Machining method of internal herringbone gear

A processing method, herringbone technology, applied to components with teeth, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problem of affecting product quality and equipment operation stability and reliability, common normal line size is not the same, The problems such as the increase of the medium error of the internal teeth can achieve the effect of stable quality, good consistency, easy production, and improved centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

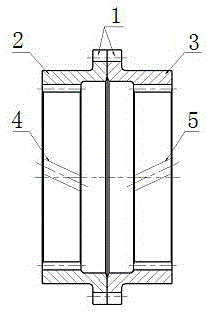

[0030] The processing method of inner herringbone gear of the present invention is as follows:

[0031] A. Fabrication of the centering fixture of the inner herringbone gear, the centering fixture includes a positioning sleeve 9 and a pressure plate 6.

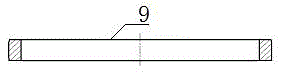

[0032] A1, the production of the positioning sleeve 9, the outer peripheral surface of the positioning sleeve 9 is in clearance fit with the inner peripheral surface of the ring gear, and the wall thickness of the sleeve is 15 mm.

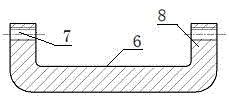

[0033] A2, the production of the pressing plate 6, the pressing plate 6 is a concave structure, with pressing heads 8 arranged at both ends, and pressing screw holes 7 are arranged on the pressing heads 8.

[0034] B. Gear blank processing;

[0035] C. Insert helical teeth;

[0036] D. Centering of inner helical teeth;

[0037] D1. The left ring gear 2 and the right ring gear 3 are combined to form a ring gear. Install the pressure plate 6 on the upper and lower ends of the ring gear, tighten th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com