Binocular vision-based automobile chassis data measuring system and method thereof

A technology for automobile chassis and data measurement, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that automatic measurement cannot be realized, it is not easy to fix, and cannot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

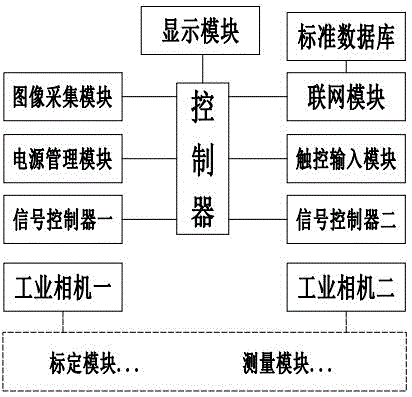

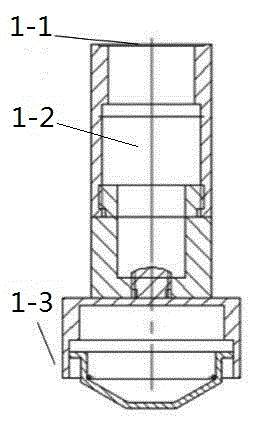

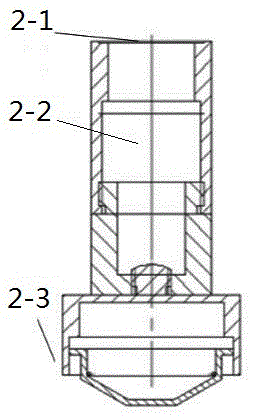

[0053] like figure 1 , a car chassis data measurement system based on binocular vision, including a handheld module, a standard database, three calibration modules 1 for installation in the undeformed area of the tested car chassis and a Several measurement modules 2 of

[0054] The handheld module includes a controller of X86 architecture, and the controller is connected with a display module, a touch input module, a networking module, an image acquisition module, a power management module, a signal controller one and a signal controller two, and the handheld module It also includes a high-resolution industrial camera one 3 and a high-resolution industrial camera two 4 for shooting the calibration module 1 and the measurement module 2; the signal controller one is connected with the industrial camera one 3, and the signal controller two is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com