Passive protective net and installation method thereof

A passive protection and control device technology, applied in protective equipment, excavation, construction, etc., can solve problems such as difficult to find, unfavorable maintenance and maintenance, and achieve the effects of environmental protection, artificial greening, and detection of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

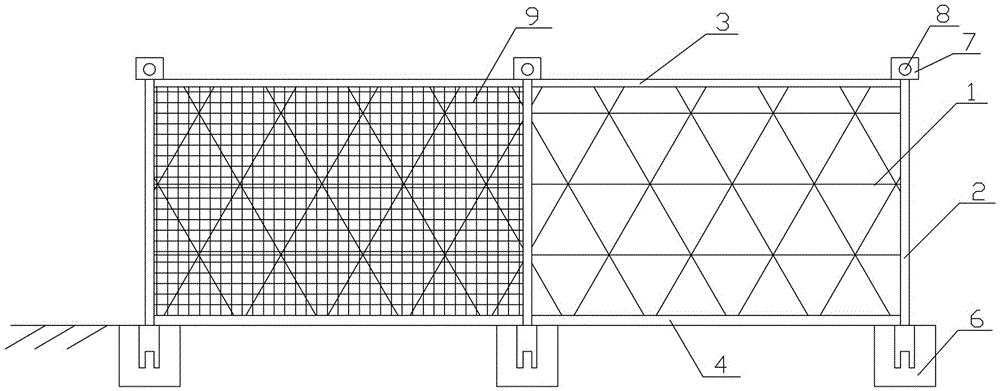

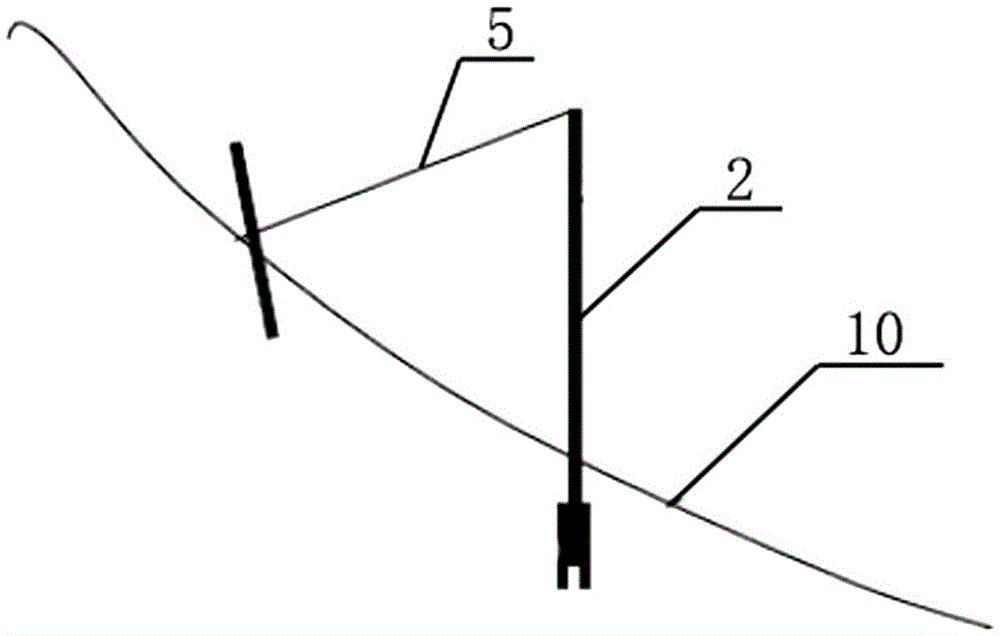

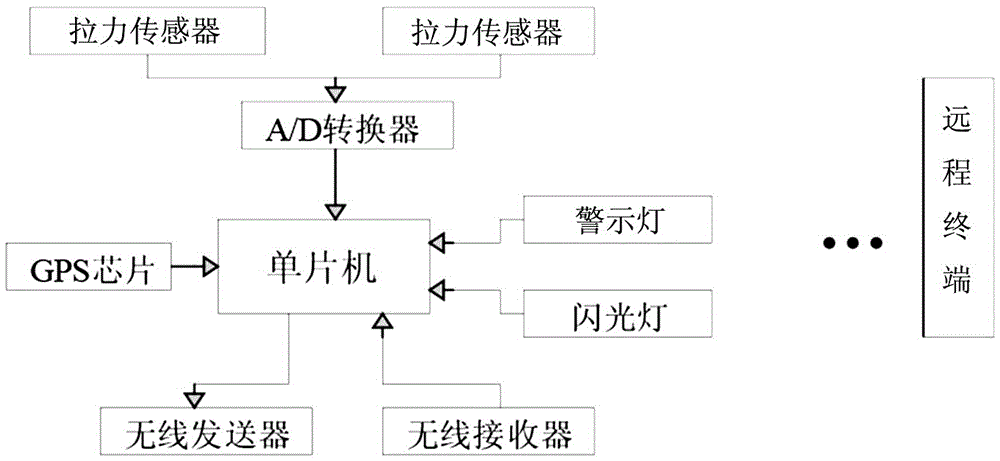

[0028] Embodiment 1: A kind of passive protective net, comprises steel wire netting, the steel column of fixing steel wire netting, upper support rope, lower support rope and pull-up anchor rope, and the bottom of steel column is fixedly installed on the base by connecting screw rod, and upper support rope 1. The lower support rope fixes the steel wire rope net and the steel column together, and pulls up the anchor rope to tighten and fix the top of the steel column. The passive protective net also includes a warning component, which includes a tension sensor set on the wire rope net, upper support rope or pull-up anchor rope, a control device set on the top of the steel column, a warning light and a buzzer; the control device includes GPS positioning modules, wireless transmission modules, control modules, and power modules that provide power for each module; the tension sensor is connected to the control module through an A / D converter, and the warning lights and buzzers are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com