Manufacturing method of 'upward water flowing' energy circulator

A technology of water flowing upwards and energy circulation, applied in chemical instruments and methods, water supply devices, drinking water devices, etc., can solve problems such as not having the advantage of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

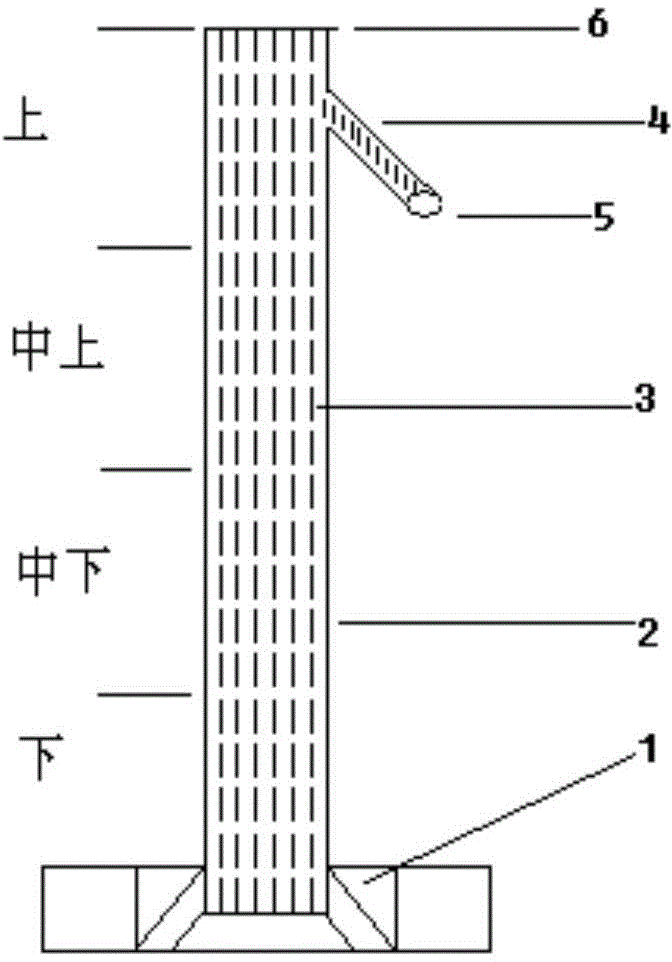

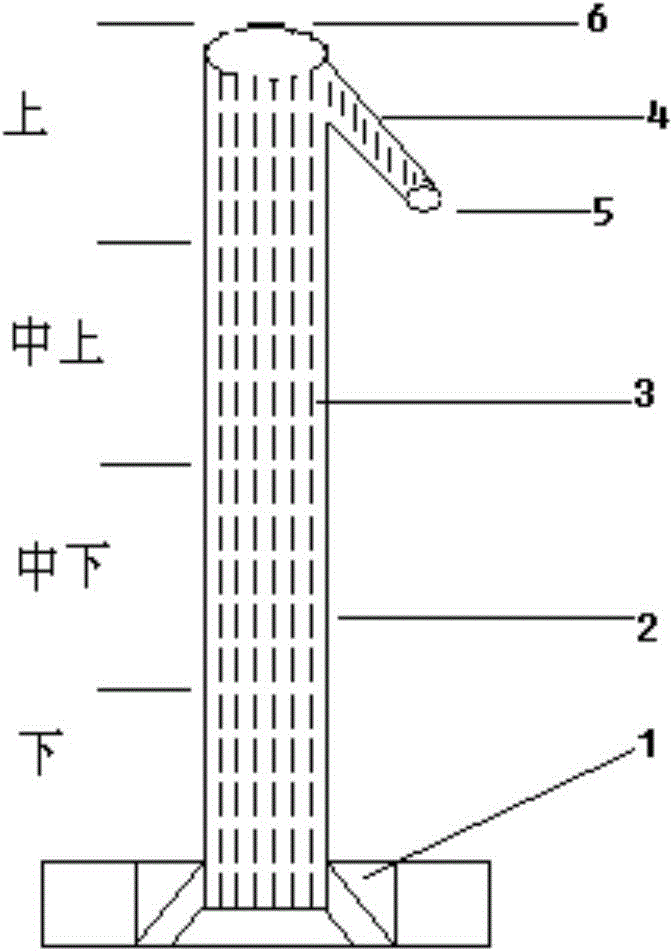

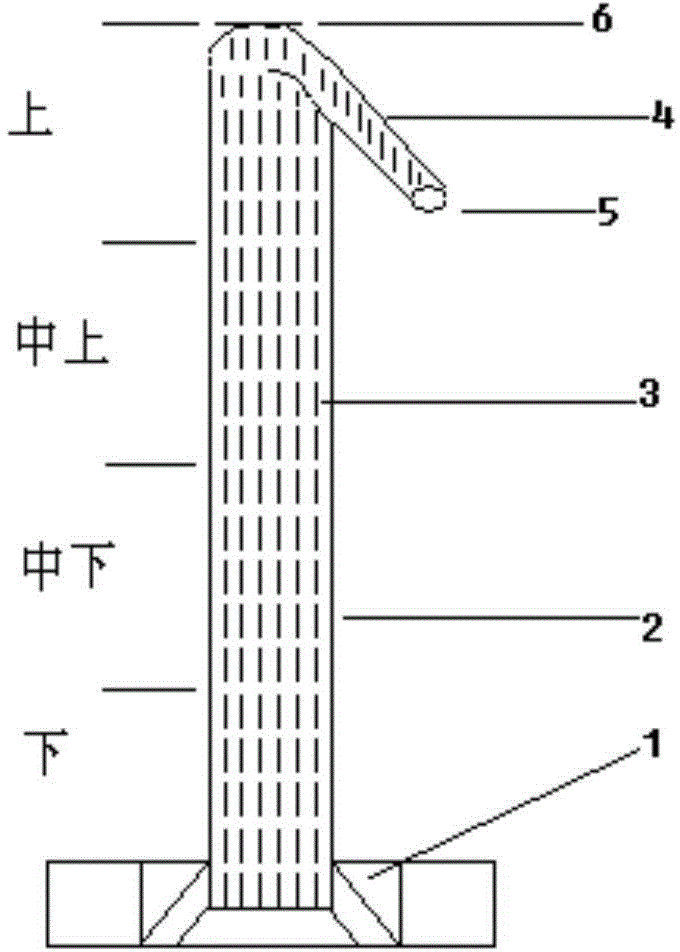

[0074] to attach figure 1 , attached figure 2 , attached image 3 As an example to explain the specific operation steps:

[0075] figure 2 and image 3 and figure 1 The difference is only the difference in the shape of the parts in the structure, such as the position and shape of the pipe outlet body (4), its basic structure is the same as figure 1 There is no difference in the structure of the representation, so the following only uses figure 1 structure to illustrate.

[0076] figure 1 It is a schematic diagram of the structure of the "water upward flow" equipment, in which 1 is the immersion body, 2 is the outer casing of the pipe, 3 is the capillary pipe inside the pipe, 4 is the water outlet of the pipe, 5 is the water outlet, and 6 is the top horizontal line. As the name implies, the submerged body (1) is the part soaked in water, including the part soaked in the water of the outer shell of the pipe (2) and the part soaked in the water of the capillary pipe (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com