Compact faeces collecting system

A compact and stool-collecting technology, which is applied in the field of bathroom toilets, can solve the problems of low noise, waste of water, and insufficient compact and simplified structure, and achieve the effect of simple process, efficient collection, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing, but should not be limited to following embodiment:

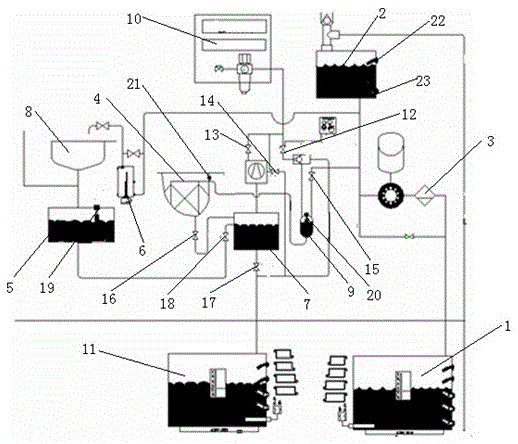

[0057] figure 1 It is the schematic diagram of the overall structure of the compact stool collection system of the present invention, according to figure 1 Describe the working principle of this system. The compact stool collection system includes clean water tank 1, overhead water tank 2, upper water pump 3, toilet 4, waste water collection tank 5, warm water tank 6, transfer box 7, wash basin 8, pressurized water tank 9, control module 10, sewage Object box 11 and water supply tray. The overhead water tank 2 is installed on the top of the toilet, the clean water tank 1 and the dirt tank are installed below the bottom plate of the toilet, the upper water pump 3, the toilet 4, the waste water collection tank 5, the warm water tank 6, the transfer box 7, the wash basin 8, the booster Pressurized water tank 9, the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com