Steamed bun making machine

A steamed bread machine and component technology, which is applied in the fields of dough sheeter/roller/rolling pin, food science, baking, etc., can solve the problems of low efficiency, monotonous color of steamed buns, unable to meet the requirements of various two-color steamed buns, etc. The effect of fast speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

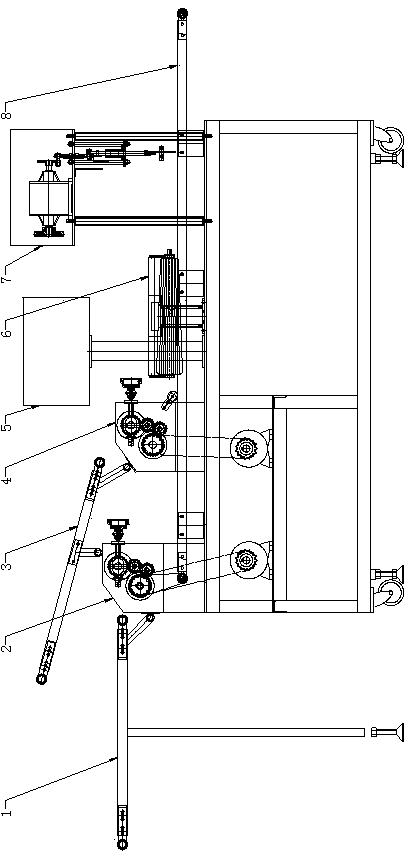

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it consists of the forward surface conveying assembly 1, the front pressing roller assembly 2, the backward advancing surface conveying assembly 3, the rear pressing roller assembly 4, the control box 5, the rolling roller assembly 6, the cutter The box assembly 7 and the rear conveyor belt assembly 8 are composed. The front surface roller assembly 2 is connected to the front surface conveying assembly 1, and the front surface roller assembly 2 is provided with a rear surface conveying assembly 3. The front surface roller assembly 2 The rear conveyor belt assembly 8 is connected to the back, and the rear conveyor belt assembly 8 is provided with a rear pressing roller assembly 4, a control box 5, a rolling roller assembly 6, and a cutter box assembly 7.

[0009] When this specific embodiment is working normally, a kind of dough is placed on the conveyor belt of the forward surface conv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap