Finishing method and device for two-half-tile thin-wall bushing

A thin-walled and bushing technology, which is applied in the processing of thin-walled parts, can solve problems such as excessive deformation of parts and non-concentricity of inner and outer circles, and achieve the effects of small force, time-saving alignment and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

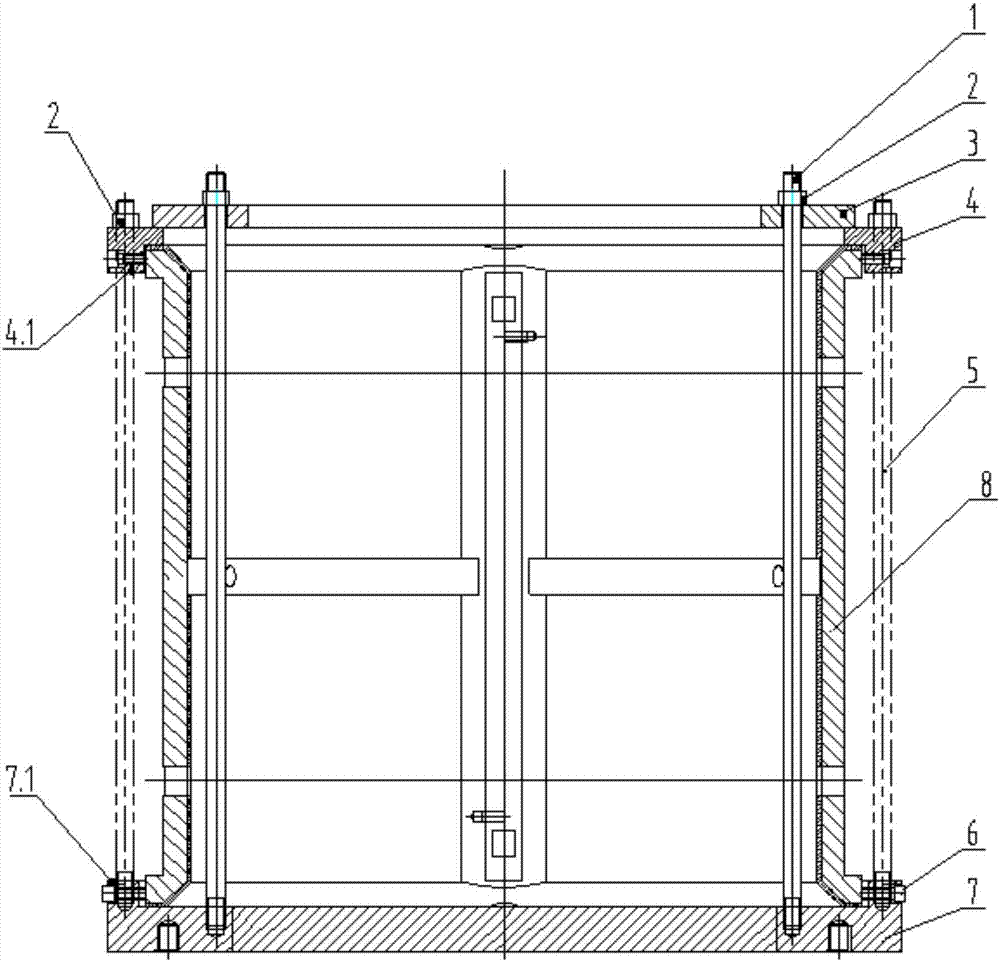

[0022] Typical embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the descriptions and diagrams therein are for illustrative purposes, not for limiting the present invention.

[0023] Such as image 3 As shown, a finishing method of two and a half tile thin-walled bushings, the steps are as follows:

[0024] ① Install the round mould 7 on the chuck of the vertical grinder and align it with the chuck;

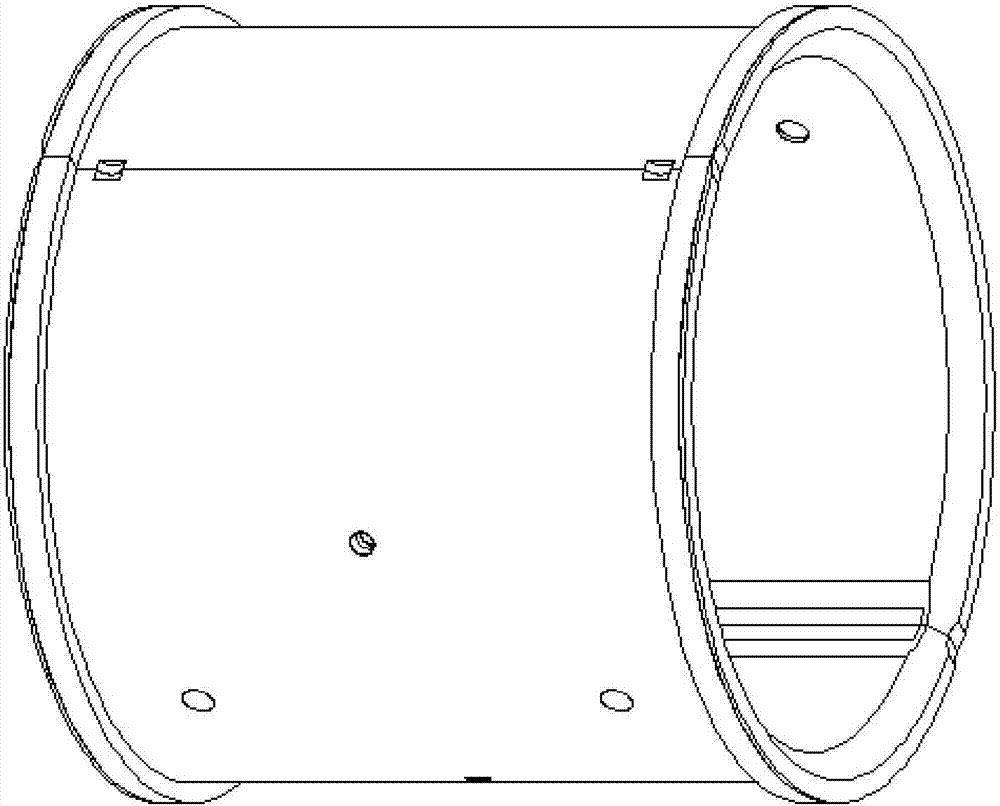

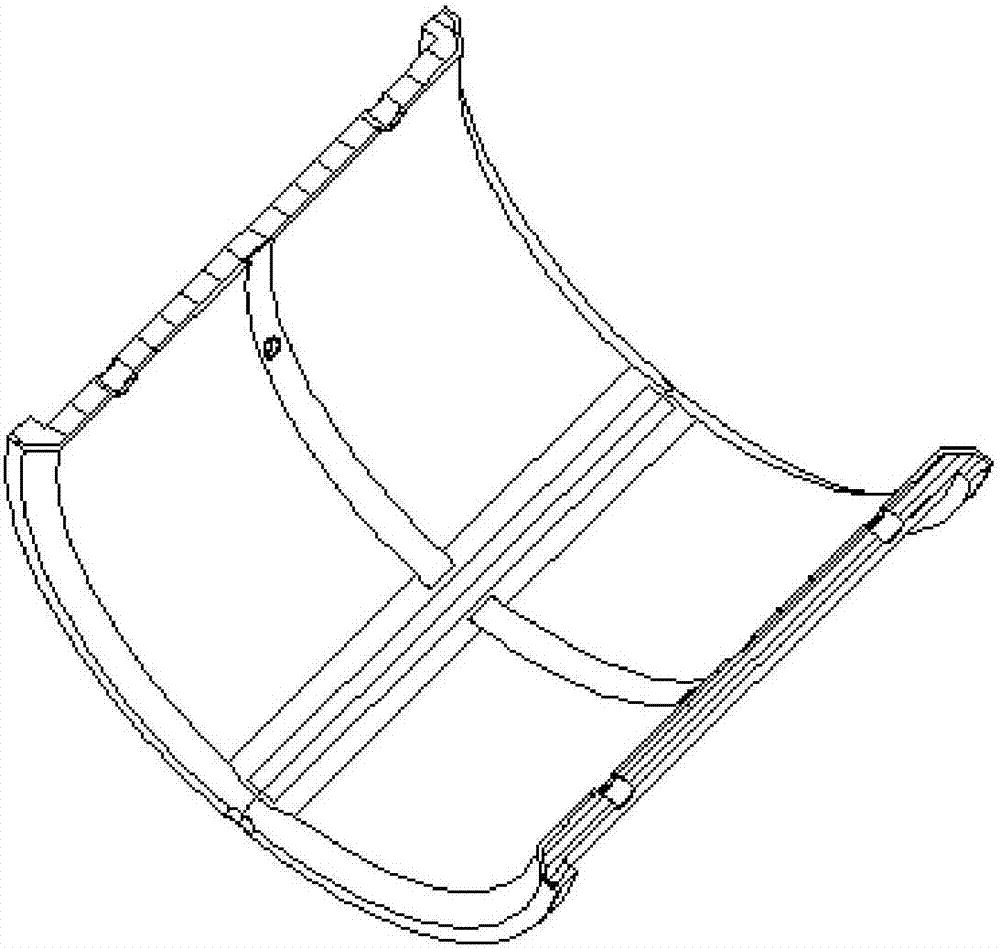

[0025] ② Put the two-half-tile thin-walled bushing 8 upright on the round mold 7, and place the No. Ⅱ blank cover 4 and the No. Ⅰ blank cover 3 on the upper end of the two-half tile thin-walled bushing 8 in sequence;

[0026] ③ Align the outer circle of the two-half-tile thin-walled bushing 8 through the aligning screw 6 set in the counterbore of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com