Underwater pile foundation reinforcing device and construction method for reinforcing underwater pile foundations

A technology of reinforcement device and construction method, which is applied in basic structure engineering, restoration of basic structure, construction, etc., can solve the problems of high sealing requirements, large workload, and large traffic impact, and achieves convenient and fast construction and good social economy. benefits, the effect of avoiding structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

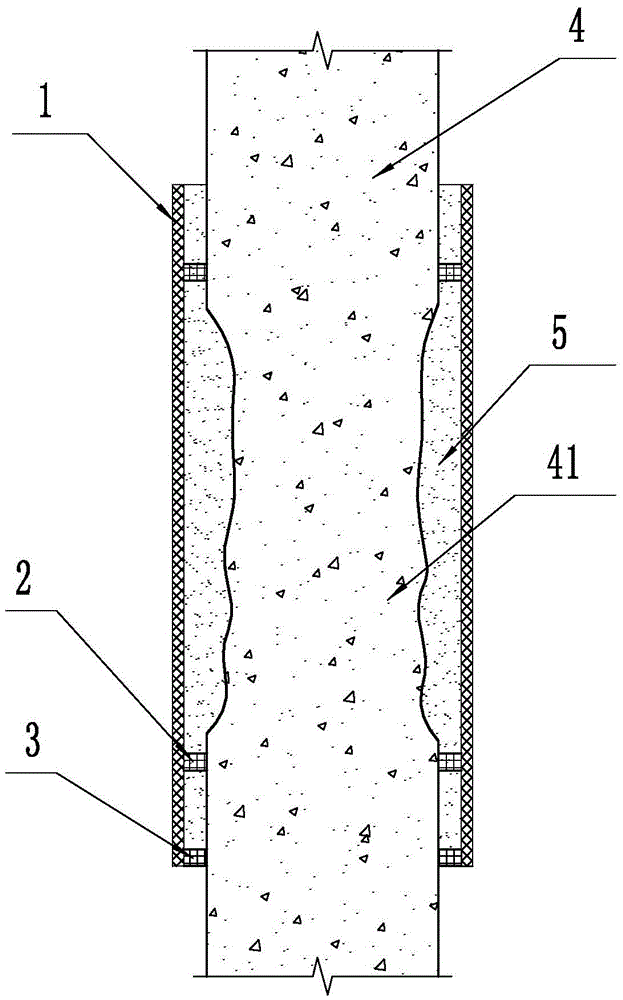

[0035] An underwater pile foundation reinforcement device, such as figure 1 As shown, the underwater pile foundation reinforcement device includes an FRP shell 1, a positioning block 2 and a sealing strip 3. The positioning block 2 is glued to the inside of the FRP shell by adhesive, and the sealing strip 3 is installed at the bottom of the FRP shell during construction. In the gap with the structure to be reinforced.

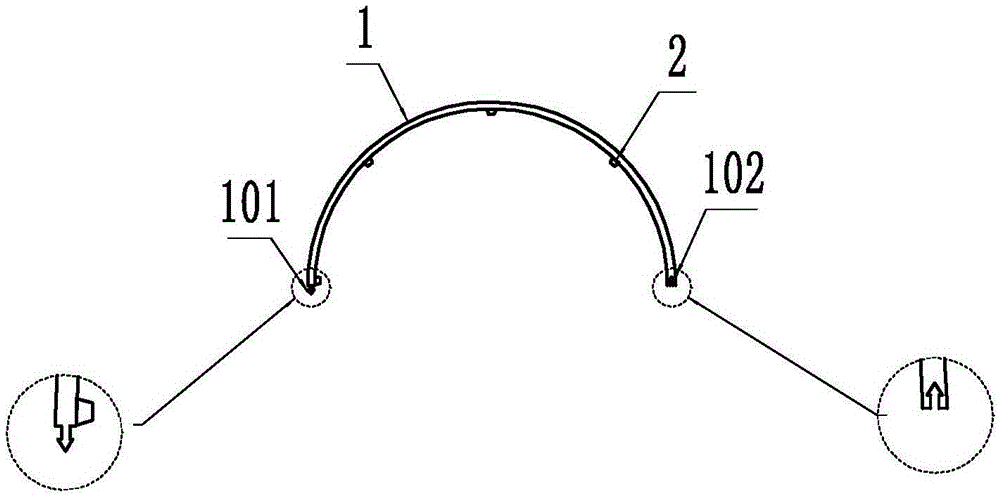

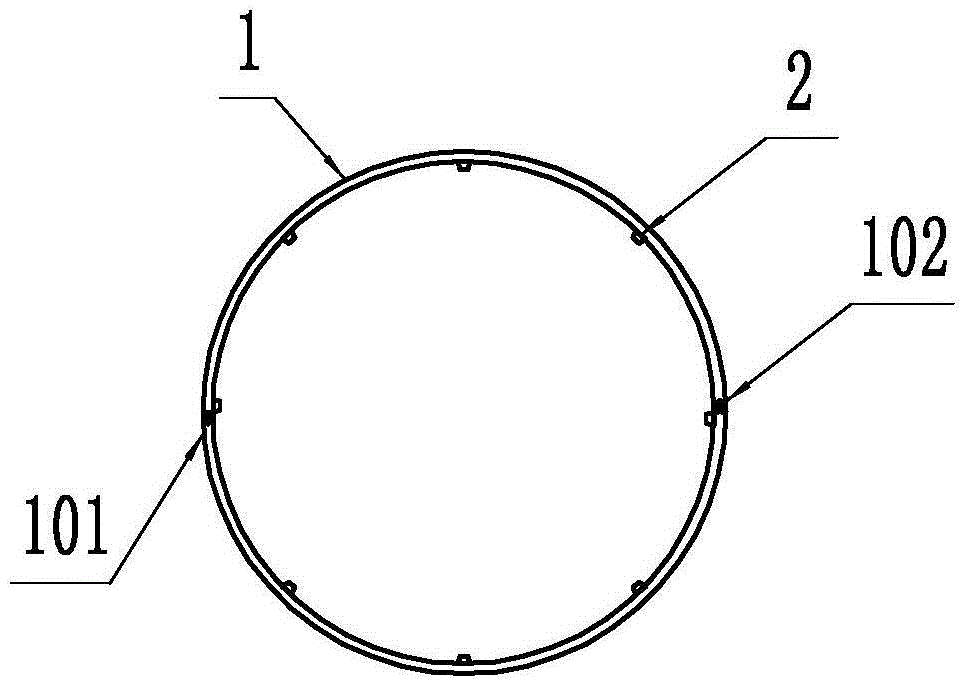

[0036] Such as figure 2 , image 3 As shown, the FRP shell is composed of two shells, each shell has a male joint 101 and a female joint 102 at both ends, and the two shells are assembled through the male joint 101 and the female joint 102 at both ends of each shell into a whole.

[0037] The thickness of the FRP shell is 1-5 mm, preferably 3 mm.

[0038] The FRP shell is made of n-layer reinforced fiber cloth and epoxy resin thermoplastic molding; the reinforced fiber cloth is woven from reinforced fiber warp yarn and reinforced fiber weft yarn; reinforce...

Embodiment 2

[0043] A construction method for underwater pile foundation reinforcement, which is a construction method using the underwater pile foundation reinforcement device described in Embodiment 1 for underwater pile foundation reinforcement, and it comprises the following steps:

[0044] A. Preparation before construction: Customize the FRP shell according to the size of the area to be reinforced by the concrete pile;

[0045] B. Install the FRP shell of the underwater pile foundation reinforcement device:

[0046] The two shells of the FRP shell are fastened and assembled on the area 41 of the concrete pile 4 to be reinforced through the male joint 101 and the female joint 102 at both ends of each shell. Since the glass fiber cloth and epoxy resin used for the shell are both light The FRP casing is fixed on the concrete pile 4 by the positive pressure provided by the extrusion deformation of the positioning block 3, and then the sealing strip 3 is installed in the gap between the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com