Sintering mold

A technology for molds and mold bodies, applied in the field of sintering molds, can solve problems such as low productivity and inability to handle multiple batches of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0025] The sintering mold provided by the invention is suitable for sintering systems such as pulse discharge plasma sintering, direct current sintering or hot pressing sintering. Below in conjunction with specific embodiment the sintering mold of the present invention is introduced in detail:

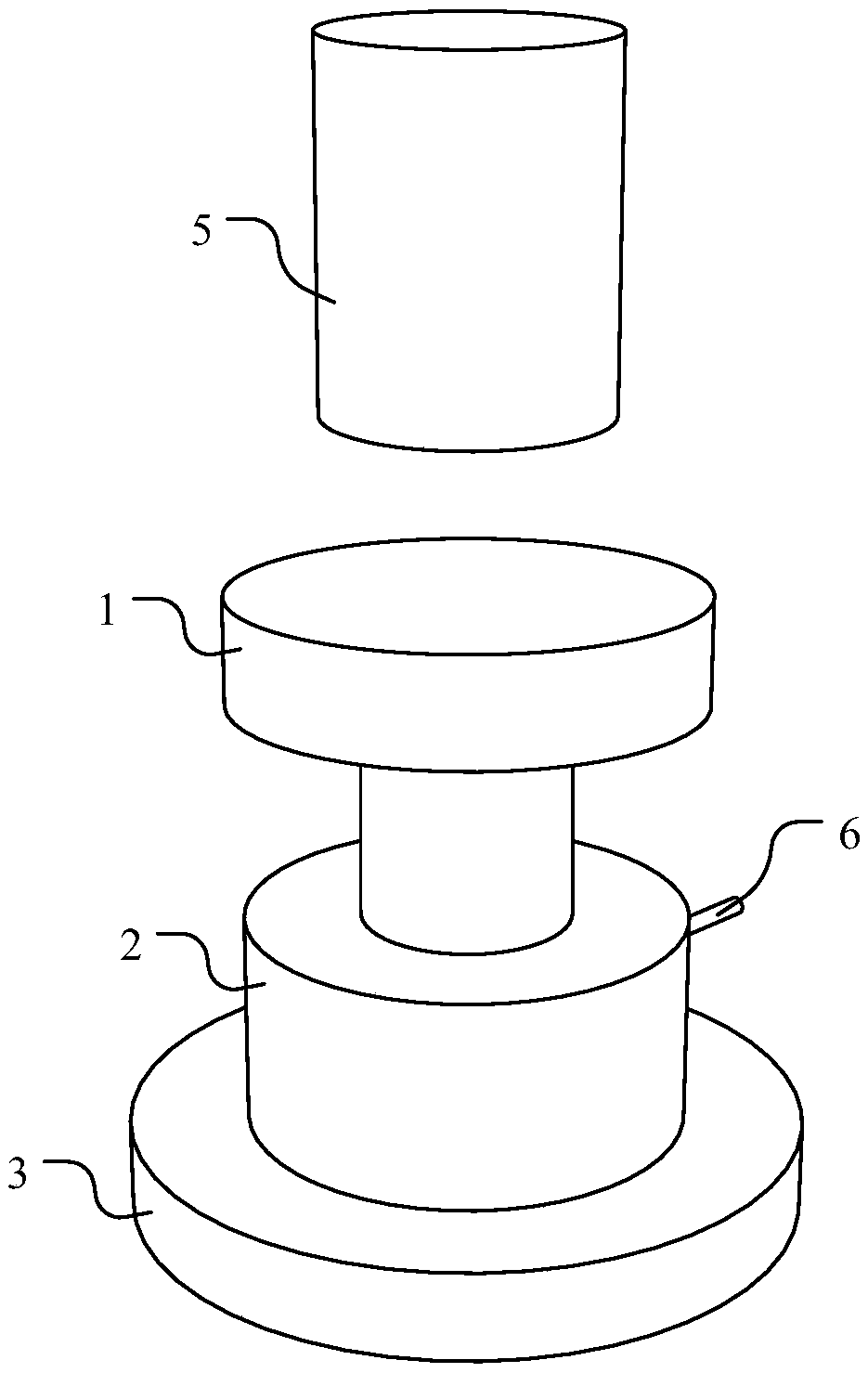

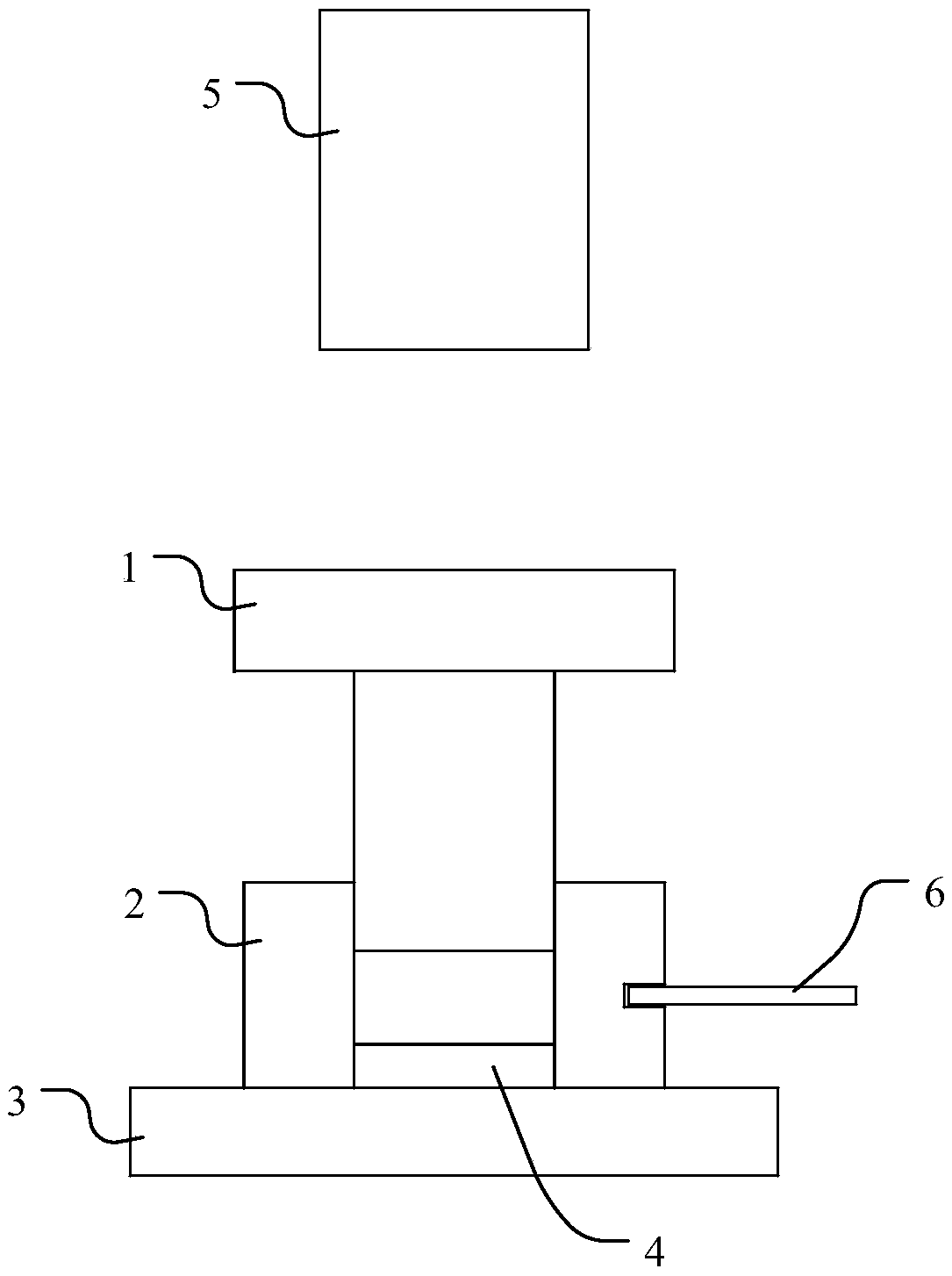

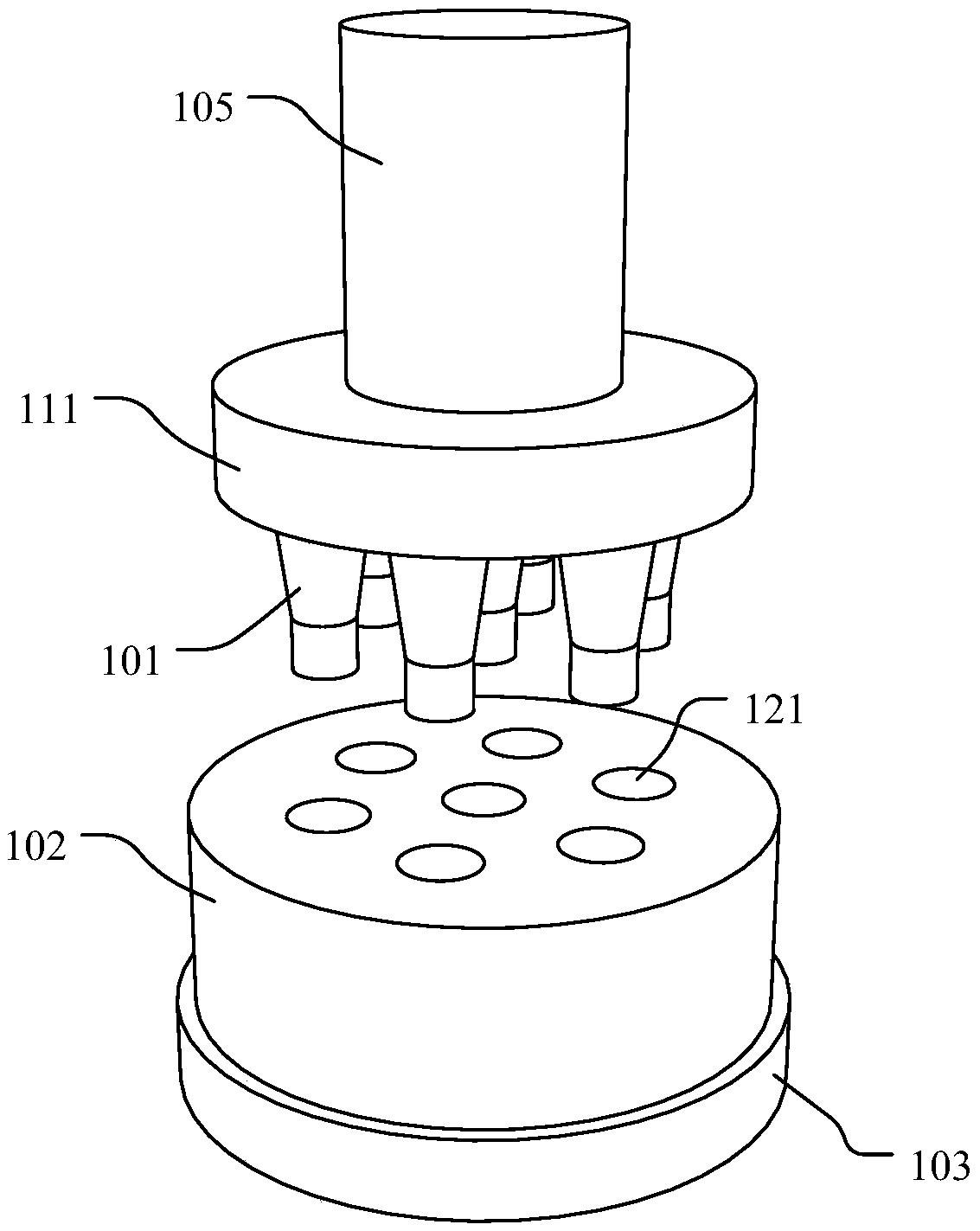

[0026] Such as image 3 , 4 As shown, the sintering mold provided by the present invention includes an indenter 101 , a mold body 102 , a pressure-bearing platform 103 and a gasket 104 . The mold main body 102 is a cylindrical structure with a certain thickness, and a plurality of cavities 121 are arranged along its axial direction, and the cavities 121 are through holes com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com