A small-scale demolition crowbar for industrial building engineering construction

A technology for engineering construction and industrial construction, applied in construction, building maintenance, building construction, etc., can solve problems such as single prying method, screw thread damage, combined prying, etc., to reduce potential safety hazards, enhance use strength, prevent The effect of turning and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

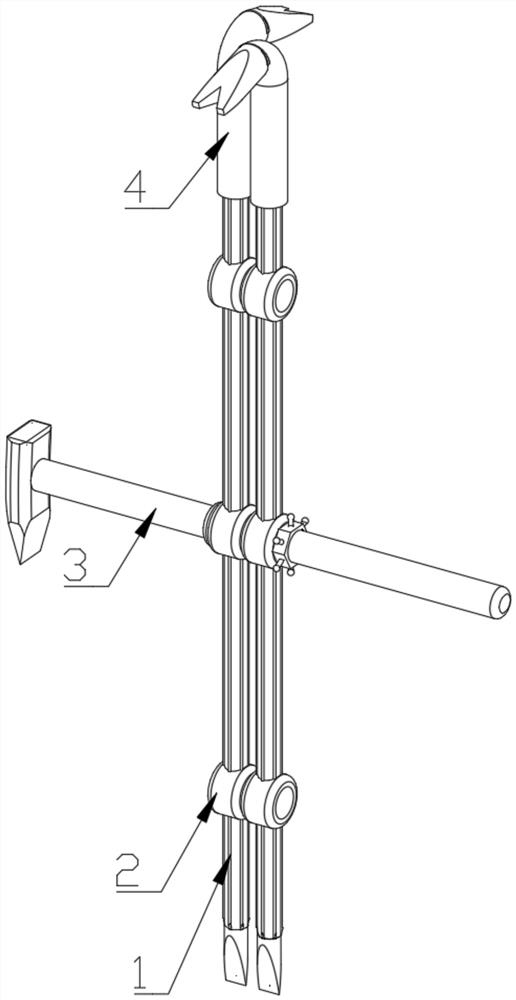

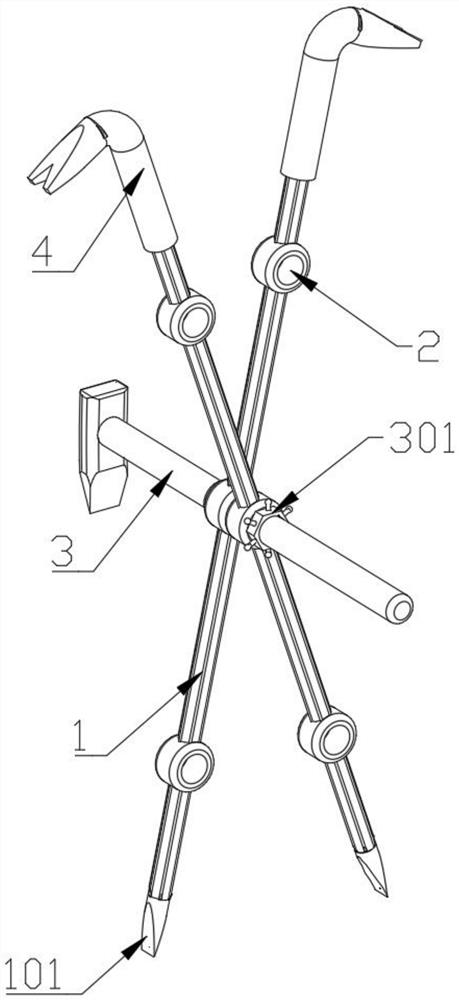

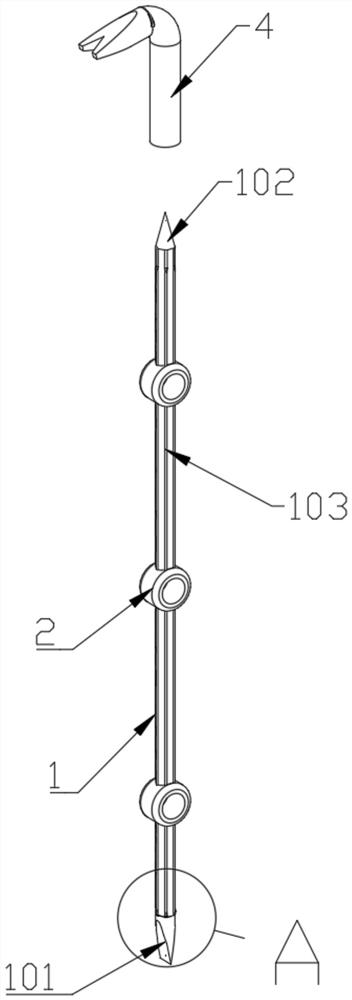

[0040] as attached figure 1 to attach Figure 9 Shown:

[0041] The present invention provides a small-scale demolition crowbar for industrial construction engineering construction, including: a crowbar main body 1, a crowbar flat head 101, a crowbar conical head 102, a reinforced anti-slip edge 103, a fixed collar 2, and a fixed pick Hammer 3, fixed nut 301, limit ring 302, fixed thread 303, nail head 4 and elongated stick body 5; three fixed collars 2 are equidistantly arranged on the stick body on the described crowbar main body 1, and the fixed sleeve The ring 2 and the crowbar main body 1 are integrally cast; the crowbar main body 1 is composed of a crowbar flat head 101, a crowbar conical head 102 and a reinforced anti-slip edge 103, and the crowbar flat head 101 and the crowbar conical head 102 They are respectively arranged at both ends of the crowbar main body 1; the fixed collar 2 is inserted into and installed with a fixed pick hammer 3;

[0042] Wherein, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com