Area fingerprint sensor

A fingerprint sensor and area array technology, applied in the field of area array fingerprint sensors, can solve the problem of difficulty in reaching the size of the peripheral mechanism, and achieve the effects of reducing space, reducing the size of the mechanism, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

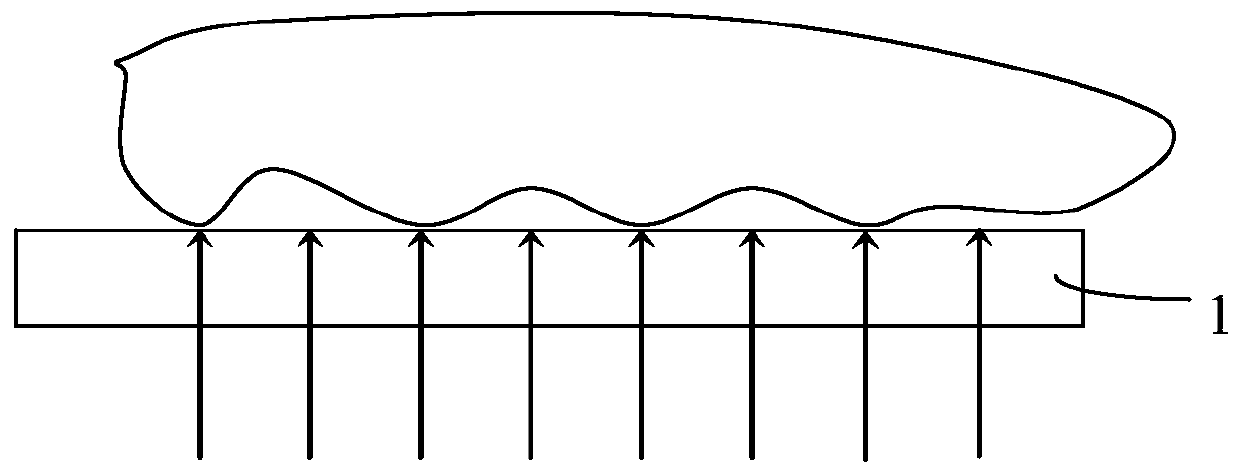

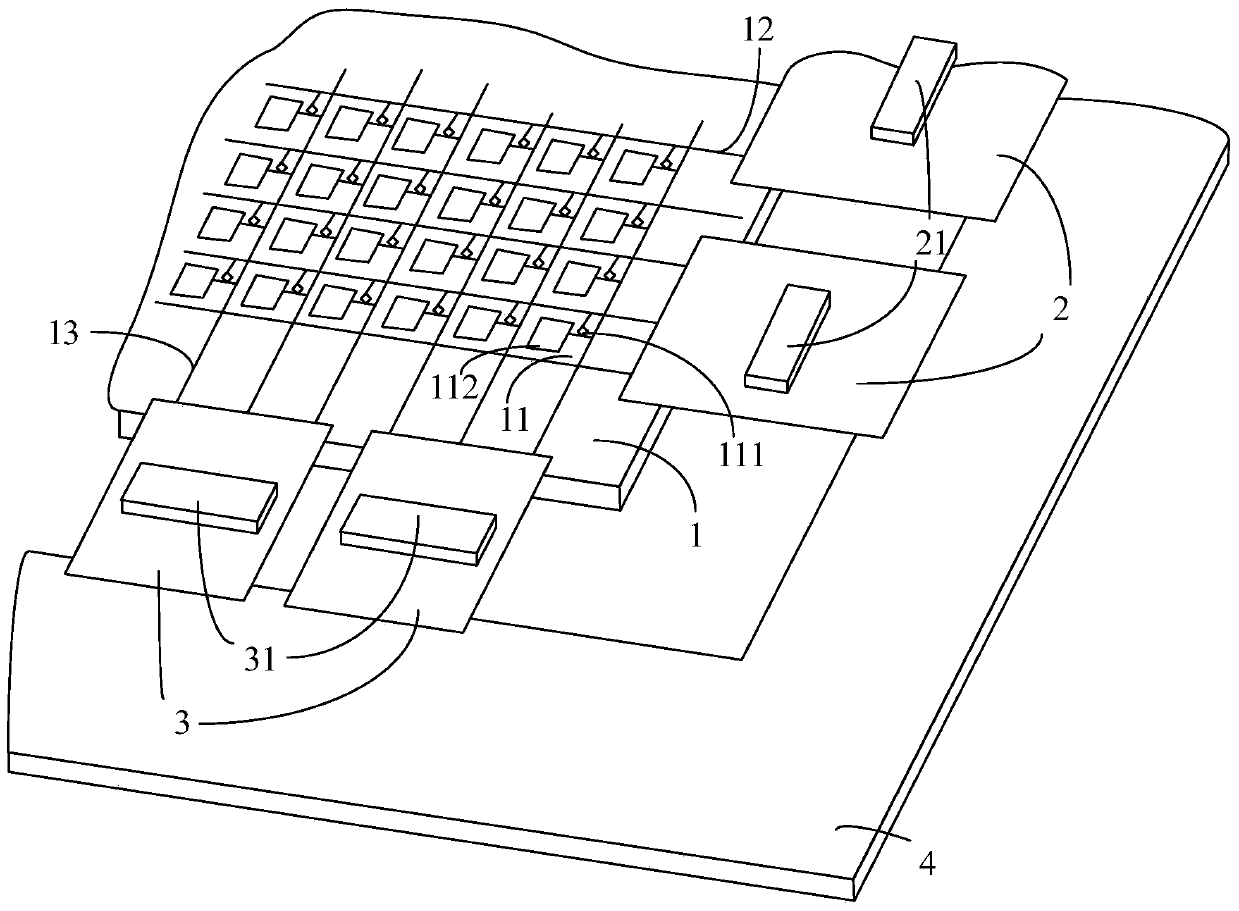

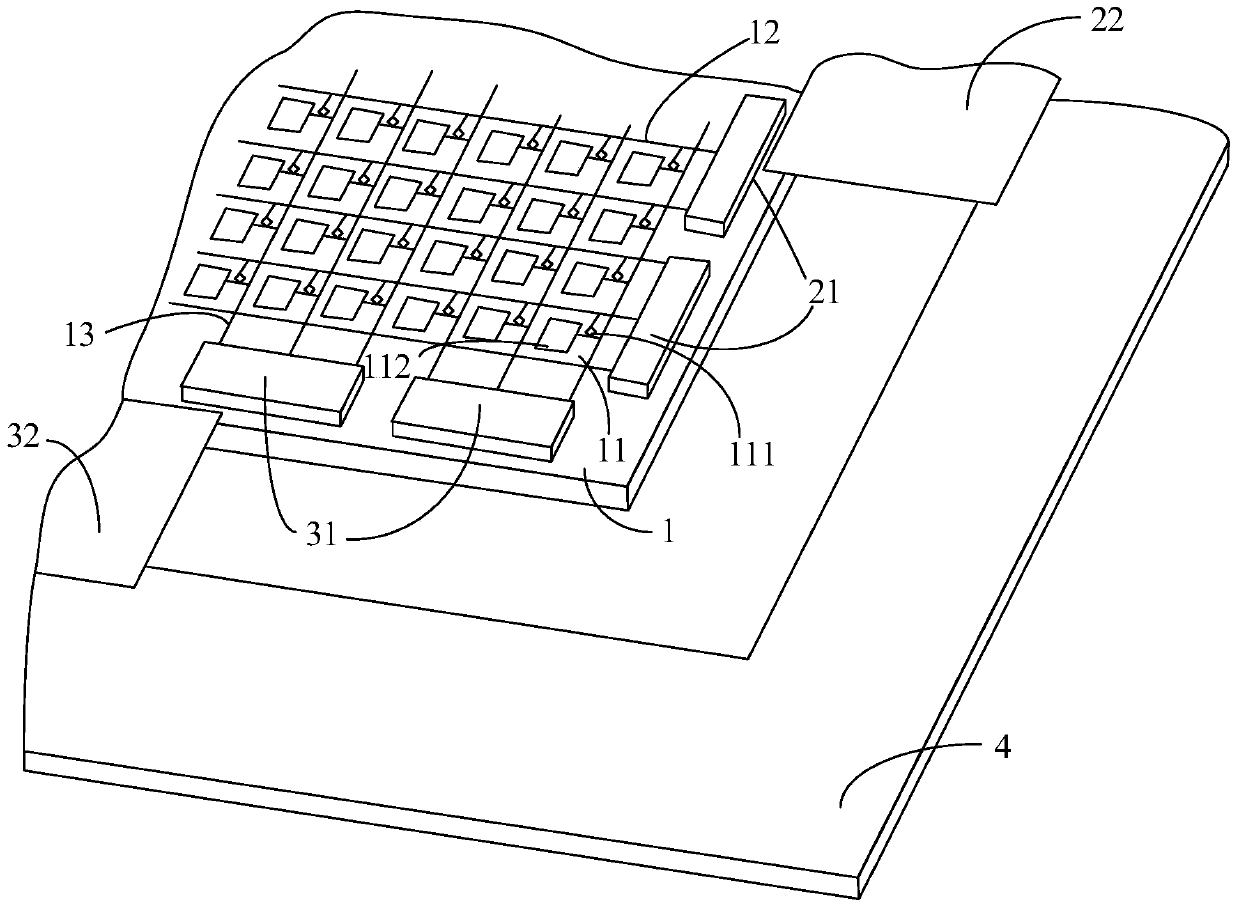

[0045] It can be seen from the background technology that in the prior art and products, whether the driver chip is figure 2 The COF module method of the chip on the film shown is still as follows image 3 The COG binding method shown is still as Figure 4 In the ASG, LTPSG, or OSG circuit mode, the area outside the pixel unit array of the area fingerprint sensor is relatively large: the driving signal input and data signal output of the pixel unit array are along the row and column directions respectively. . Correspondingly, the driving unit and the signal readout unit need to be respectively located in the row and column directions of the pixel unit array. That is to say, there needs to be enough space for setting the drive unit and the signal readout unit in both the row and column directions, thereby limiting the size of the frame of the area fingerprint sensor and restricting the reduction of the frame of the area fingerprint sensor.

[0046] In order to solve the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com