Power supply equipment with segmented overlapping self-decoupling rectangular coil structure

A technology of rectangular coils and segmental overlapping, applied in the direction of electrical components, circuit devices, etc., can solve the problems of electric vehicle industrialization difficulties, low equipment operating efficiency, equipment stop charging, etc., to reduce the level of magnetic field exposure and power transmission performance Stable and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

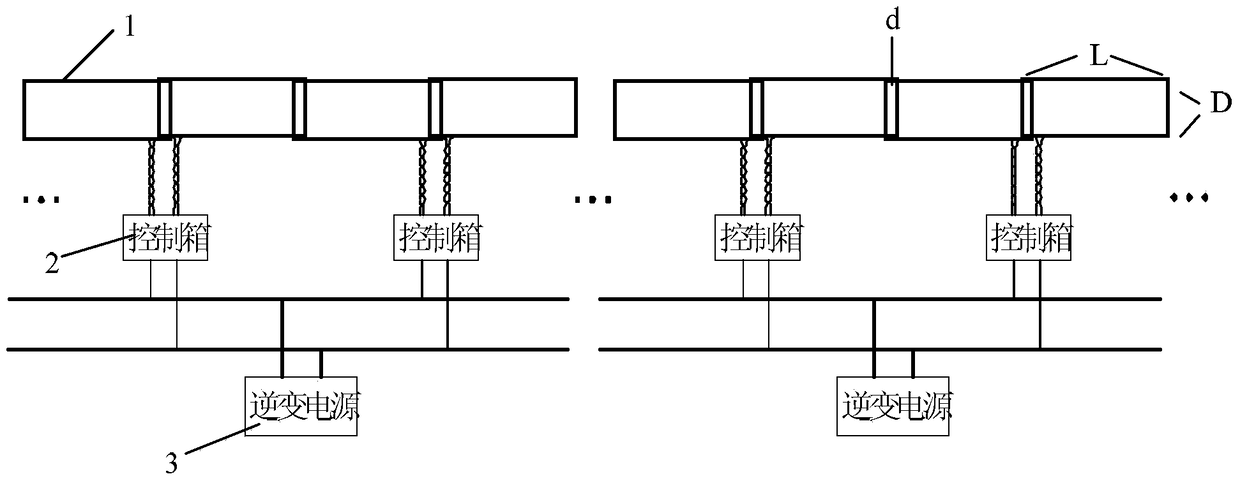

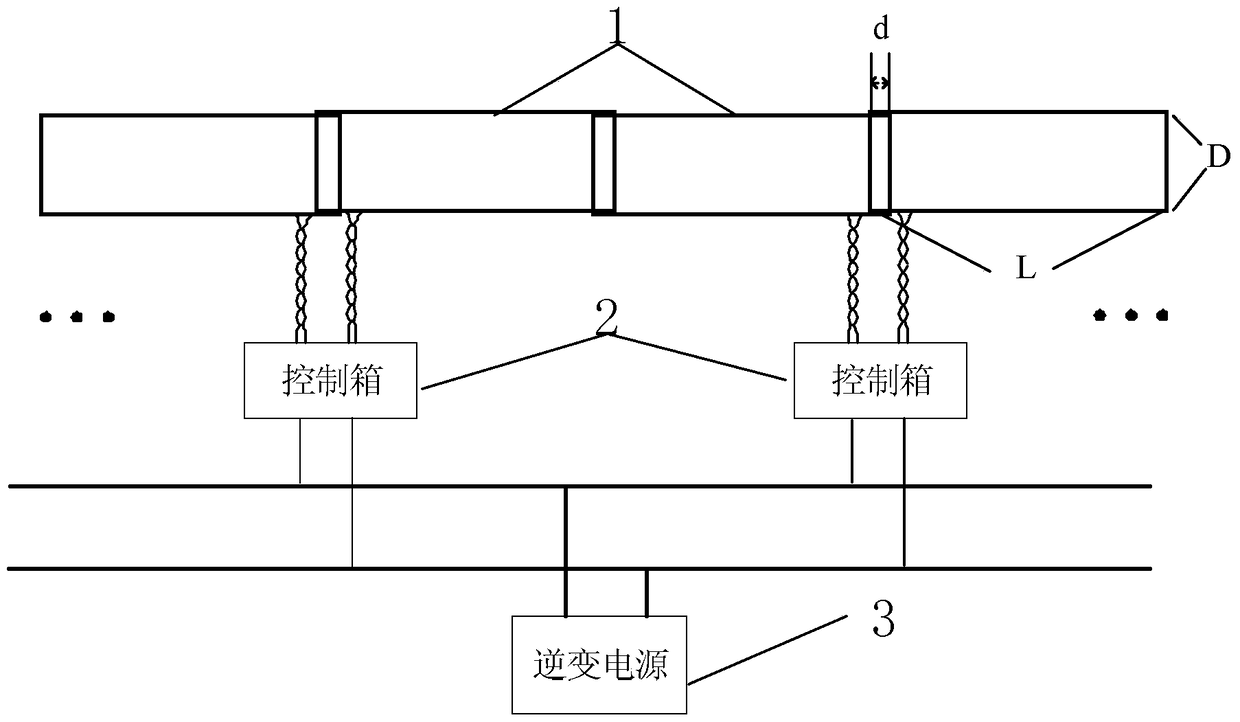

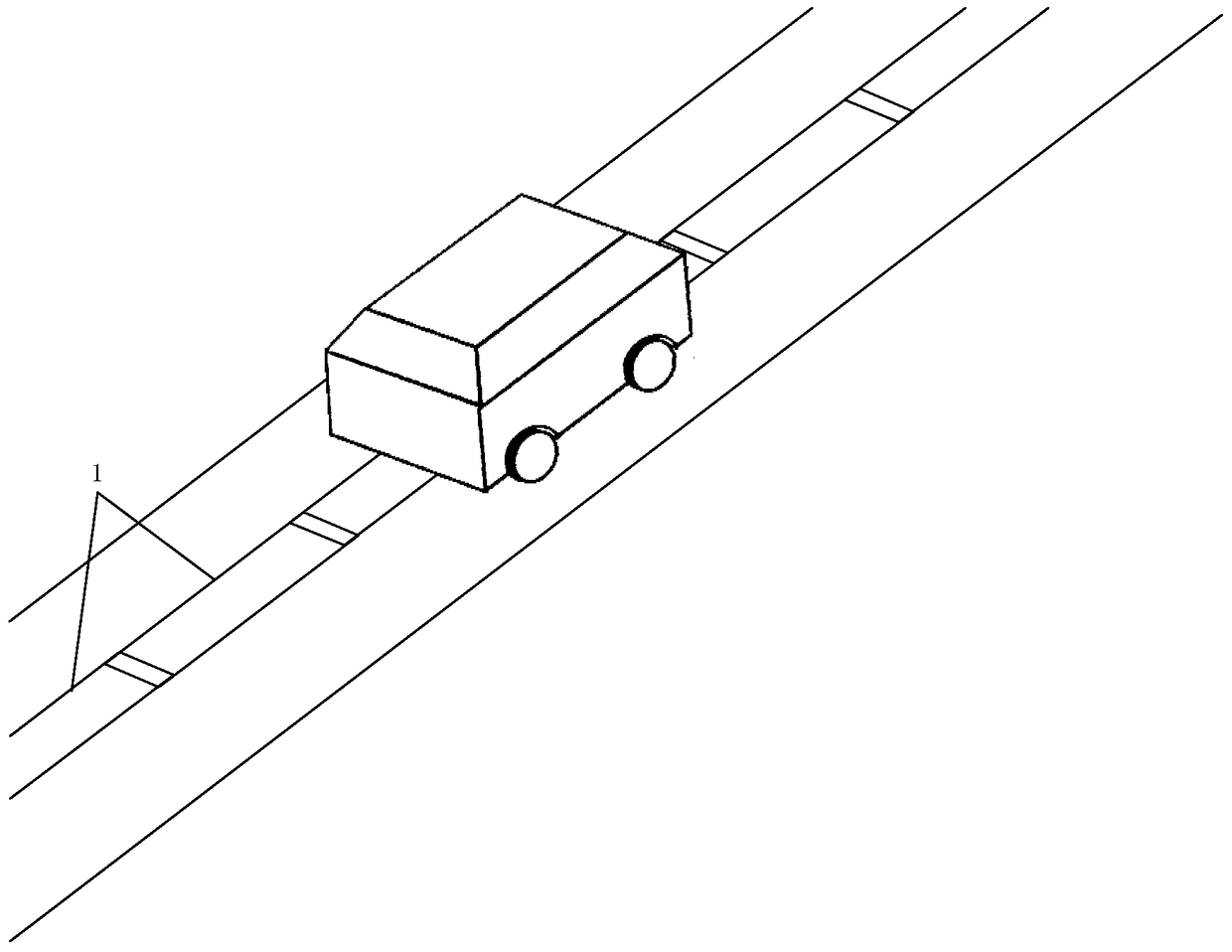

[0024] Specific implementation mode 1. Refer to figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment in detail. The power supply device of the segmented overlapping self-decoupling rectangular coil structure applied to the wireless power supply of mobile transportation equipment described in this embodiment includes a rectangular coil 1, b control boxes 2 and c inverters. Variable power supply 3; a is an integer greater than or equal to 2, b is an integer not less than a / 2, and c is a positive integer;

[0025] a rectangular coil 1 constitutes a power supply track;

[0026] A rectangular coils 1 are tiled and arranged sequentially along the actual direction of motion, the front end of the latter rectangular coil 1 is pressed against the rear end of the previous rectangular coil 1, and the overlapping area is equal in width; the width d of the overlapping area of adjacent rectangular coils 1 is smaller than that of the rectangular coil 1 Coil 1 of length...

specific Embodiment approach 2

[0034] Specific Embodiment 2. This embodiment is a further description of the power supply device of the segmented overlapping self-decoupling rectangular coil structure applied to the wireless power supply of mobile transportation equipment described in the first embodiment. In this embodiment, the turns of the rectangular coil 1 number greater than or equal to 2.

specific Embodiment approach 3

[0035] Specific Embodiment 3. This embodiment is a further description of the power supply equipment with a segmented overlapping self-decoupling rectangular coil structure applied to wireless power supply for mobile transportation equipment described in Embodiment 1. In this embodiment, b control boxes 2 The connecting wires with a rectangular coil 1 are twisted with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com