The preparation technology of rilpivirine intermediate

A technology for rilpivirine and a preparation process, which is applied in the field of preparation technology for synthesizing rilpivirine intermediates, can solve the problems of high catalyst cost, harsh process conditions, troublesome post-processing and the like, and achieves good product quality, simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

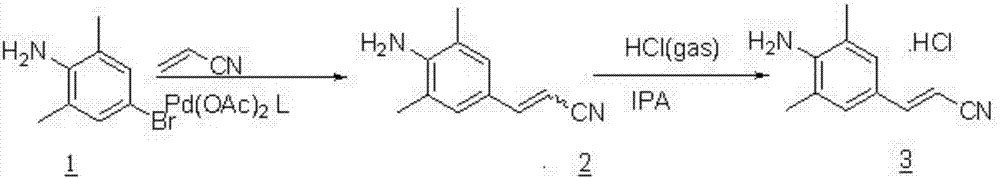

[0015] (compound 2 Synthesis)

[0016] A 20L four-neck flask equipped with a thermometer, mechanical stirring, a constant pressure dropping funnel, and an exhaust gas absorption device was replaced with nitrogen three times, and THF (10L), palladium acetate (5.6g, 0.5%mol) and phosphine ligand L (28g, 1% mol), stirred at 20-30°C for 1 hour. Sodium acetate (1.02Kg, 7.5mol), 4-bromo-2,6-dimethylaniline (1.0Kg, 5mol) and acrylonitrile (405g, 7.5mol) were added sequentially. Continue to stir and react at 20-30°C for 4 hours, then add water (5.0 L), let stand to separate the layers, separate the organic phase, and extract the aqueous phase with tertiary methyl ether (5 L) once. The organic phases were combined and concentrated under reduced pressure to obtain 870 g of crude 3-(4-amino-3,5-dimethylphenyl)acrylonitrile (trans:cis=4.6:1), and the crude yield was 102%.

[0017] (compound 3 Synthesis)

[0018] In the 20L four-neck flask equipped with thermometer, mechanical stirrin...

Embodiment 2

[0022] (compound 2 Synthesis)

[0023] A 20L four-necked flask equipped with a thermometer, mechanical stirring, a constant pressure dropping funnel, and an exhaust gas absorption device was replaced with nitrogen three times, and THF (10L), palladium acetate (1.2g, 0.1%mol) and phosphine ligand L (6g, 0.2% mol), stirred at 20-30°C for 1 hour. Sodium acetate (1.02Kg, 7.5mol), 4-bromo-2,6-dimethylaniline (1.0Kg, 5mol) and acrylonitrile (405g, 7.5mol) were added sequentially. Continue to stir and react at 20-30°C for 4 hours, then add water (5.0 L), let stand to separate the layers, separate the organic phase, and extract the aqueous phase with tertiary methyl ether (5 L) once. The organic phases were combined and concentrated under reduced pressure to obtain 870 g of crude 3-(4-amino-3,5-dimethylphenyl)acrylonitrile (trans:cis=4.7:1), and the crude yield was 102%.

[0024] (compound 3 Synthesis)

[0025] In the 20L four-neck flask equipped with thermometer, mechanical stir...

Embodiment 3

[0027] (compound 2 Synthesis)

[0028] A 20L four-neck flask equipped with a thermometer, mechanical stirring, a constant pressure dropping funnel, and an exhaust gas absorption device was replaced with nitrogen three times, and THF (10L), palladium acetate (5.6g, 0.5%mol) and phosphine ligand L (28g, 1% mol), stirred at 20-30°C for 1 hour. Sodium acetate (1.02Kg, 7.5mol), 4-bromo-2,6-dimethylaniline (1.0Kg, 5mol) and acrylonitrile (405g, 7.5mol) were added sequentially. Continue to stir and react at 20-30°C for 4 hours, then add water (5.0 L), let stand to separate the layers, separate the organic phase, and extract the aqueous phase with tertiary methyl ether (5 L) once. The organic phases were combined and concentrated under reduced pressure to obtain 870 g of crude 3-(4-amino-3,5-dimethylphenyl)acrylonitrile (trans:cis=4.6:1), and the crude yield was 102%.

[0029] (compound 3 Synthesis)

[0030] In the 20L four-neck flask equipped with thermometer, mechanical stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com