Marine constant-tension winch

A constant tension, winch technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of output shaft damage, cable breakage, motor damage, etc., and achieve the effect of reducing damage frequency, saving electric energy, and saving ship energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

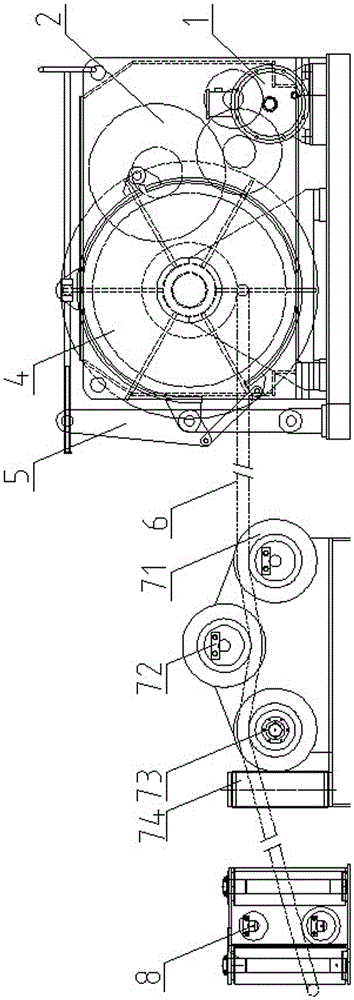

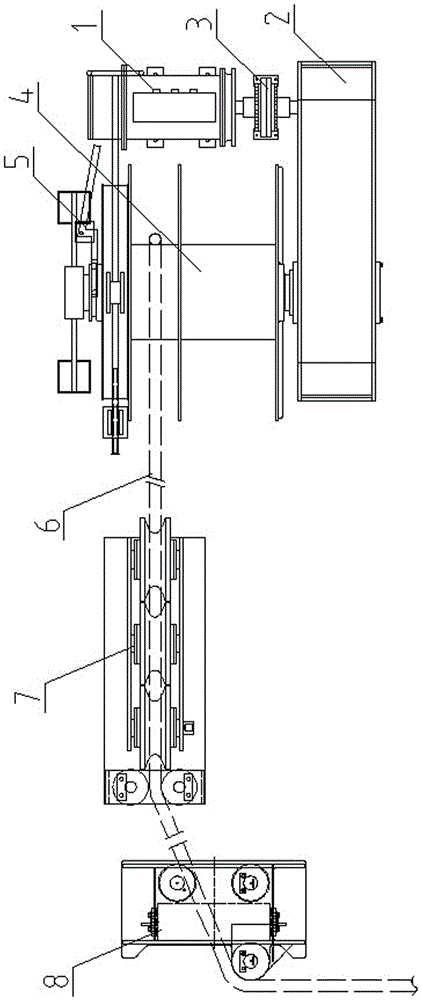

[0015] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0016] As shown in the figure, an electric constant tension winch includes a winch base for fixing the winch. A motor 1, a reduction box 2 and a reel 4 are installed on the base. The motor 1 is a variable frequency brake motor, and the motor 1 The reel is driven by the reducer 2. A magnetic powder clutch 3 is installed between the output shaft of the motor 1 and the input shaft of the reducer 2. The reel 4 is wound with a cable 6. The reel 4 is a device for storing the cable and connecting the load. The cable 6 If the number of layers exceeds three, an automatic cable discharge device can be added in front of the drum to ensure that the cables are arranged neatly. The reel is provided with manual braking device 8. Cable 6 can be a nylon rope or a steel wire rope, which is set according to load requirements. The cables pass through the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com