Complete casting, demolding, taking and conveying device

A complete set of equipment and demoulding technology, which is applied in casting equipment, metal processing equipment, ingot casting workshops, etc., can solve the problems affecting the personal safety of operators, high heat in casting workshops, and hindering the progress of molten iron, so as to reduce labor intensity, The effect of improving the working environment and avoiding close contact with molding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

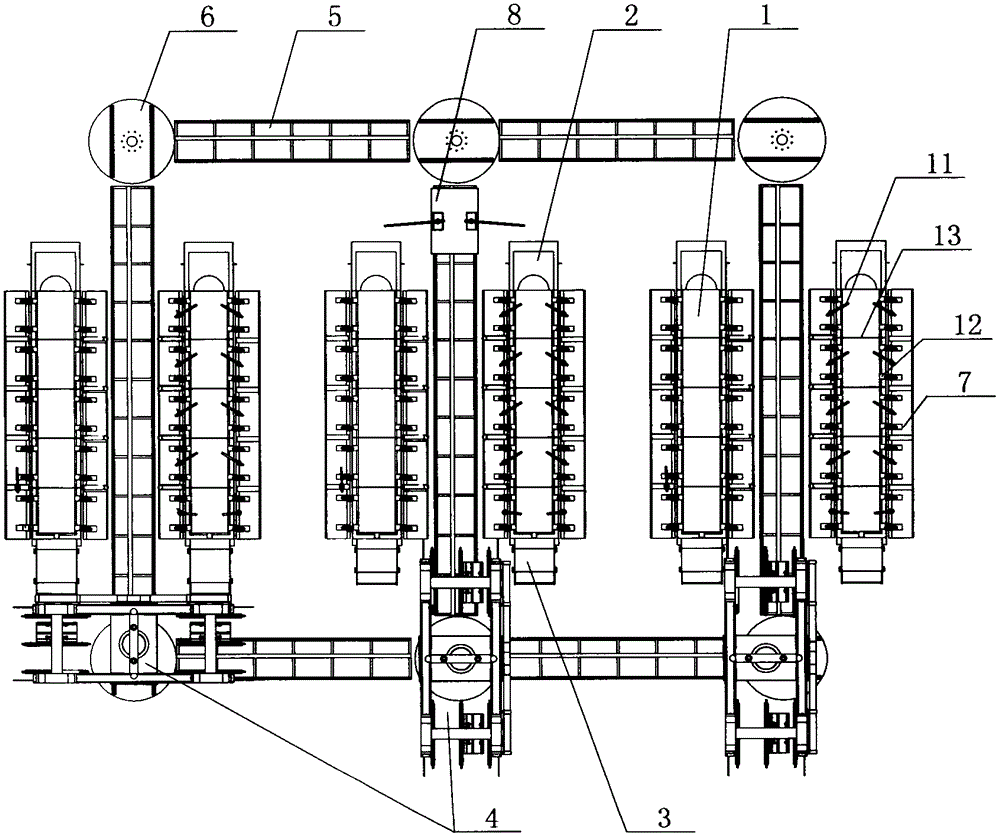

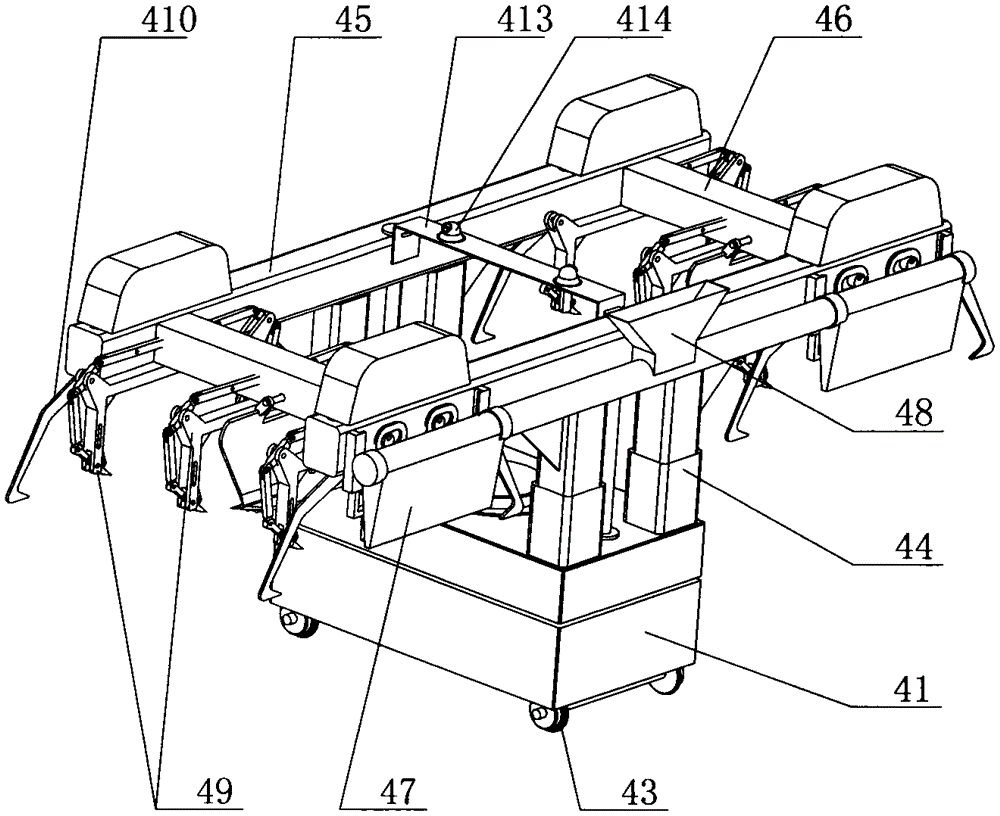

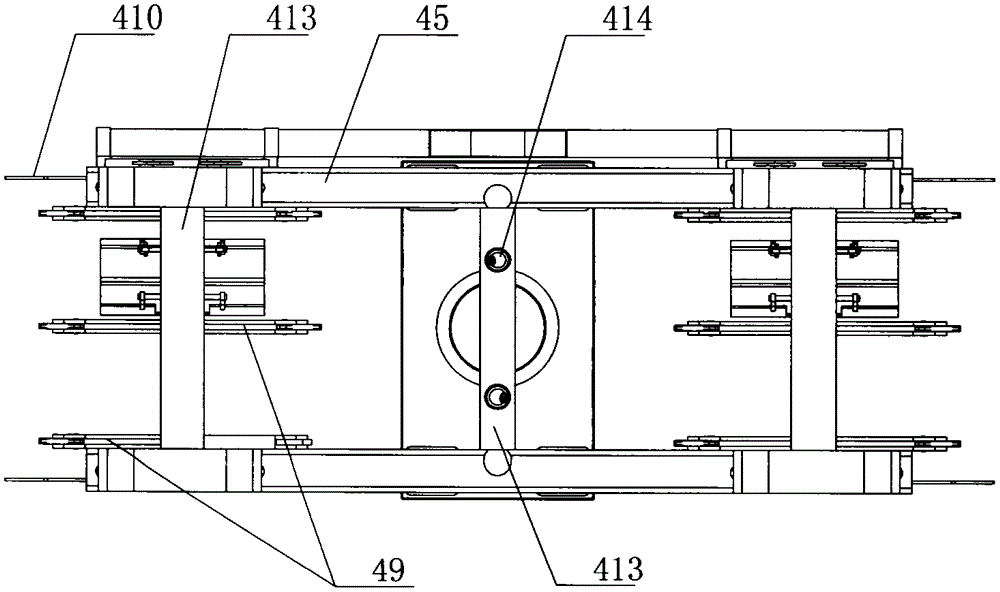

[0040] Such as Figure 1 to Figure 6 As shown, this specific embodiment adopts the following technical solutions: it includes an ingot mold 1, a casting port 2, a storage car 3, a fetching car 4, a track 5, a track steering device 6, a prying module 7, and a drainage car 8; Both sides of described ingot mold 1 are provided with prying module 7 symmetrically; The bottom of described prying module 7 is fixed on the ground; Described ingot mold 1 is provided with track 5 around; 5 is a circular track; the corners of the track 5 are provided with a track steering device 6; one end of the ingot mold 1 is provided with a casting port 2; the other end of the ingot mold 1 is provided with a storage car 3 The described drainage vehicle 8 is movably arranged on the track 5; the described drainage vehicle 8 is provided with a swing manipulator 81; the described swing manipulator 81 is provided with a drainage stick 82; On track 5; Described fetching car 4 comprises base 41, drive unit 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com