Dyeing module applied to biological samples on glass slides and dyeing method thereof

A technology for biological samples and glass slides, applied in the fields of immunohistochemistry and immunocytochemistry staining, medical equipment and scientific instruments, can solve the problems of weakened staining, uneven staining, poor flexibility of reagents, etc., to ensure reliability and stability performance, ensuring reliability and stability, and avoiding the effect of dry film phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

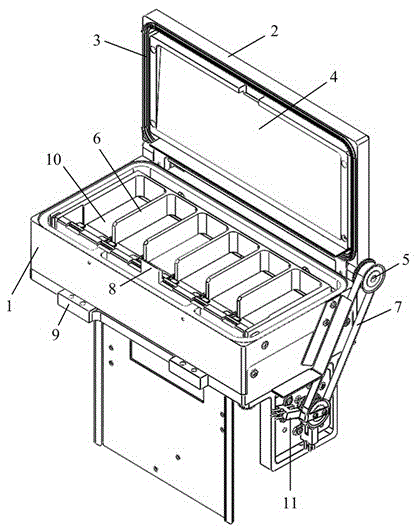

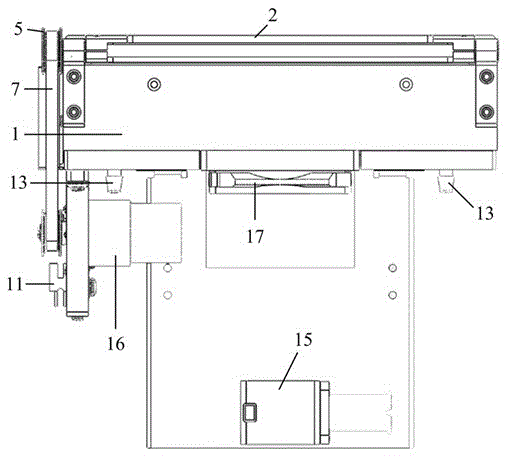

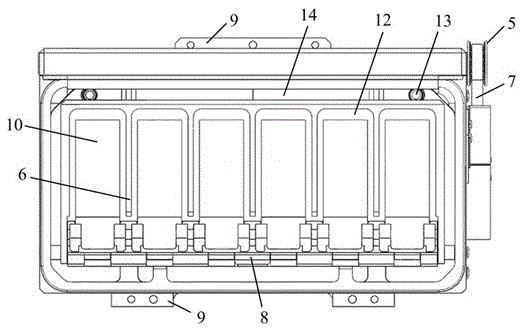

[0074] Such as Figure 1~5 As shown, the embodiment of the present invention provides a staining module for biological samples on glass slides, including a housing 1 with an upper opening, a module cover that is set at the upper opening of the housing 1 and is hinged to the housing 1 2. The casing 1 is provided with more than one module groove 12 for storing reagents along the transverse direction, one end of the module groove 12 is open and connected, and each module groove 12 is respectively provided with a module groove for placing glass slides. slice 19 and a horizontal support platform 10; one side of the housing 1 and a slice rack 8 is placed horizontally at the opening of the module slot 12, and more than one slice rack 8 is arranged at intervals along the transverse direction for holding glass slides. The spring clips 81 of the sheet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com