Secondary-etching double-sided circuit board and processing technique thereof

A double-sided circuit board, secondary etching technology, used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of uncontrolled product quality, long cycle time, and inability to meet customer requirements, and simplify production. Process and operation difficulty, the effect of reducing PCB production costs and shortening the production process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

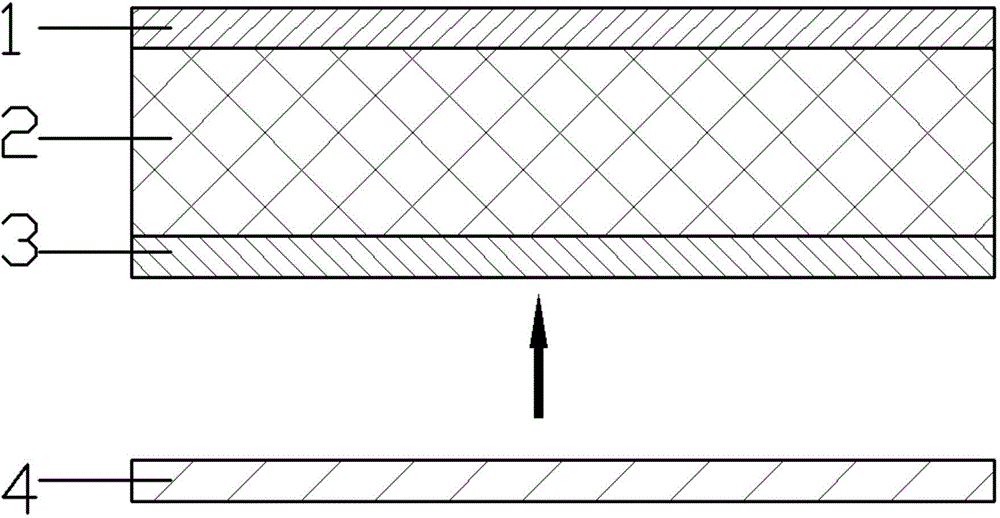

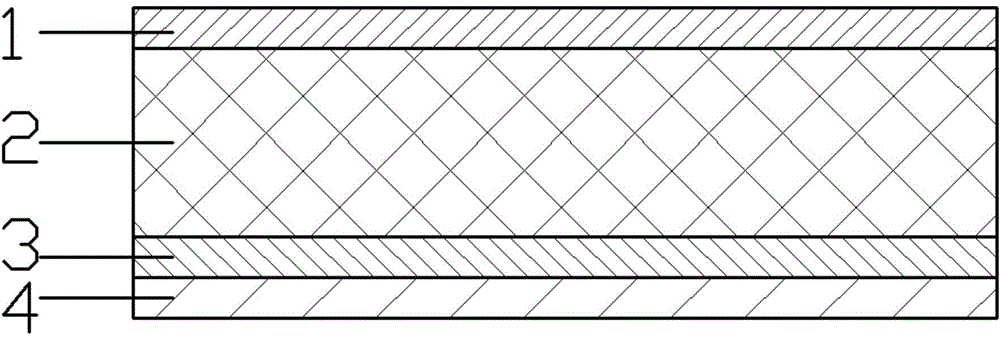

[0027] refer to image 3 As shown, a double-sided circuit board for secondary etching includes: GTL circuit layer 1, insulating PP layer 2 and GBL circuit layer, and the GBL circuit layer is composed of a GBL inner circuit layer 3 and a GBL outer circuit layer 4. The GTL line layer 1 and the GBL inner line layer 3 are connected to the insulating PP layer 2 at the same time, the GBL outer line layer 4 is covered on the GBL inner line layer 3, and the size of the GBL outer line layer 4 is larger than that of the GBL inner line layer 3 size.

[0028] The size of the GBL outer circuit layer 4 is 0.05 mm larger than the size of the GBL inner circuit layer 3 .

[0029] The secondary etched double-sided circuit board is formed through a secondary circuit processing process.

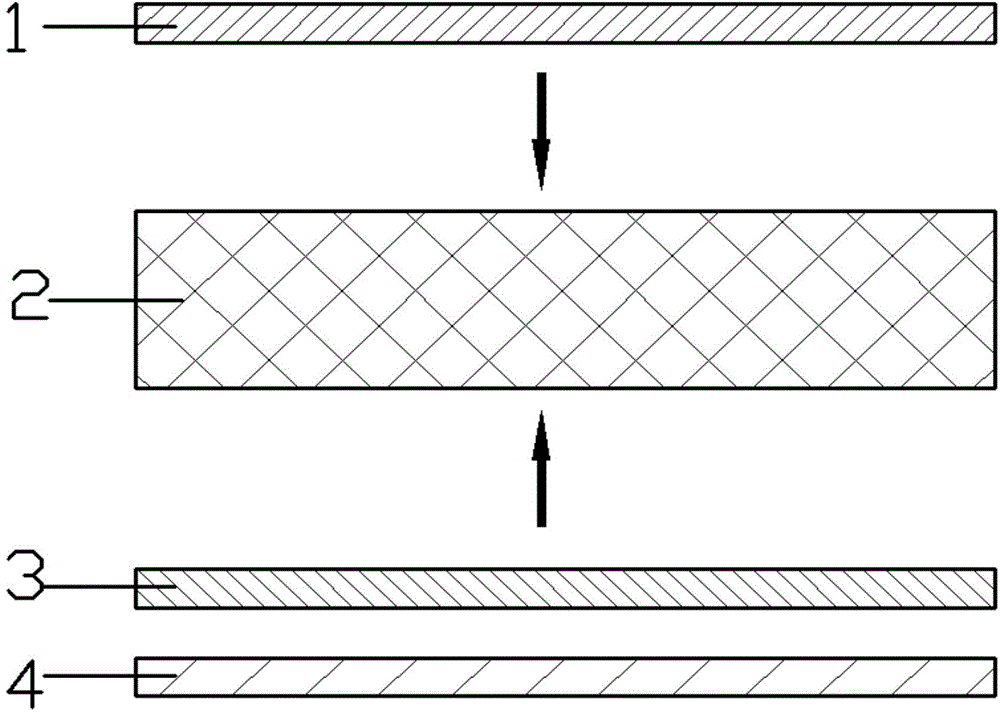

[0030] Such as figure 1 As shown, the first circuit processing technology includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com