A kind of preparation method of pyrrole derivative

A technology of pyrrole derivatives and pyrrole, applied in the direction of organic chemistry, etc., can solve the problems of long reaction time, difficult industrial production, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

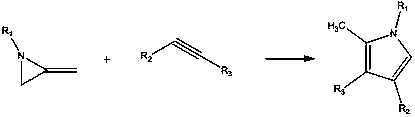

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

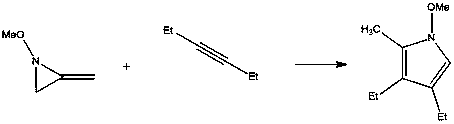

Embodiment 1

[0021]

[0022] Add 5mol% (relative to the alkyne) silver azotetrazole catalyst C in sequence in a 20ml flask 3 h 8 AgN 7 , then add 20mmol methylene aziridine and 10mmol alkyne, add 10ml toluene, and finally react at room temperature 25°C for 2h. After the reaction was completed, the reaction was filtered, the solvent was concentrated and evaporated by a rotary evaporator, the solid was subjected to silica gel column chromatography, and the column was washed with an eluent of petroleum ether:ethyl acetate=20:1 to obtain the target pyrrole compound with a yield of 90%. Purity≥99%.

Embodiment 2

[0024]

[0025] Add 4mol% (relative to the alkyne) silver azotetrazole catalyst C in a 20ml flask 3 h 8 AgN 7 , Then add 20mmol methylene aziridine and 10mmol alkyne, add 10ml toluene, and finally react at room temperature 25°C for 5h. After the reaction was completed, it was filtered, and the solvent was concentrated and evaporated by a rotary evaporator. The solid was subjected to silica gel column chromatography, and the column was washed with an eluent of petroleum ether:ethyl acetate=20:1 to obtain the target pyrrole compound with a yield of 92%. Purity≥99%.

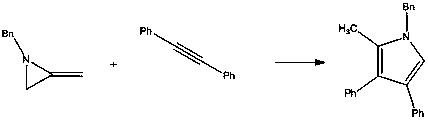

Embodiment 3

[0027]

[0028] Add 3mol% (relative to the alkyne) silver azotetrazole catalyst C in a 20ml flask 3 h 8 AgN 7 , Then add 20mmol methylene aziridine and 15mmol alkyne, add 15ml toluene, and finally react at room temperature 25°C for 6h. After the reaction was completed, it was filtered, and the solvent was concentrated and evaporated by a rotary evaporator. The solid was subjected to silica gel column chromatography, and the column was washed with an eluent of petroleum ether:ethyl acetate=20:1 to obtain the target pyrrole compound with a yield of 92%. Purity≥99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com