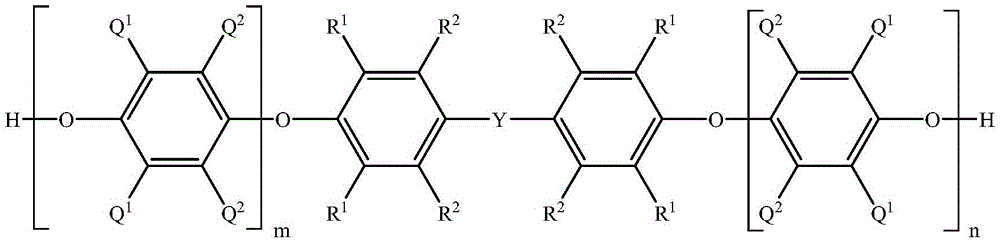

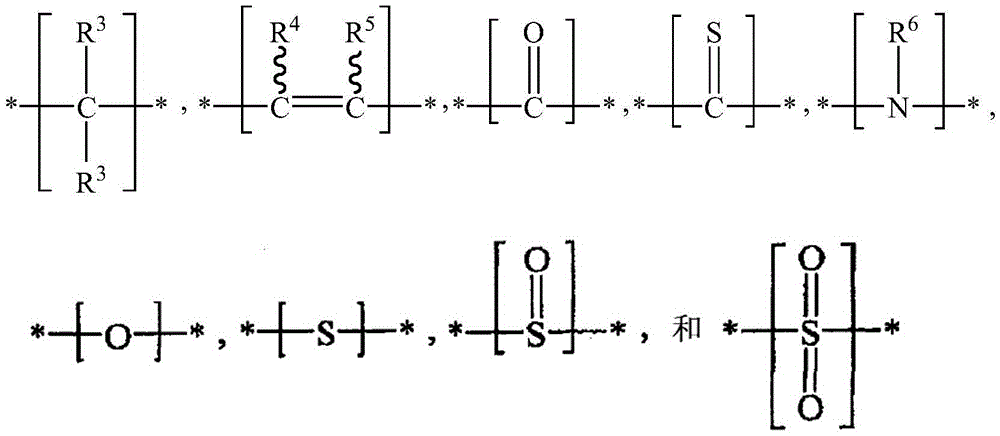

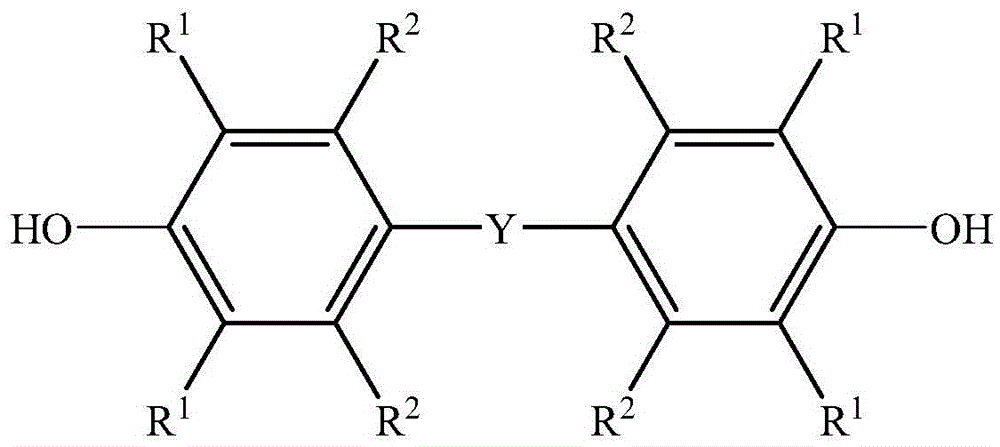

[0060] Embodiment 2: The polyurethane foam of Embodiment 1, wherein the poly(phenylene ether) is a copolymer comprising monomers of monohydric and dihydric phenols.

Embodiment approach 3

[0061] Embodiment 3: The polyurethane foam of Embodiment 2, wherein the monohydric phenol comprises 2,6-dimethylphenol and the dihydric phenol comprises 2,2-bis(3,5-dimethyl-4-hydroxybenzene base) propane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com