Cardboard labeling equipment

A cardboard and equipment technology, applied in the field of cardboard labeling equipment, can solve the problems of complex labeling process, high labor cost, inaccurate labeling, etc., and achieve labor cost saving, simple labeling process and accurate labeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

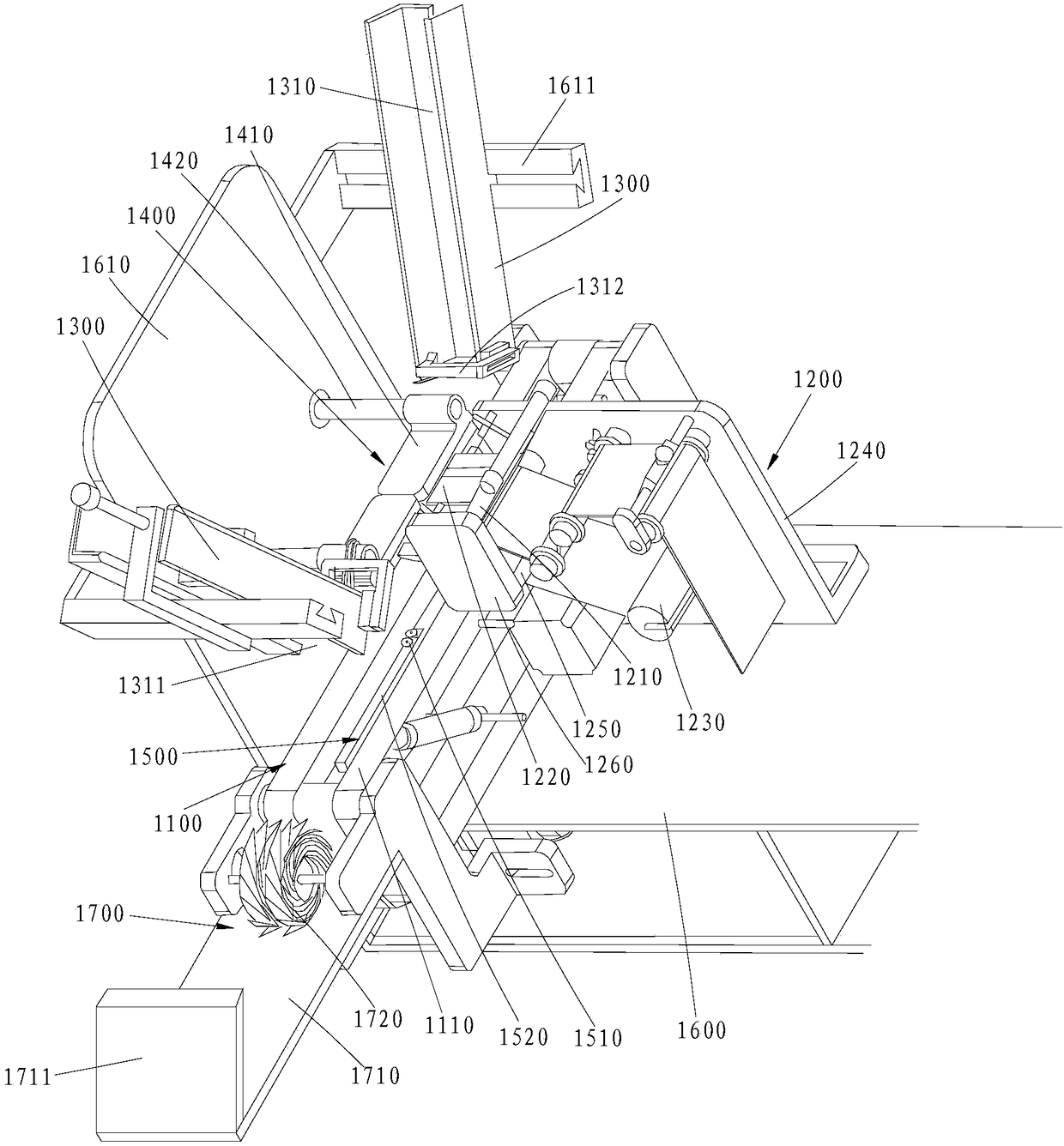

[0024] Such as figure 1 As shown, a paper jam labeling equipment includes a paper jam conveying mechanism 1100 , a label feeding mechanism 1200 , a paper jam silo 1300 , a label taking and labeling mechanism 1400 , a paper jam transfer mechanism 1500 and a chassis 1600 .

[0025] The jam conveying mechanism 1100 is used to convey the labeled jam, which is fixed on the bottom frame 1600 and has two conveying belts 1110 arranged at intervals.

[0026] The label feeding mechanism 1200 is used to transport the label paper and peel off the label on the label paper, which includes two driving rollers 1210 , a label stripping shovel 1220 and a backing paper winding roller 1230 .

[0027] The two driving rollers 1210 are arranged at intervals up and down, a piece of label paper can pass between them and can be driven forward by clamping the label paper. The stripping shovel 1220 is located at the front side of the driving direction of the two driving rollers 1210, The label labeling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com