Transition body between tower sections of wind turbine, and tower of wind turbine comprising transition body

A technology of wind power generation equipment and transition body, which is applied in the direction of wind turbines consistent with the wind direction, the assembly of wind turbines, the configuration of installation/supporting wind turbines, etc., which can solve the problems of increasing installation costs and not having force line flux. , to achieve simple installation, reduce the risk of local material damage, and reduce the effect of stress peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

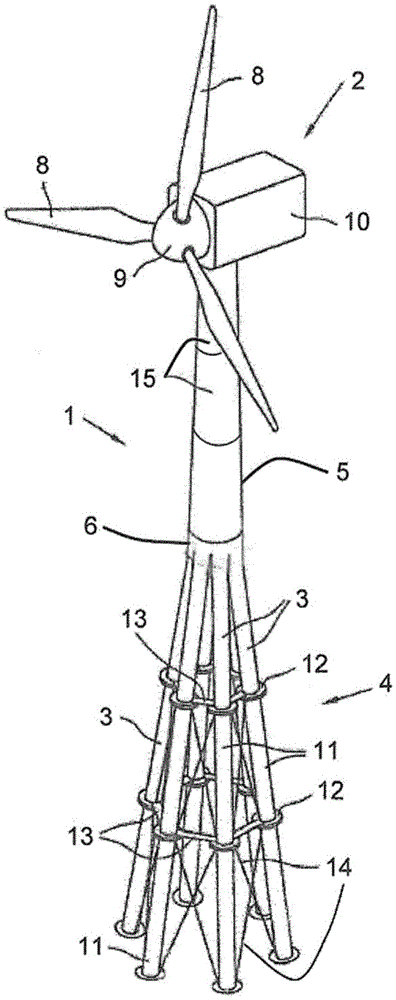

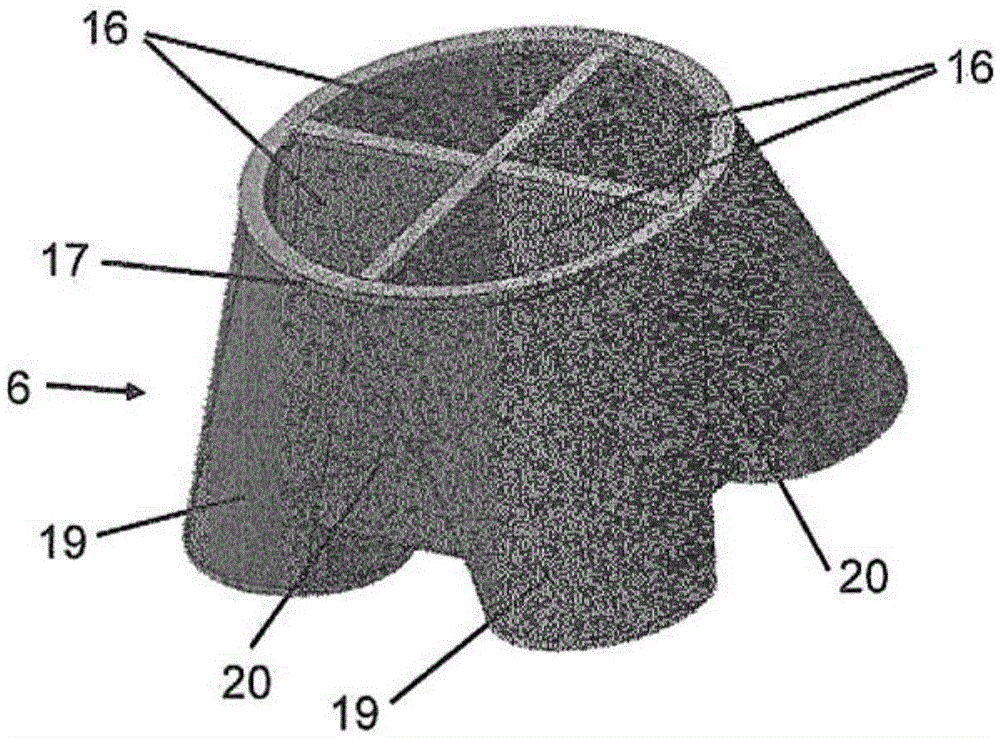

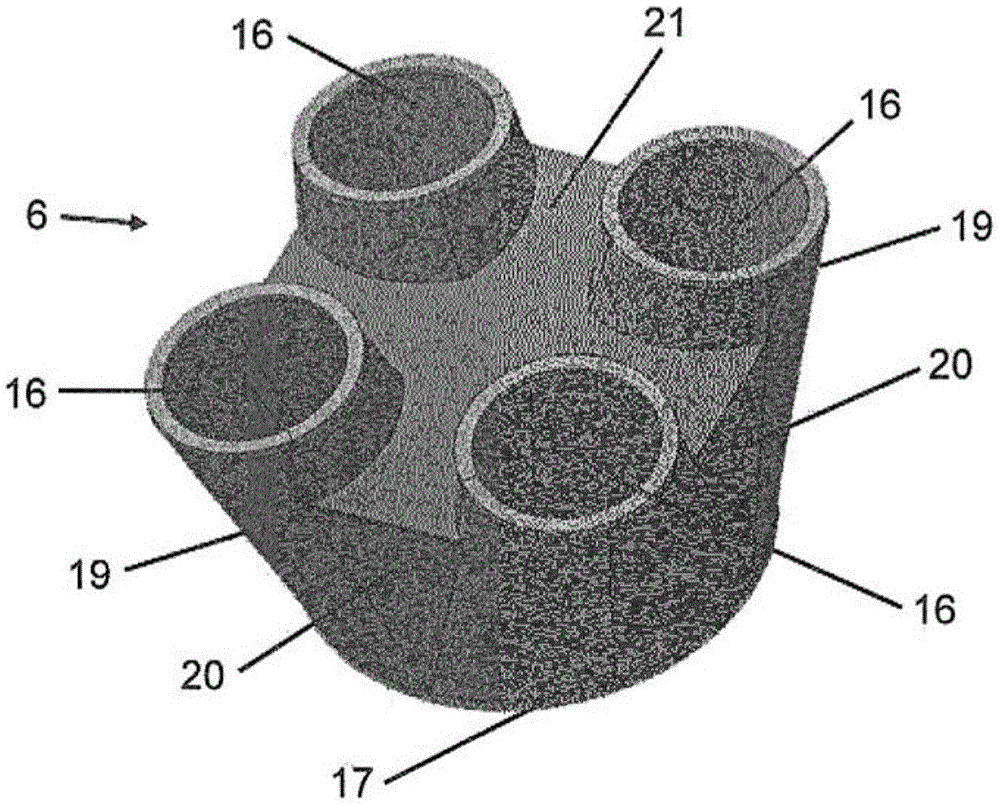

[0036] attached figure 1 The tower 1 of the wind power plant 2 shown in the Fig. The transition body 6 between the lower tower section is formed. On the upper end of the tubular tower of the upper tower section 5 is mounted a wind power plant 2 which is mounted in rotation about an axis extending substantially vertically. The wind power plant 2 includes a rotor 7 rotatable about a horizontal axis with three rotor blades 8 . Furthermore, the rotor blades 8 are mounted rotatably about their longitudinal extent on the hub 9 of the wind power plant 2 in order to be able to operate substantially infinitely towards the wind. In the so-called pod enclosure A generator is set in 10, the shaft of which is rotationally and rigidly connected with the rotor through a transmission mechanism and a coupling.

[0037] The lower tower section 4 has six corner brackets 3 in the illustrated and thus preferred tower 1 , wherein more or less than six corner brackets 3 can also be present. Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com