A non-Newtonian fluid thickening polishing method and polishing system based on magnetic field assistance

A non-Newtonian fluid, magnetic field-assisted technology, applied in the field of polishing methods and polishing systems, can solve the problems of weakened thickening effect, narrow thickening area, and low polishing efficiency, and achieves improved processing efficiency, uniform magnetic field intensity distribution, and adaptability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

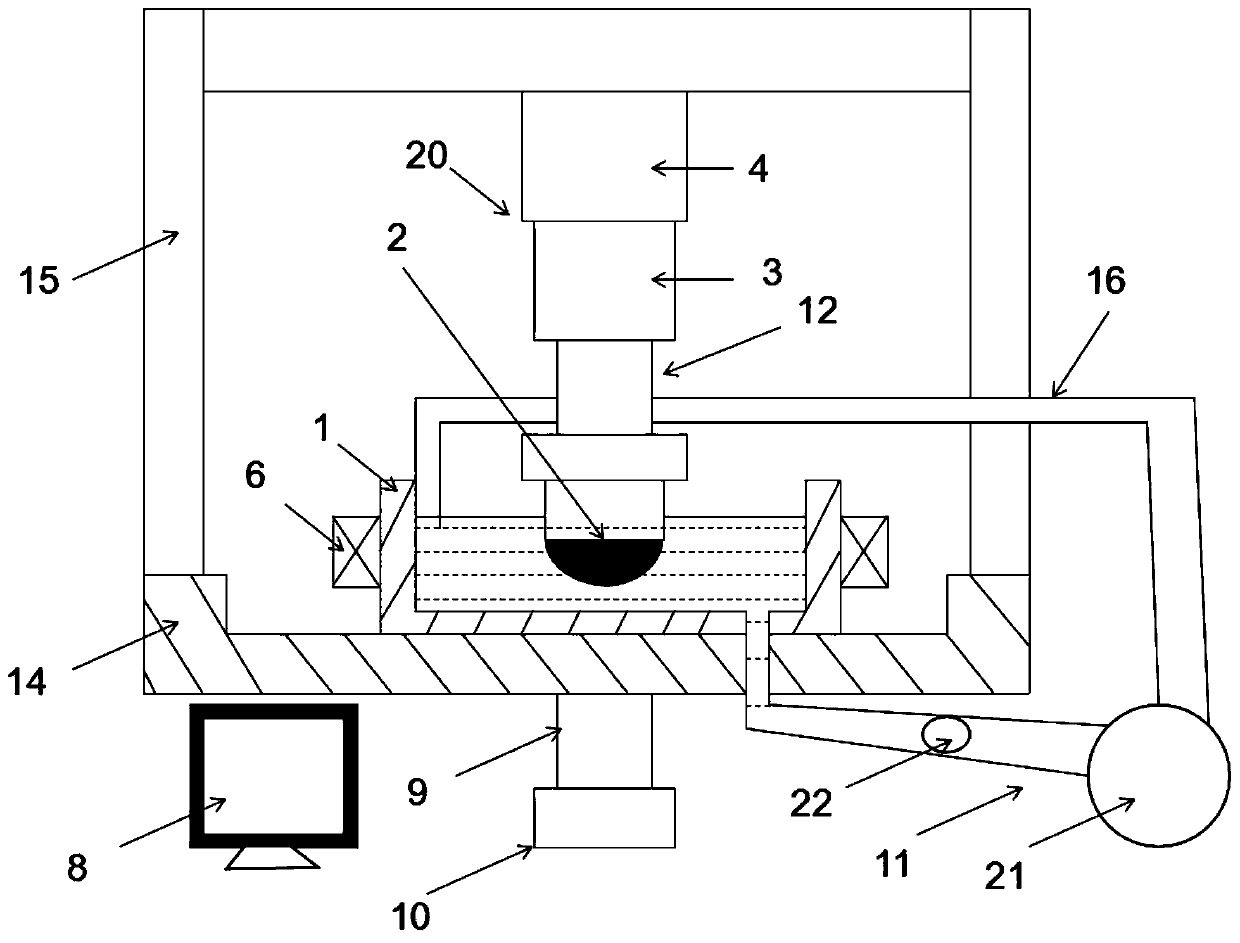

[0033] The polishing method based on magnetic field-assisted non-Newtonian fluid thickening of the present embodiment comprises the following steps:

[0034] S1: Fix the polishing liquid tank 1 on the workbench 14, add the non-Newtonian fluid polishing liquid with magnetorheological properties into the polishing liquid tank 1, and then use the clamping device 20 with a driving system to soak the polished workpiece 2 in the above-mentioned In the non-Newtonian fluid polishing fluid, and open the magnetic field generator 6, the viscosity of the non-Newtonian fluid polishing fluid is increased;

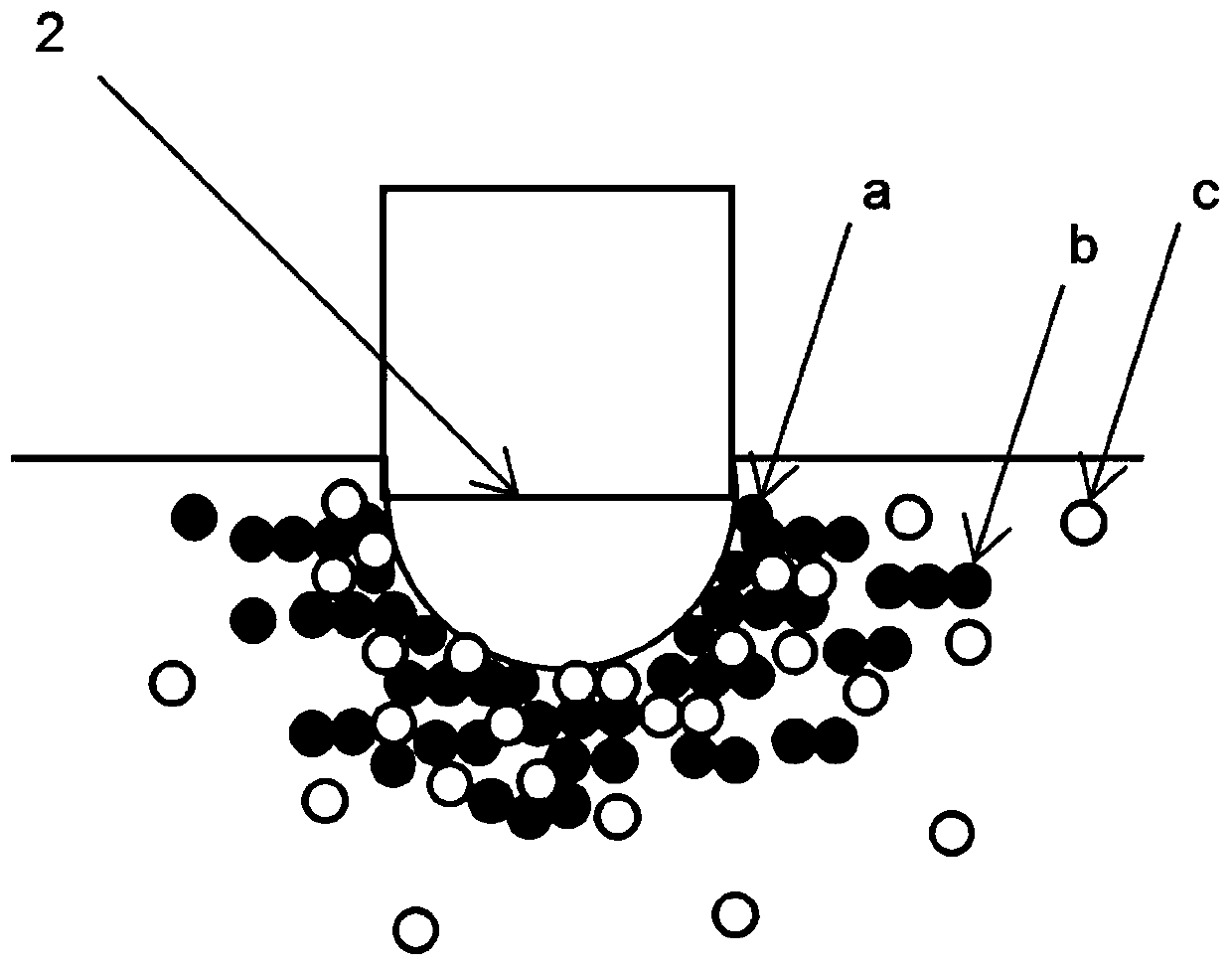

[0035] S2: under the action of the above-mentioned drive system, the clamping device 20 drives the polishing workpiece 2 to rotate so that the polishing workpiece 2 and the non-Newtonian fluid polishing liquid undergo relative motion, and the abrasive grains in the non-Newtonian fluid polishing liquid cut the surface of the polishing workpiece 2, That is, the polishing process is complet...

Embodiment 2

[0046] The polishing method based on magnetic field-assisted non-Newtonian fluid thickening of the present embodiment comprises the following steps:

[0047] S1: Fix the polishing liquid tank 1 on the workbench 14, add the non-Newtonian fluid polishing liquid with magnetorheological properties into the polishing liquid tank 1, and then use the clamping device 20 with a driving system to soak the polished workpiece 2 in the above-mentioned In non-Newtonian fluid polishing fluid;

[0048] S2: Turn on the polishing liquid circulation system 11 for controlling the stability of the non-Newtonian fluid polishing liquid in the polishing liquid tank 1;

[0049] S3: Turn on the magnetic field generating device 6 to increase the viscosity of the non-Newtonian fluid polishing solution;

[0050] S4: Under the action of the above-mentioned driving system, the clamping device 20 drives the polishing workpiece 2 to rotate so that the polishing workpiece 2 and the non-Newtonian fluid polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com