A kind of preparation method of nanocrystalline aluminum alloy plate material

A technology of aluminum alloy plate and aluminum alloy plate, which is applied in the field of material processing, can solve problems such as difficulty in producing ultra-fine grain structure, coarse grain structure strength, low recrystallization driving force, etc., and achieve remarkable grain refinement effect, Short production cycle, improved strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

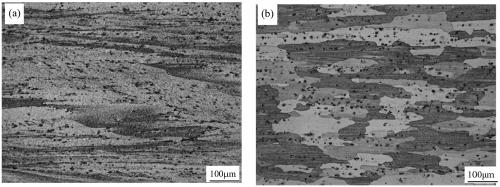

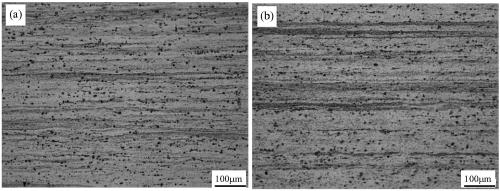

[0045] An ultra-fine-grained aluminum alloy plate, its chemical composition and mass percentage are: Si: 0.45%, Mg: 1.0%, Cu: 0.15%, Mn: 0.15%, Cr: 0.24%, Zn: 0.25%, Ti: 0.15%, the balance is Al and unavoidable impurities. The thickness of the ultrafine-grained aluminum alloy plate is 1 mm.

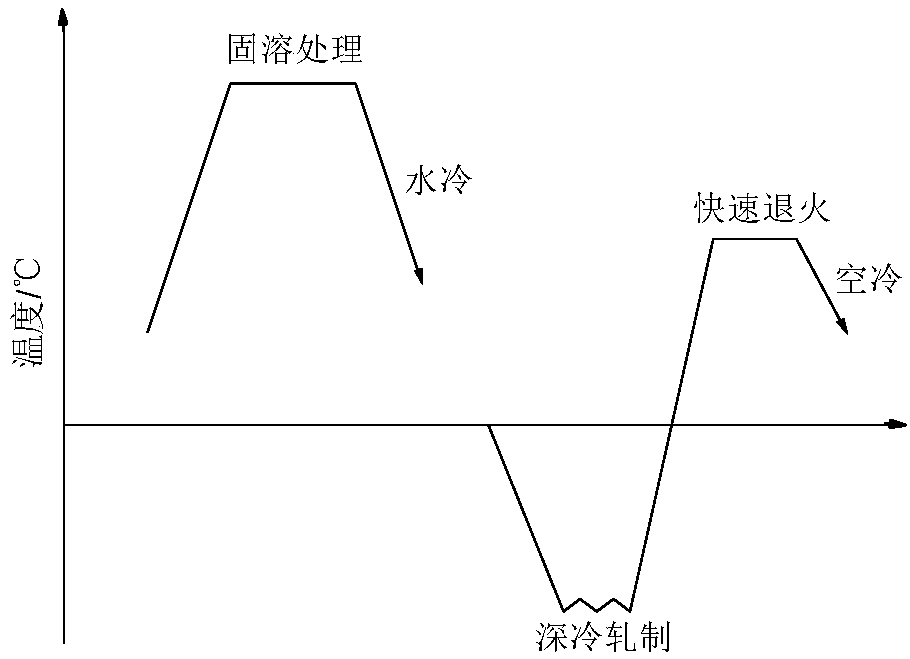

[0046] The preparation method of the above-mentioned ultrafine-grained aluminum alloy plate specifically includes the following steps:

[0047] Step 1, hot rolling:

[0048] (1) Heat an aluminum alloy billet with a thickness of 25mm to 450°C in a resistance furnace and keep it warm for 2h;

[0049] (2) Hot rolling the aluminum alloy billet after heat preservation for 7 passes, the starting rolling temperature is 450°C, the final rolling temperature is 280°C, the total cumulative reduction rate is 80%, and then air-cooled to room temperature to obtain a thickness of 5mm hot rolled plate;

[0050] Step 2, cryogenic rolling:

[0051] (1) Solution treatment: heat the hot-rolled plate to 53...

Embodiment 2

[0058] An ultra-fine-grained aluminum alloy plate, its chemical composition and mass percentage are: Si: 0.45%, Mg: 1.0%, Cu: 0.15%, Mn: 0.15%, Cr: 0.24%, Zn: 0.25%, Ti: 0.15%, the balance is Al and unavoidable impurities. The thickness of the ultra-fine grain aluminum alloy plate is 1.75mm.

[0059] The preparation method of the above-mentioned ultrafine-grained aluminum alloy plate specifically includes the following steps:

[0060] Step 1, hot rolling:

[0061] (1) Heat an aluminum alloy billet with a thickness of 25mm to 450°C in a resistance furnace and keep it warm for 2h;

[0062] (2) Hot rolling the aluminum alloy billet after heat preservation for 7 passes, the starting rolling temperature is 450°C, the final rolling temperature is 280°C, the total cumulative reduction rate is 80%, and then air-cooled to room temperature to obtain a thickness of 5mm hot rolled plate;

[0063] Step 2, cryogenic rolling:

[0064] (1) Solution treatment: heat the hot-rolled plate to...

Embodiment 3

[0071] An ultra-fine-grained aluminum alloy plate, its chemical composition and mass percentage are: Si: 0.45%, Mg: 1.0%, Cu: 0.15%, Mn: 0.15%, Cr: 0.24%, Zn: 0.25%, Ti: 0.15%, the balance is Al and unavoidable impurities. The thickness of the ultra-fine grain aluminum alloy plate is 2mm.

[0072] The preparation method of the above-mentioned ultrafine-grained aluminum alloy plate specifically includes the following steps:

[0073] Step 1, hot rolling:

[0074] (1) Heat an aluminum alloy billet with a thickness of 25mm to 450°C in a resistance furnace and keep it warm for 2h;

[0075] (2) The aluminum alloy billet after heat preservation is subjected to 6 passes of hot rolling, the rolling temperature is 450°C, the final rolling temperature is 300°C, the total cumulative reduction rate is 75%, and then air-cooled to room temperature to obtain a thickness of 5mm hot rolled plate;

[0076] Step 2, cryogenic rolling:

[0077] (1) Solution treatment: heat the hot-rolled plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com